Patents

Literature

41results about "Article parts treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

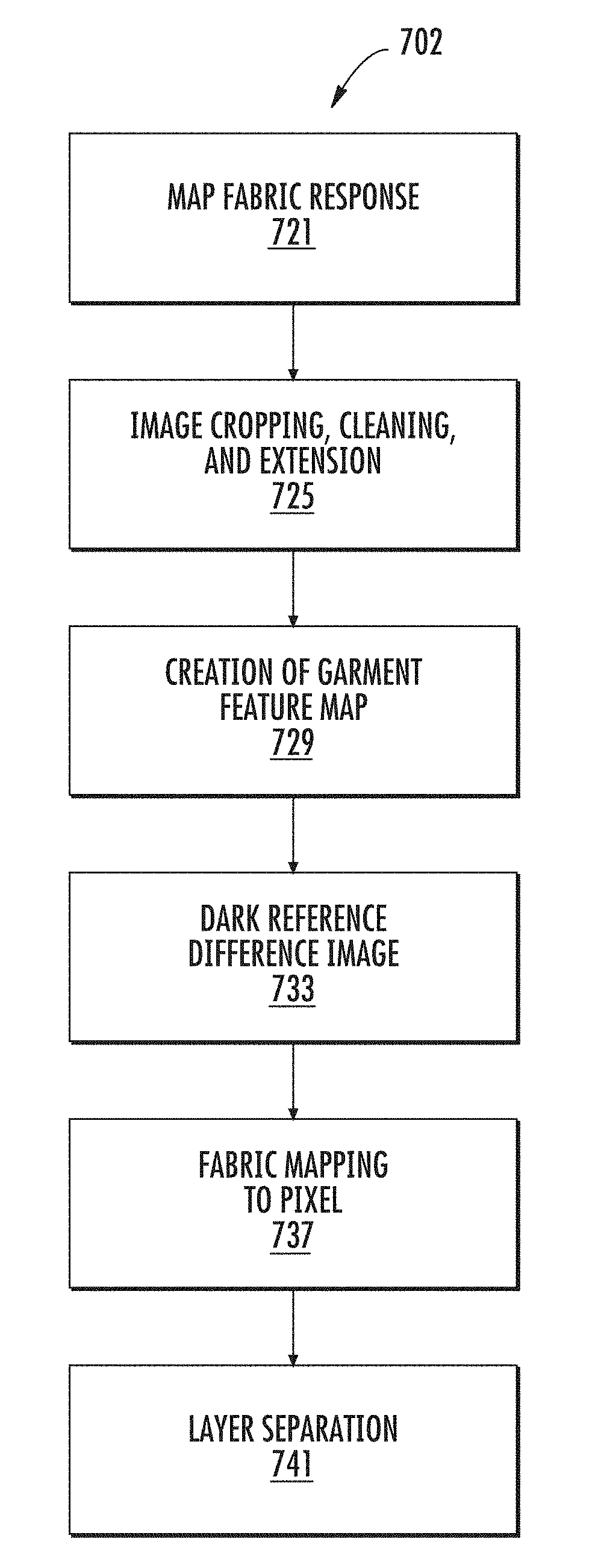

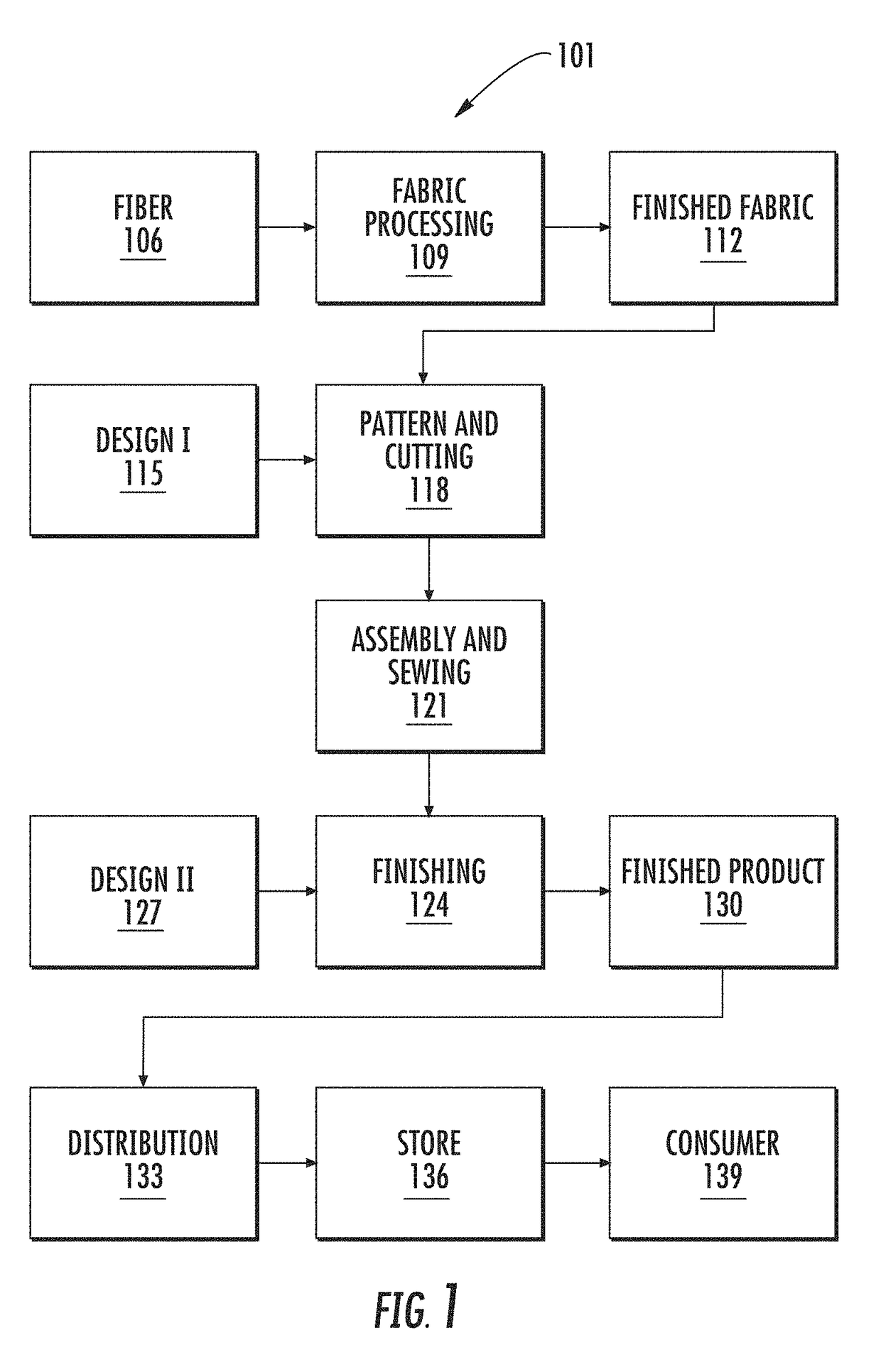

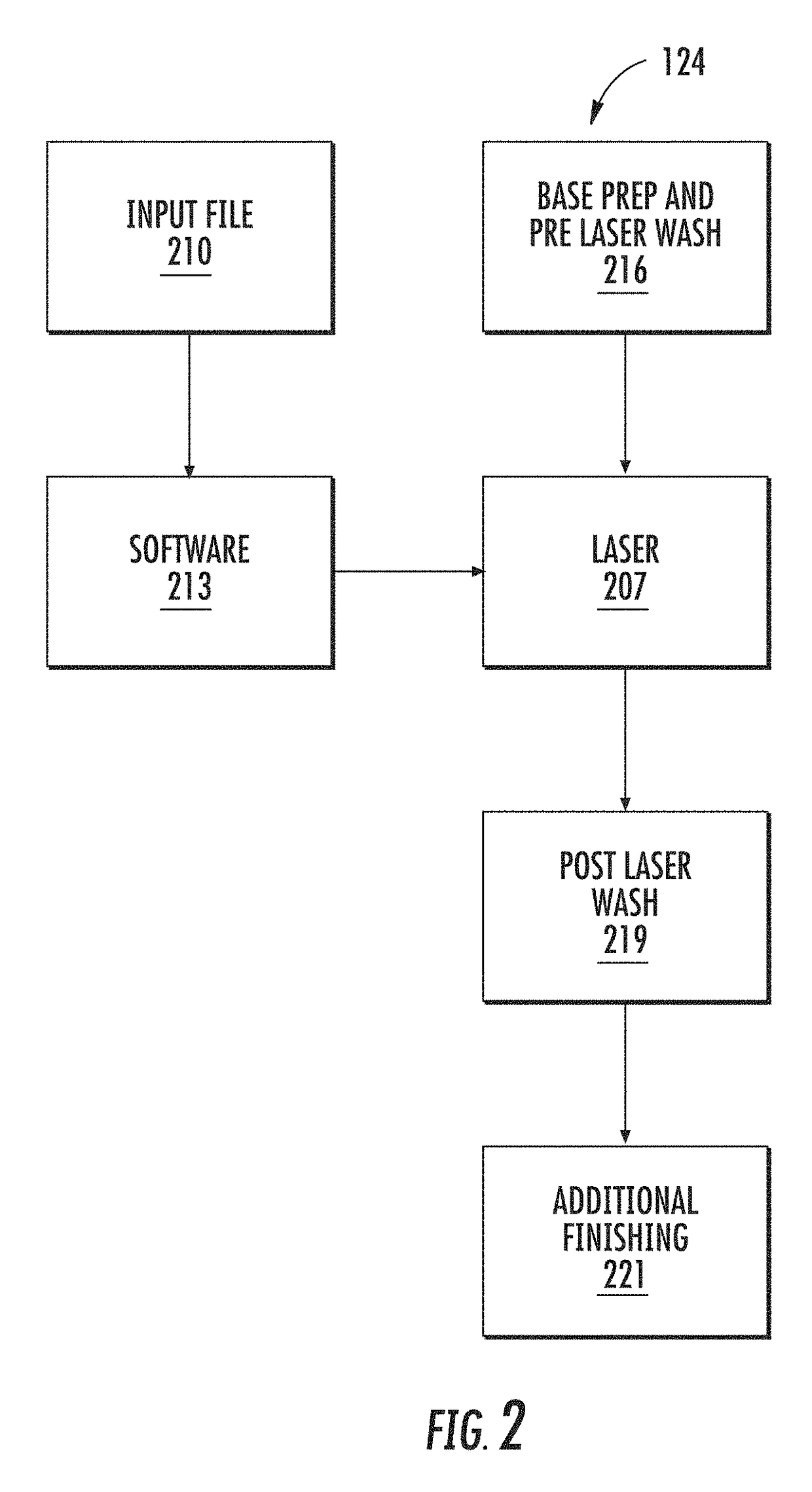

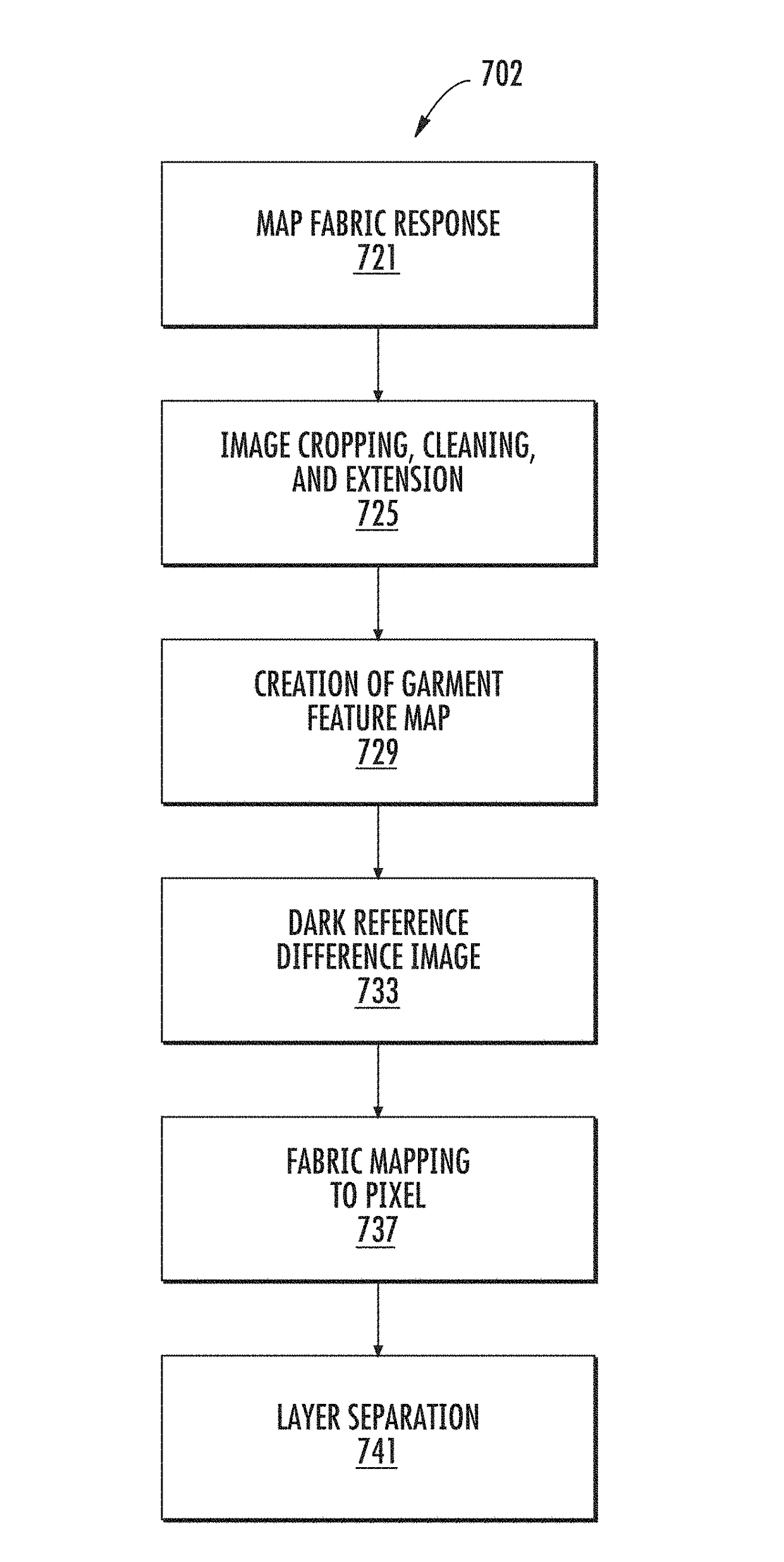

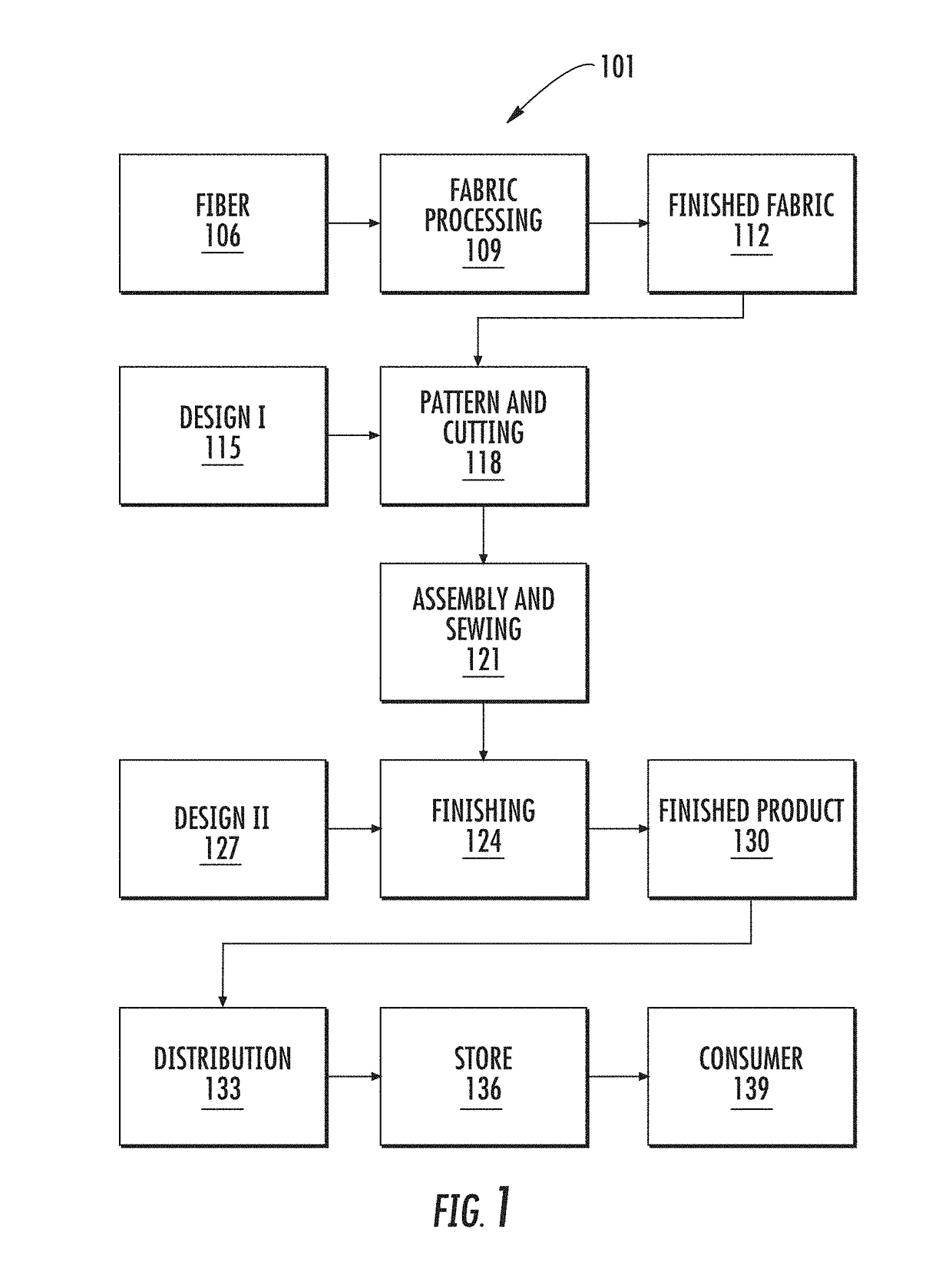

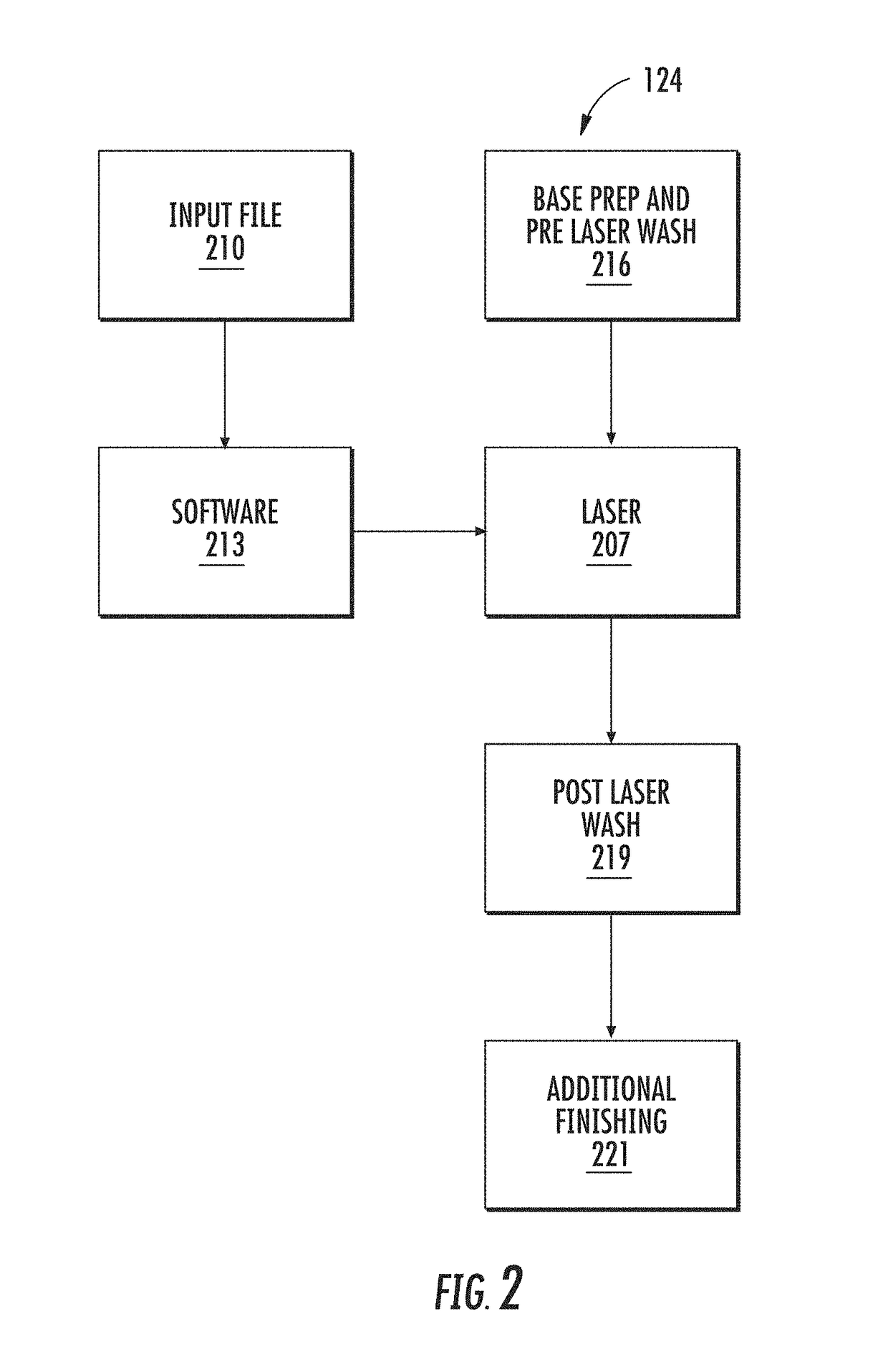

