Foam dyeing method capable of achieving non-uniform fashion effect and obtained garment or fabric

A dyeing method, a fashionable technology, applied in partial treatment of fabrics, textiles and papermaking, partial treatment of finished products, etc., can solve the problems of unnatural and natural printing effect, excessive reliance on handwork in tie-dyeing production, etc., and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] The present embodiment provides a foam dyeing method capable of dyeing uneven fashion effects, wherein the method comprises the following specific steps:

[0056] (1) need the ratio of 350g dye liquor according to 1kg ready-made clothes, after reactive dyestuff (ERIOFAST BLUE 3R) is made into dye liquor, place foam generator and carry out foaming treatment to described dye liquor, obtain foaming dye liquor;

[0057] (2) According to the proportion of 500g of hygroscopic washing medium required for 1kg of garments, select hygroscopic washing medium, the edge of the dyeing area is smooth, round cotton balls can be selected, and fine line details can be selected from square cotton, namely cotton blocks;

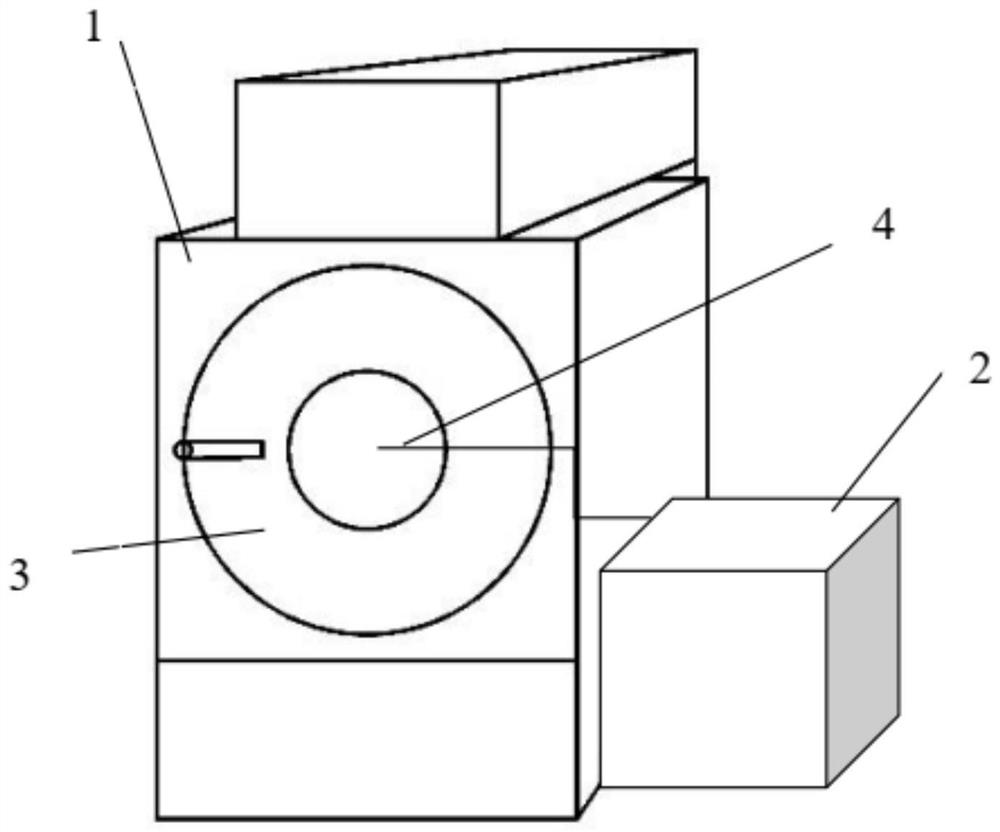

[0058] Put the hygroscopic water-washable medium into the rotatable inner tank of the dyeing equipment, and spray part of the foamed dye liquid to the hygroscopic water-washable medium to fully absorb moisture during the continuous rotation of the inner tank;

[0059] In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com