Cable car hanging structure applied to rural intelligent logistics distribution

A logistics distribution and intelligent technology, which is applied in the direction of motor vehicles, cable railways, railway vehicles, etc., can solve the problems of fixed distance, logistics impact, inability to adjust the loading weight of cable cars, etc., and achieve the effect of increasing the length of force and relieving local force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

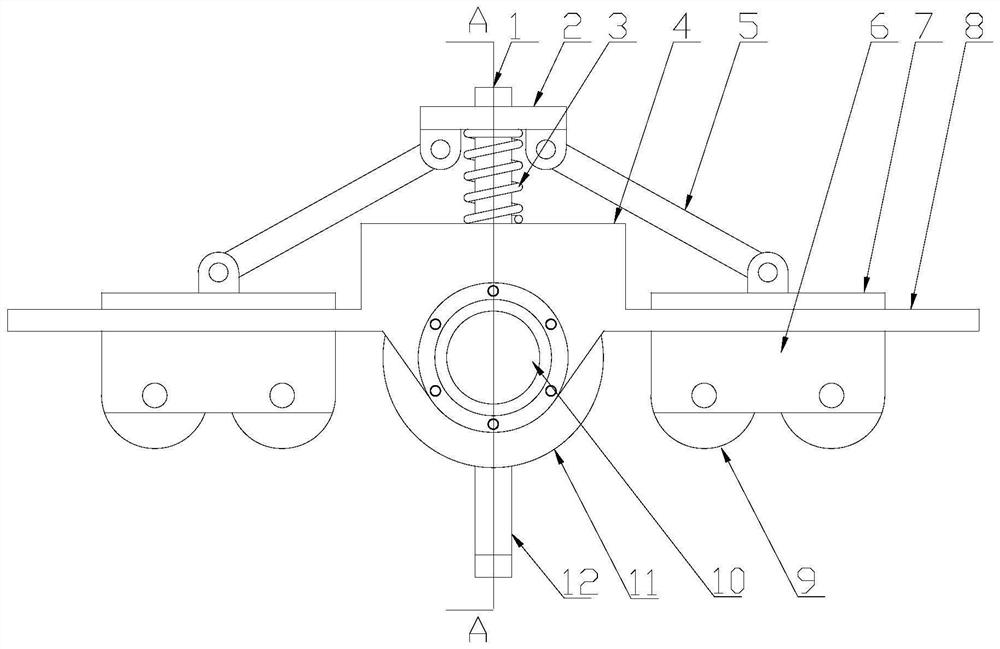

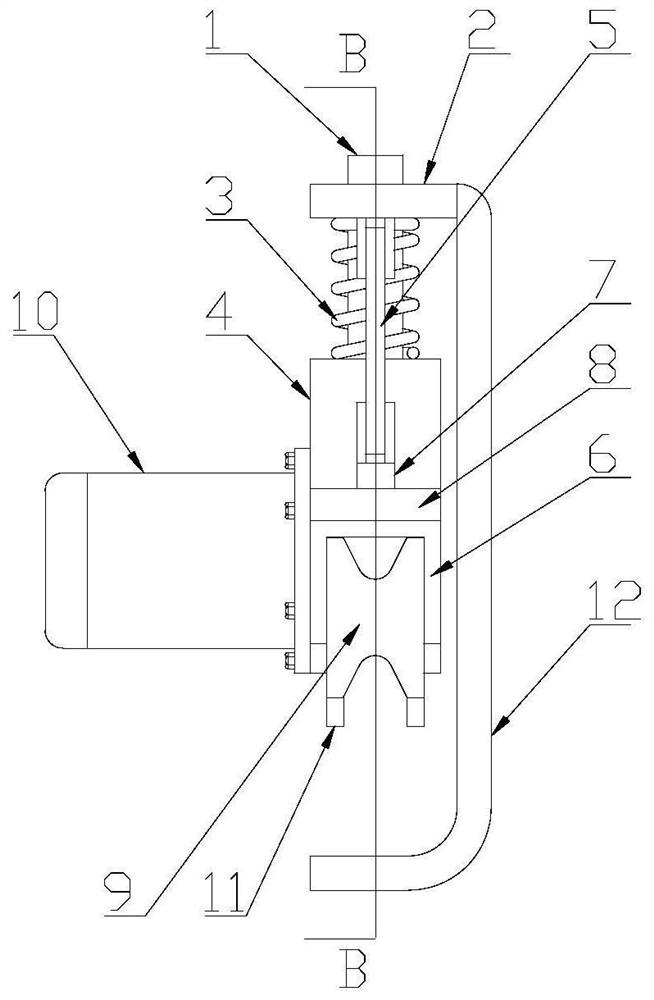

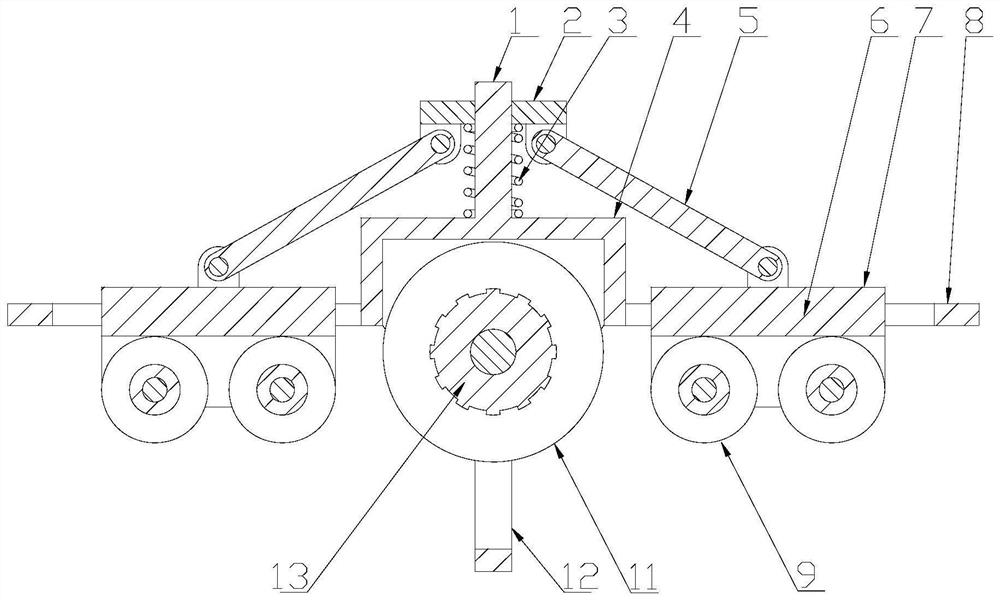

[0023] A cable car hanging structure applied to rural smart logistics distribution described in this embodiment includes a mounting frame 4, a running wheel 13 is installed on the bottom of the mounting frame 4, and a driving wheel is also installed on the mounting frame 4. 13 rotating drive motor 10, both sides of the mounting bracket 4 are connected to support plates 8, and the bottoms of the two support plates 8 are equipped with pulleys 9, and the pulleys 9 and support plates 8 are slidingly fitted, and the pulleys 9 Able to move laterally along the support plate 8, a load-bearing plate 2 is arranged above the mounting frame 4, and a hanger 12 for connecting with a cable car is connected to the load-bearing plate 2, and a support spring is arranged between the load-bearing plate 2 and the mounting frame 4 3. Both sides of the support spring 3 are provided with a support rod 5 , one end of the support rod 5 is hinged to the bearing plate 2 , and the other end is hinged to th...

Embodiment 2