Laser Finishing of Apparel

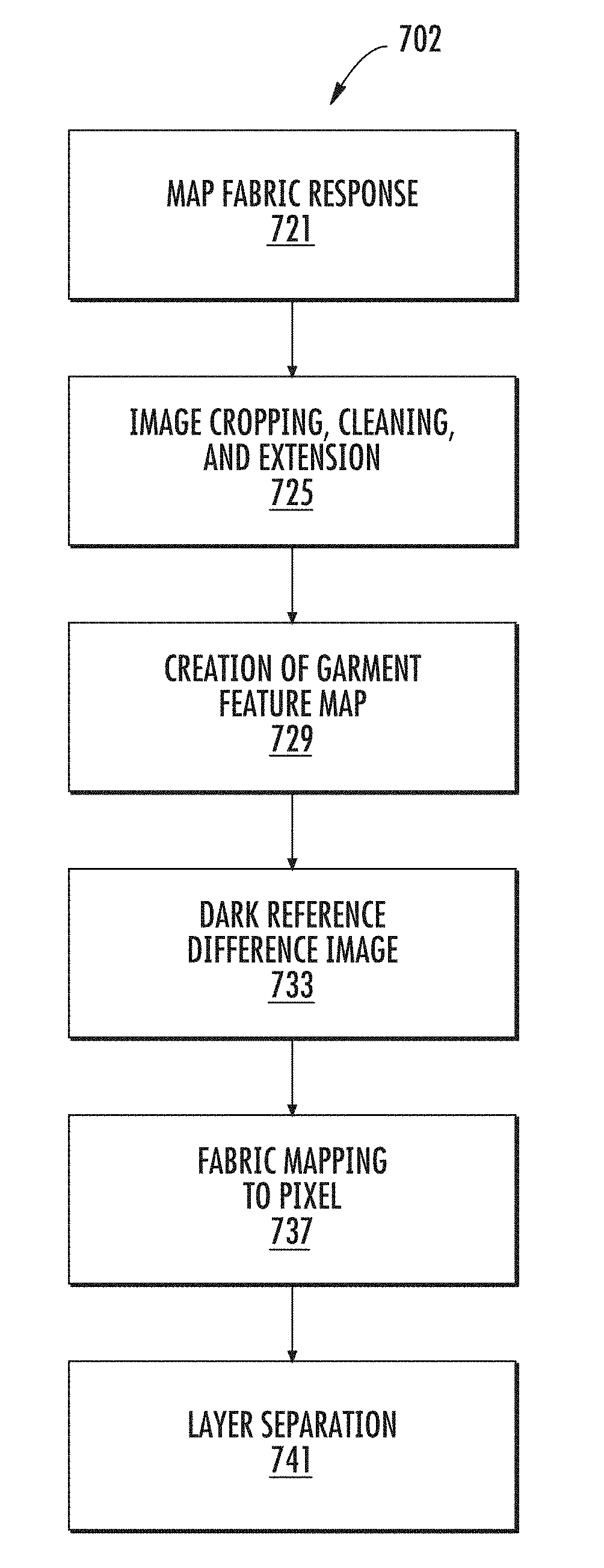

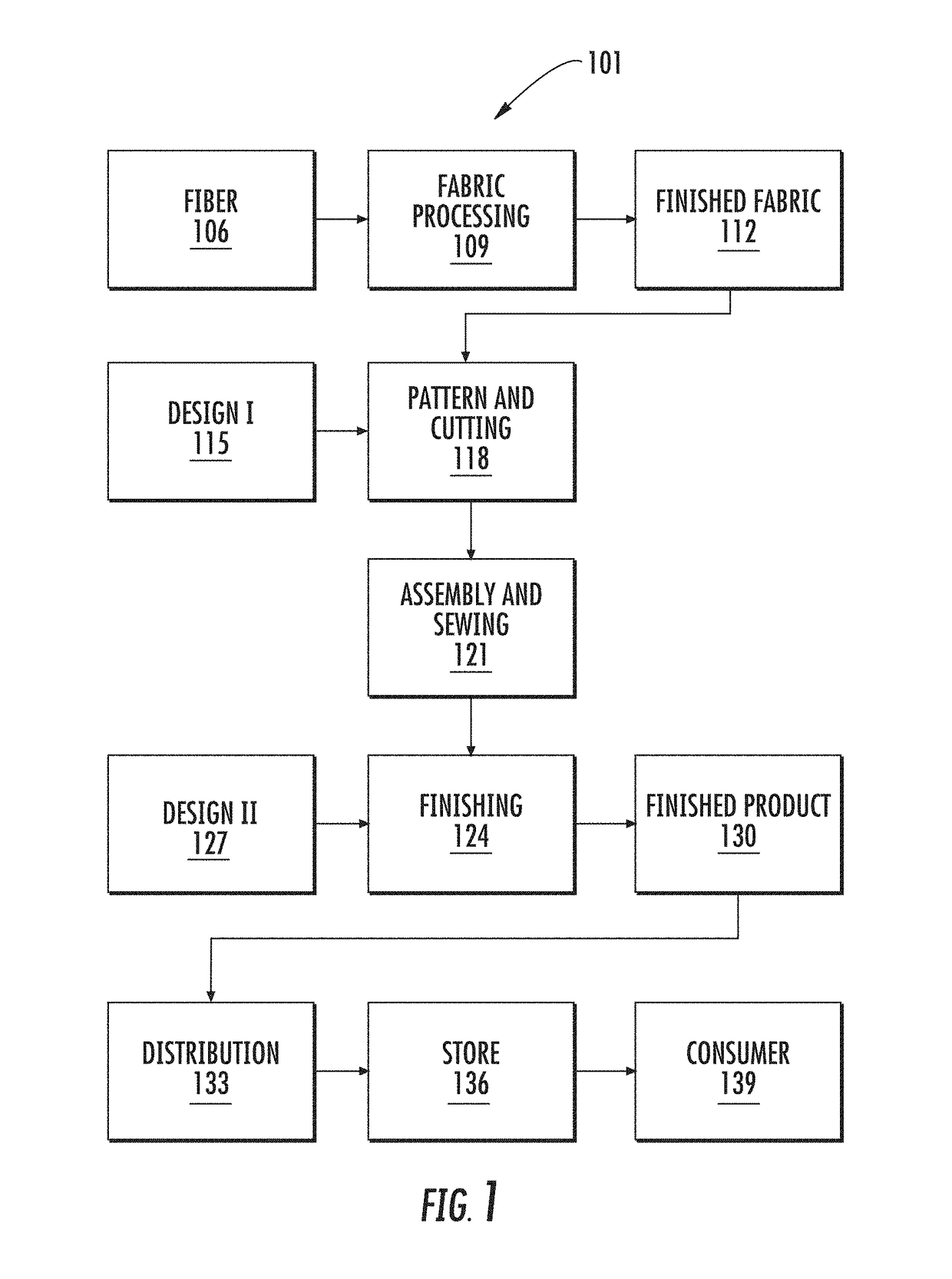

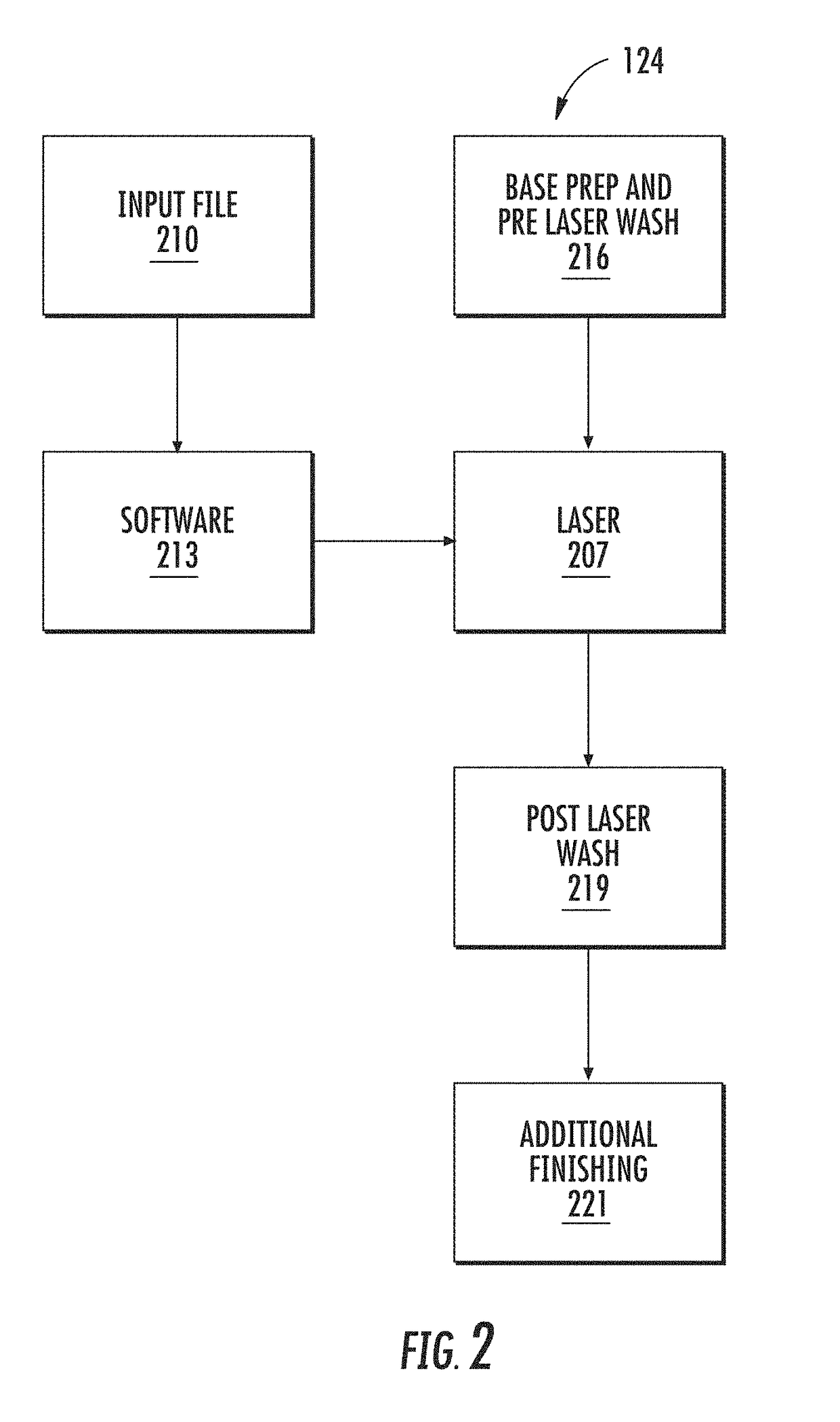

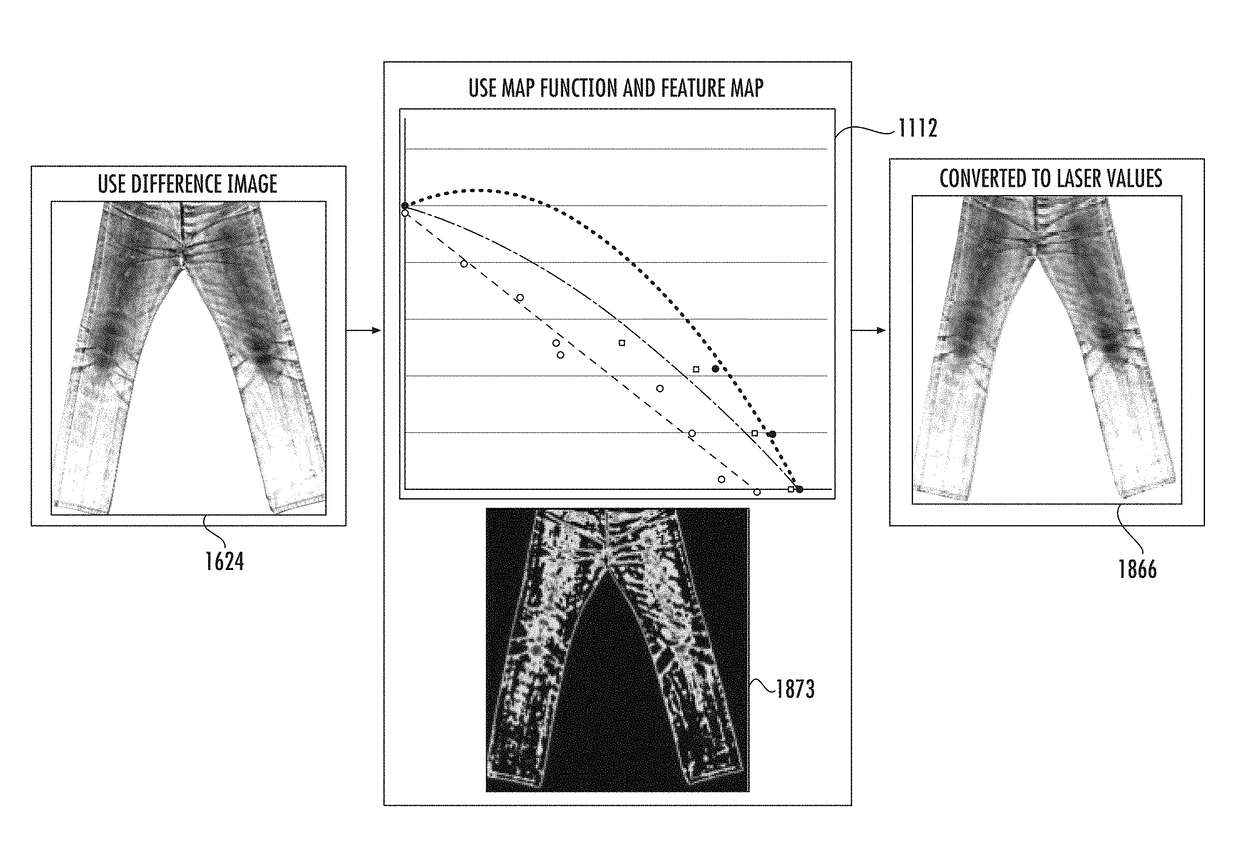

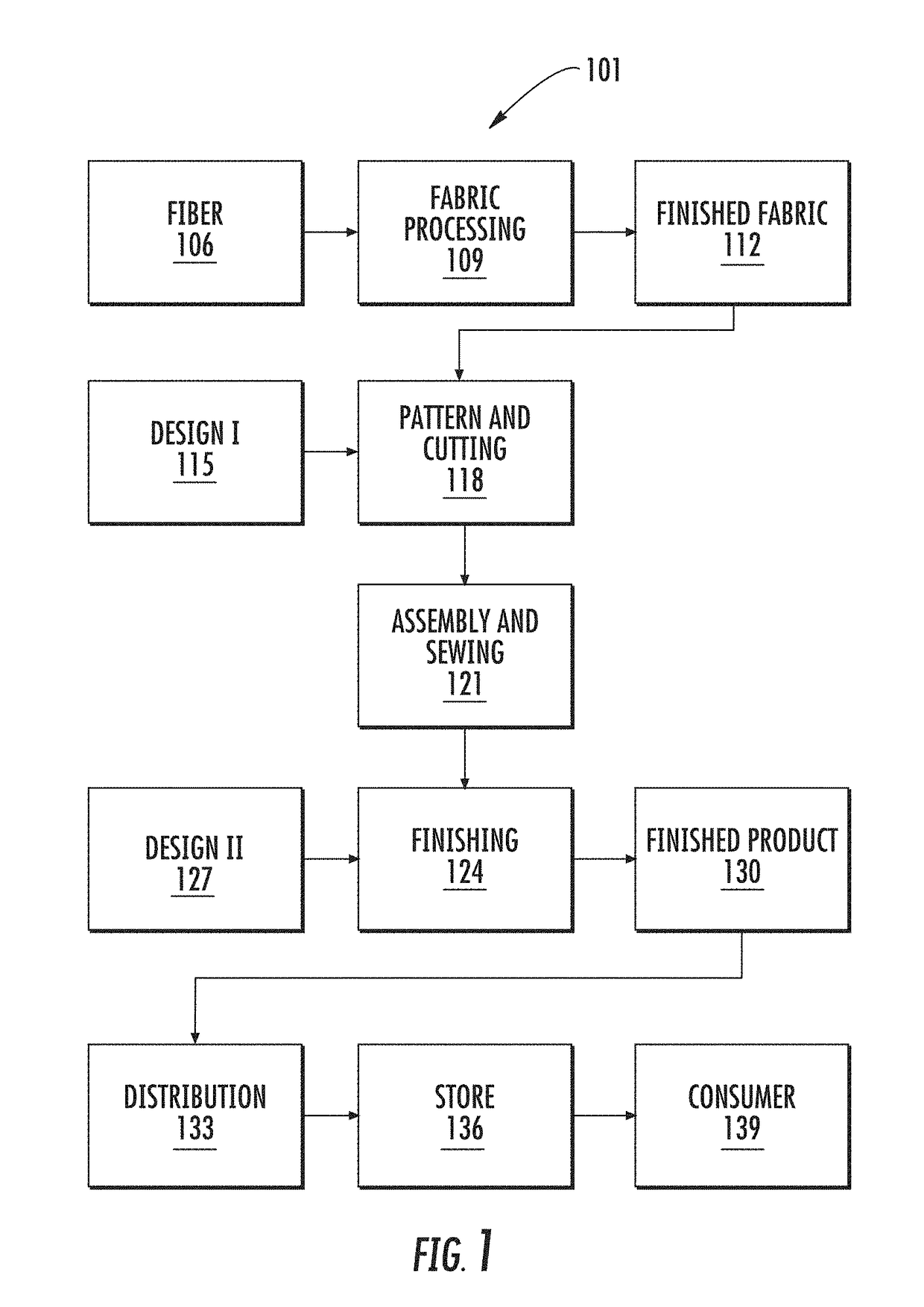

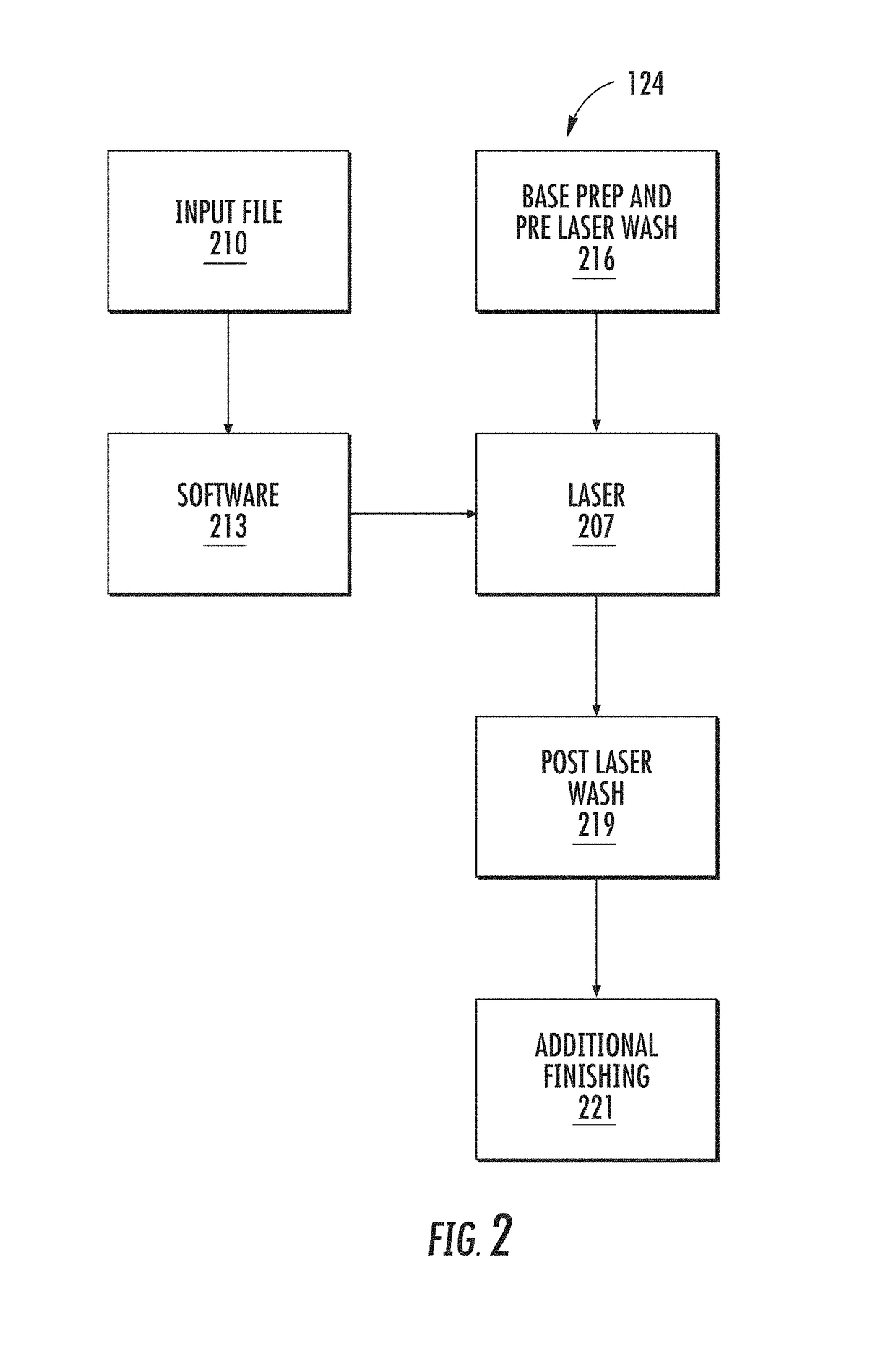

Software and lasers are used in finishing apparel to produce a desired wear pattern or other design. A technique includes determining a fabric's response to a laser, capturing an initial image of a wear pattern on a garment, and processing the initial image to obtain a working image in grayscale. The working image is further processed to obtain a difference image by comparing each pixel relative to a dark reference. The difference image is converted to a laser values image by using the previously determined fabric response to the laser.

Owner:LEVI STRAUSS & CO

Laser finishing of apparel

Software and lasers are used in finishing apparel to produce a desired wear pattern or other design. A technique includes determining a fabric's response to a laser, capturing an initial image of a wear pattern on a garment, and processing the initial image to obtain a working image in grayscale. The working image is further processed to obtain a difference image by comparing each pixel relative to a dark reference. The difference image is converted to a laser values image by using the previously determined fabric response to the laser.

Owner:LEVI STRAUSS & CO

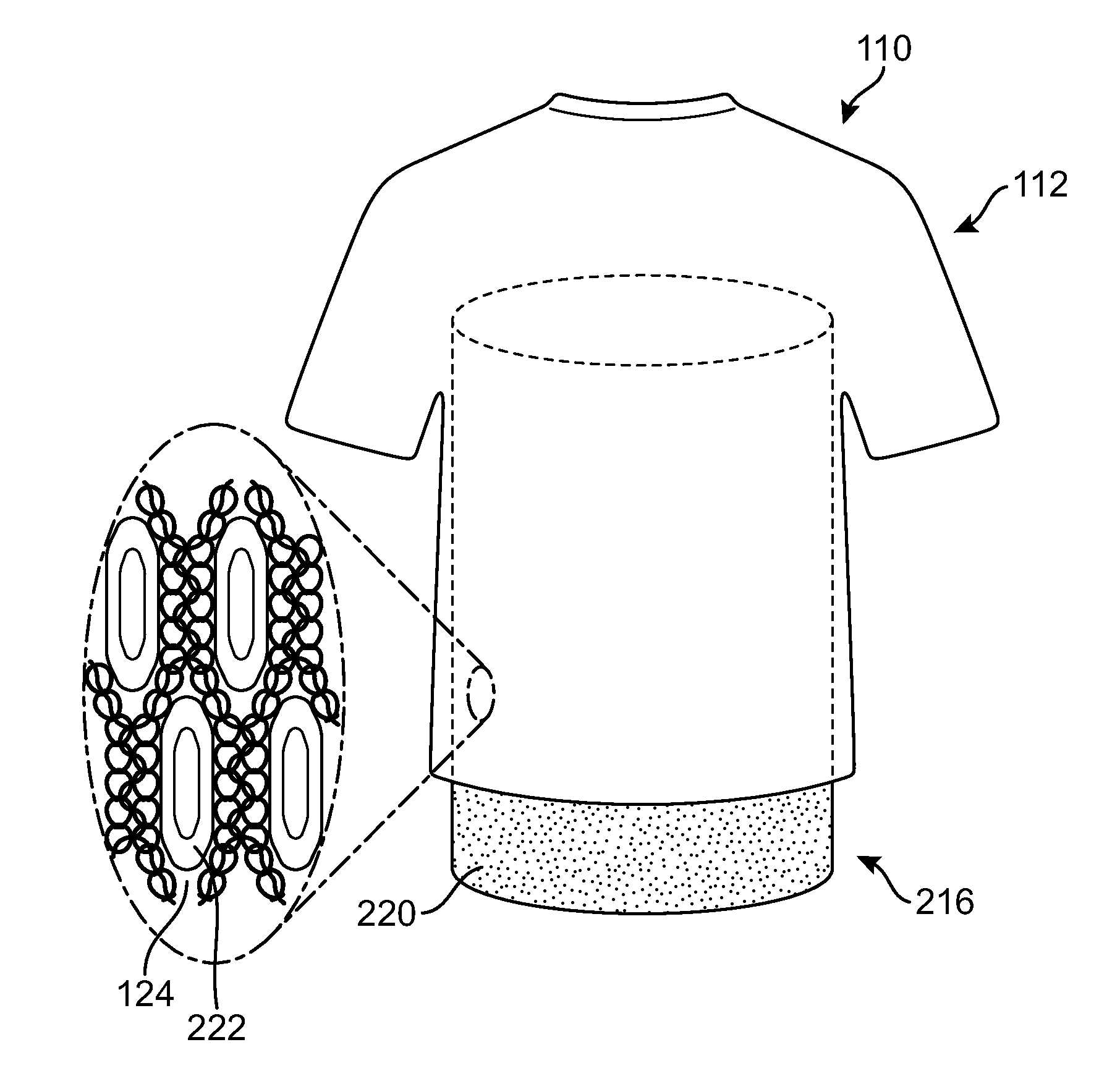

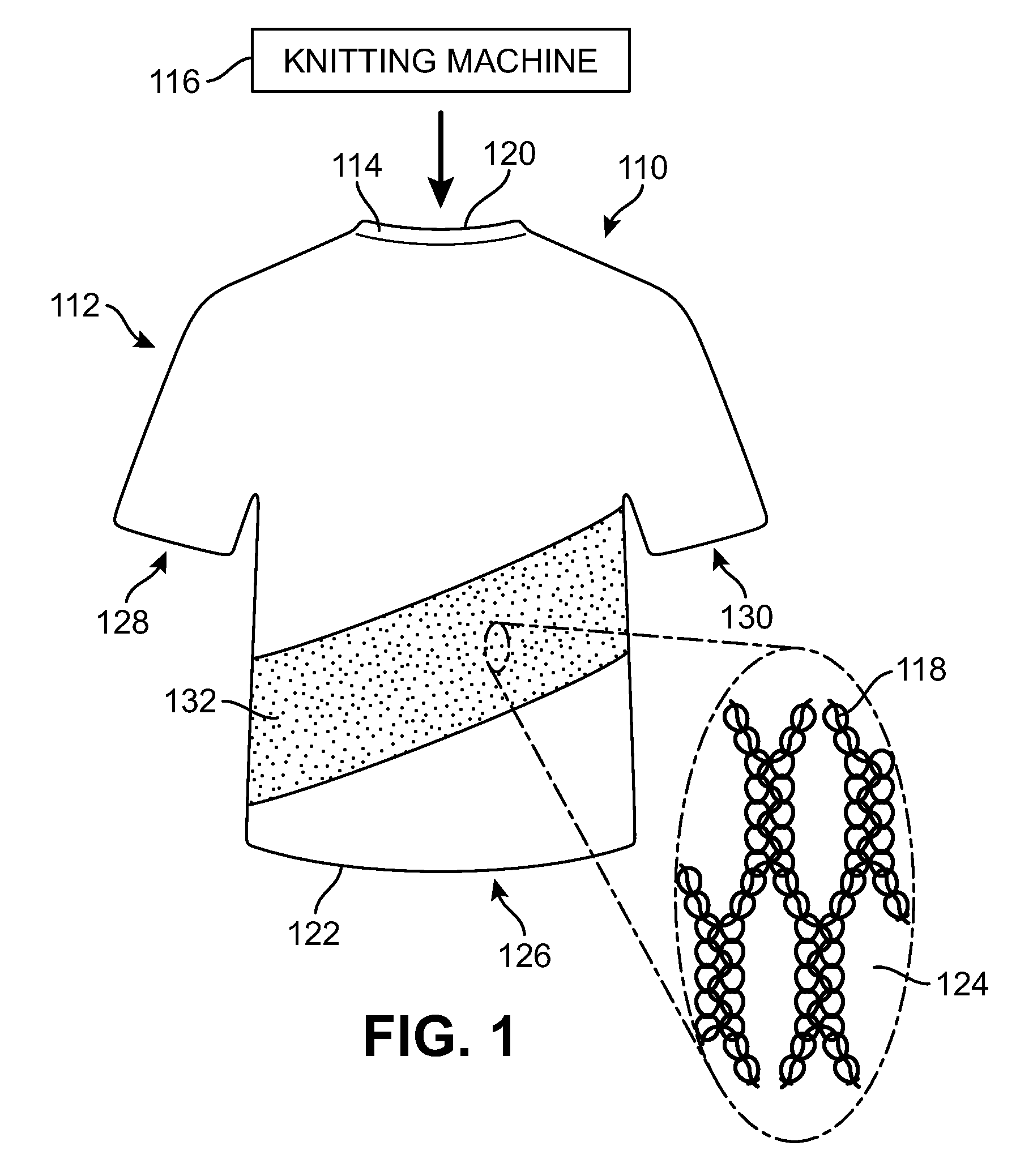

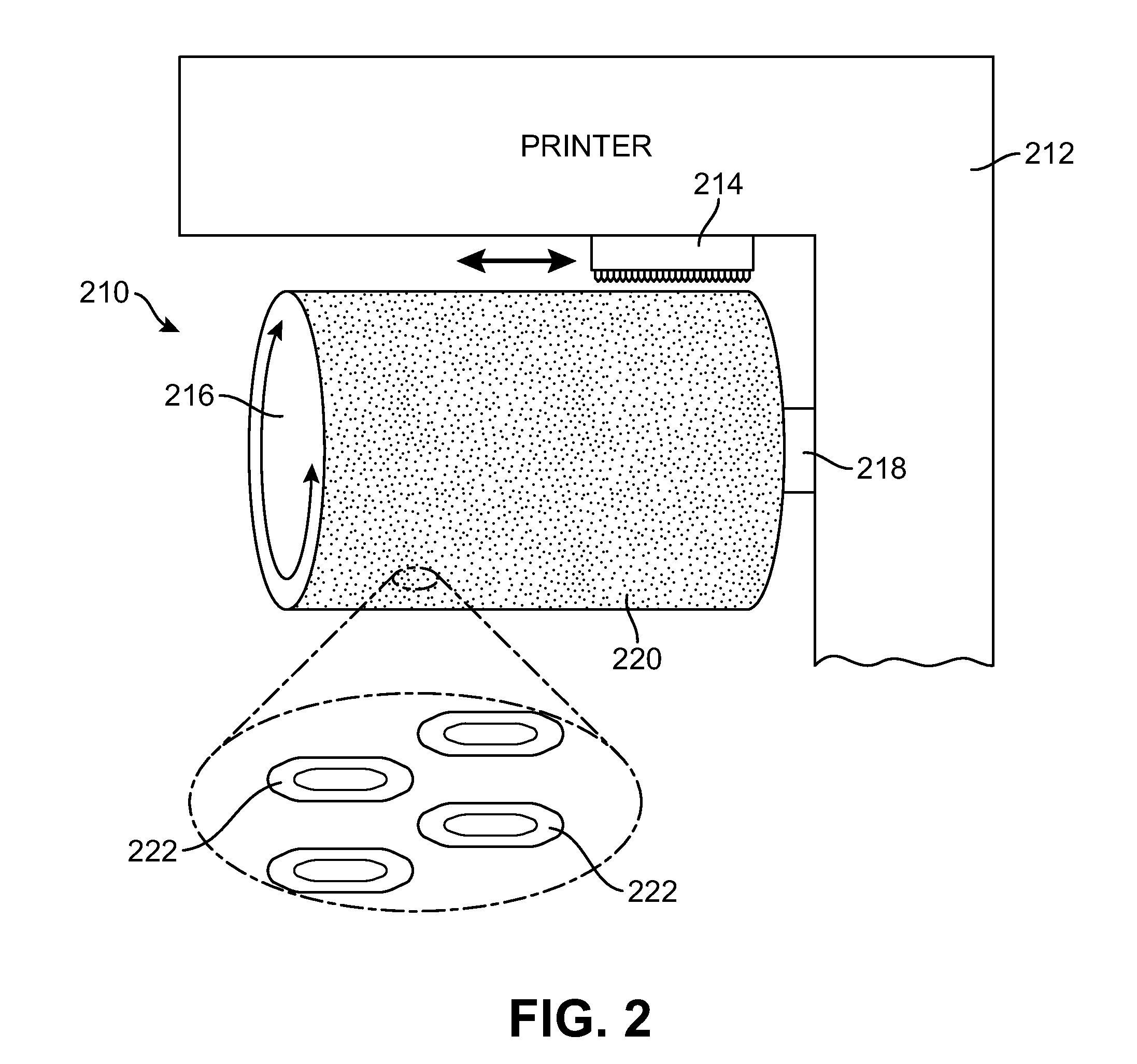

Knit article of apparel and apparel printing system and method

An article of apparel including a tubular knit textile region is provided, as well as an apparel printing system for printing on regions of the tubular knit textile region and related methods. The article of apparel can include a tubular knit textile region having an internal side and an opposite external side configured to be exposed during use, a plurality of yarns in an arrangement of interlocked loops forming parallel rows and channels therebetween, and a printed ink design on its external side. The printed ink design can be formed from ink applied to the parallel rows of loops and to the channels. An apparel printing system for printing on the article of apparel can include a textile printer having a print head and a tubular platen that includes features on the platen surface to retain and register the tubular knit textile on the platen surface during printing.

Owner:NIKE INC

Using Laser to Create Finishing Pattern on Apparel

Software and lasers are used in finishing apparel to produce a desired wear pattern or other design. A technique includes determining a fabric's response to a laser, capturing an initial image of a wear pattern on a garment, and processing the initial image to obtain a working image in grayscale. The working image is further processed to obtain a difference image by comparing each pixel relative to a dark reference. The difference image is converted to a laser values image by using the previously determined fabric response to the laser.