[0026] In this embodiment, the technology will be further explained. The support plate 8 is provided with a chute extending laterally. The top of the wheel frame 6 of the pulley 9 is provided with a limiting rib 7, and the limiting rib 7 is inserted into the chute upwards. Inside, the support rod 5 is connected to the limiting rib 7 .

[0027] The pulley 9 cooperates with the chute by setting the limit rib 7 on the wheel frame 6, and can slide along the chute. When the pulley 9 was on the steel cable, the gravity of the cable car acts on the load-bearing plate 2 through the hanger 12, and then acts on the load-bearing plate 2. On the installation frame 4, the pulley 9 is pressed on the steel cable by the support plate 8, so that the support plate 8 and the pulley 9 are in a bonded state. Make a push.

Embodiment 3

[0029] In this embodiment, the technology will be further described. The center of the top of the mounting frame 4 is provided with a guide column 1. The lower end of the guide column 1 is connected to the mounting frame 4, and the upper end passes through the center of the load-bearing plate 2 to slide and fit with the load-bearing plate 2. The support spring 3 is sleeved on the outside of the guide post 1 .

[0030] The guide column 1 is slidably matched with the bearing plate 2, which will be used as a guiding and limiting structure when the bearing plate 2 moves up and down. At the same time, the support spring 3 is set outside the guide column 1 to prevent the support spring 3 from shifting and bending when it is squeezed. In other cases, the deformation of the support spring 3 due to extrusion is constrained to improve the stability of the overall structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com