Owner:LEVI STRAUSS & CO

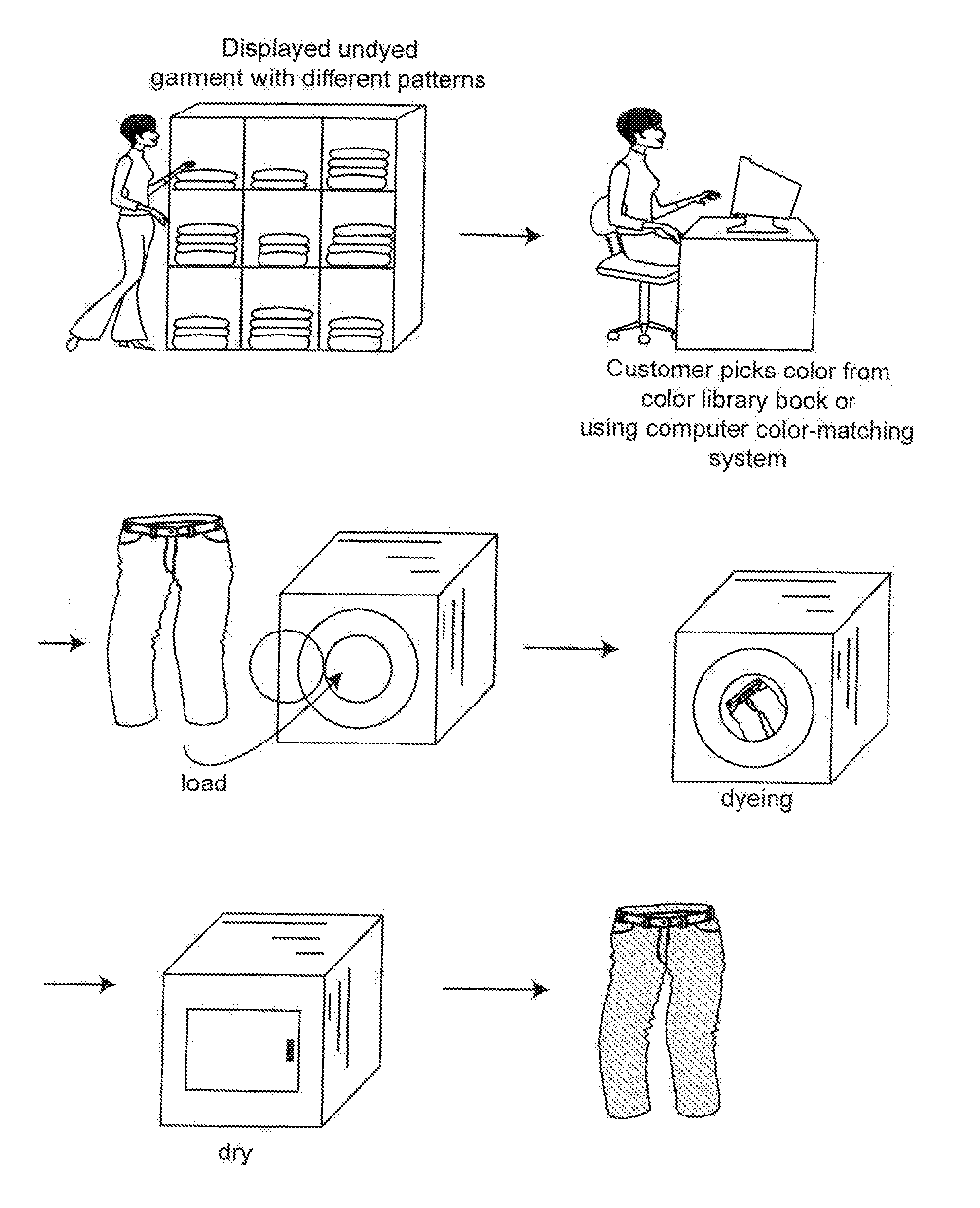

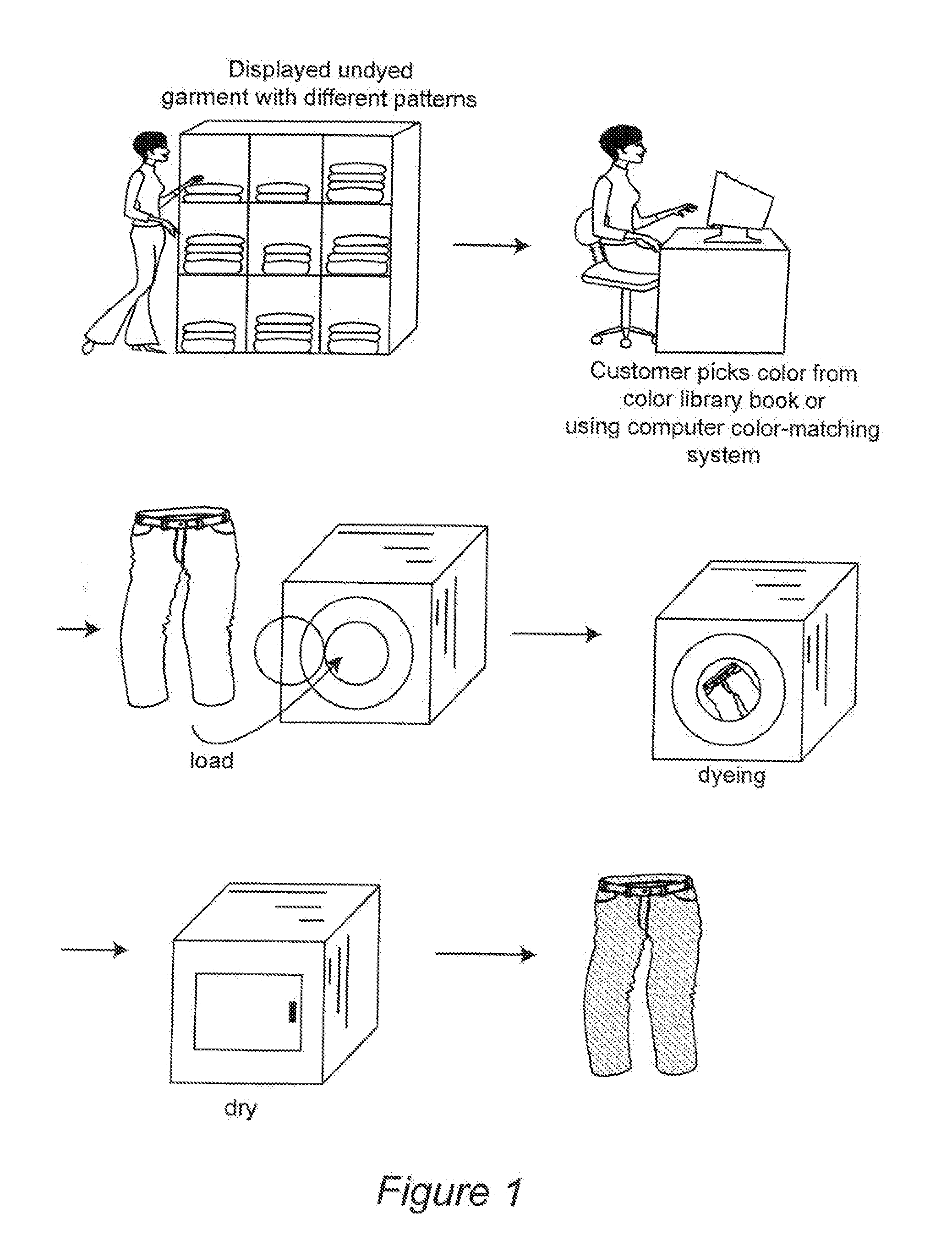

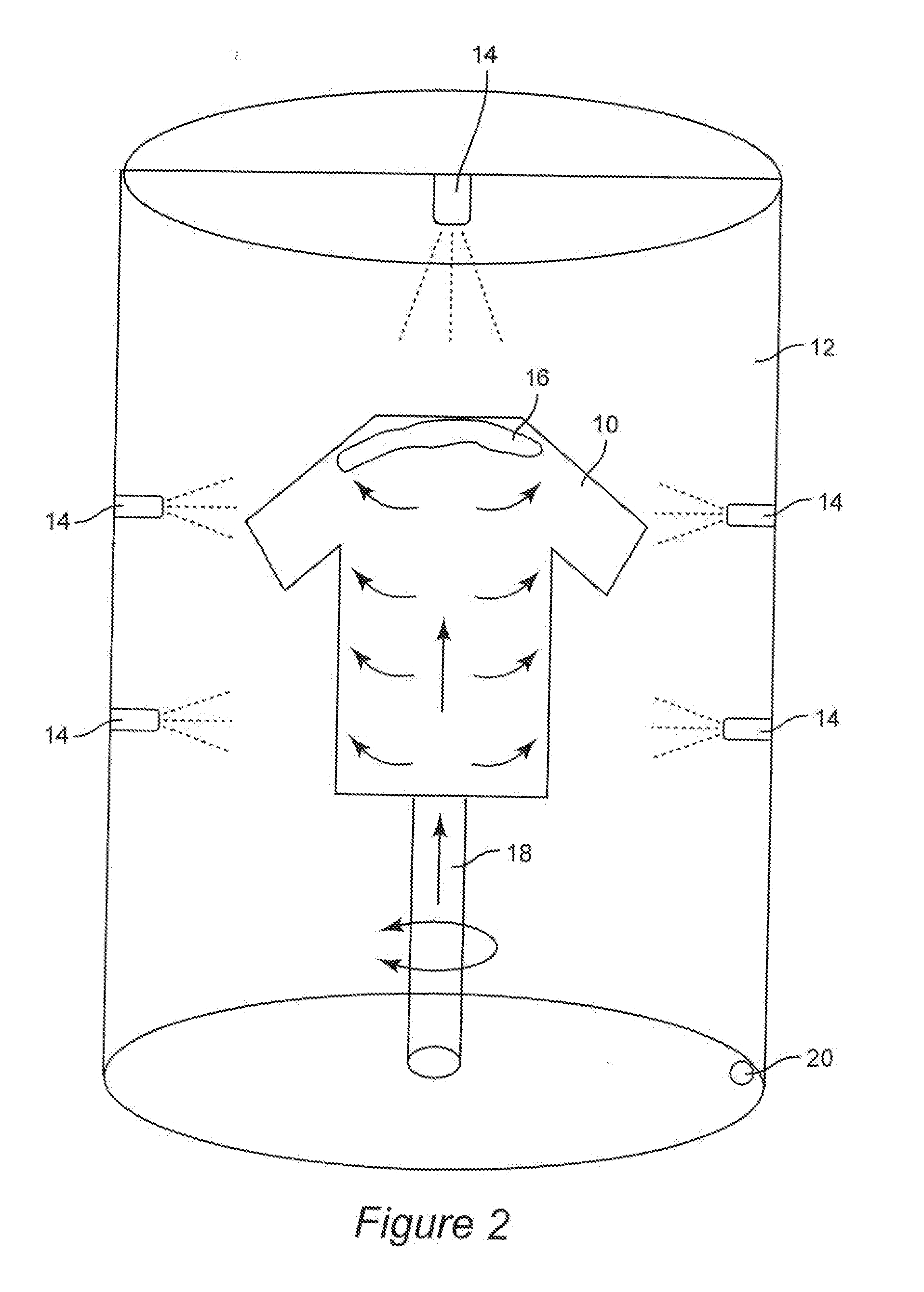

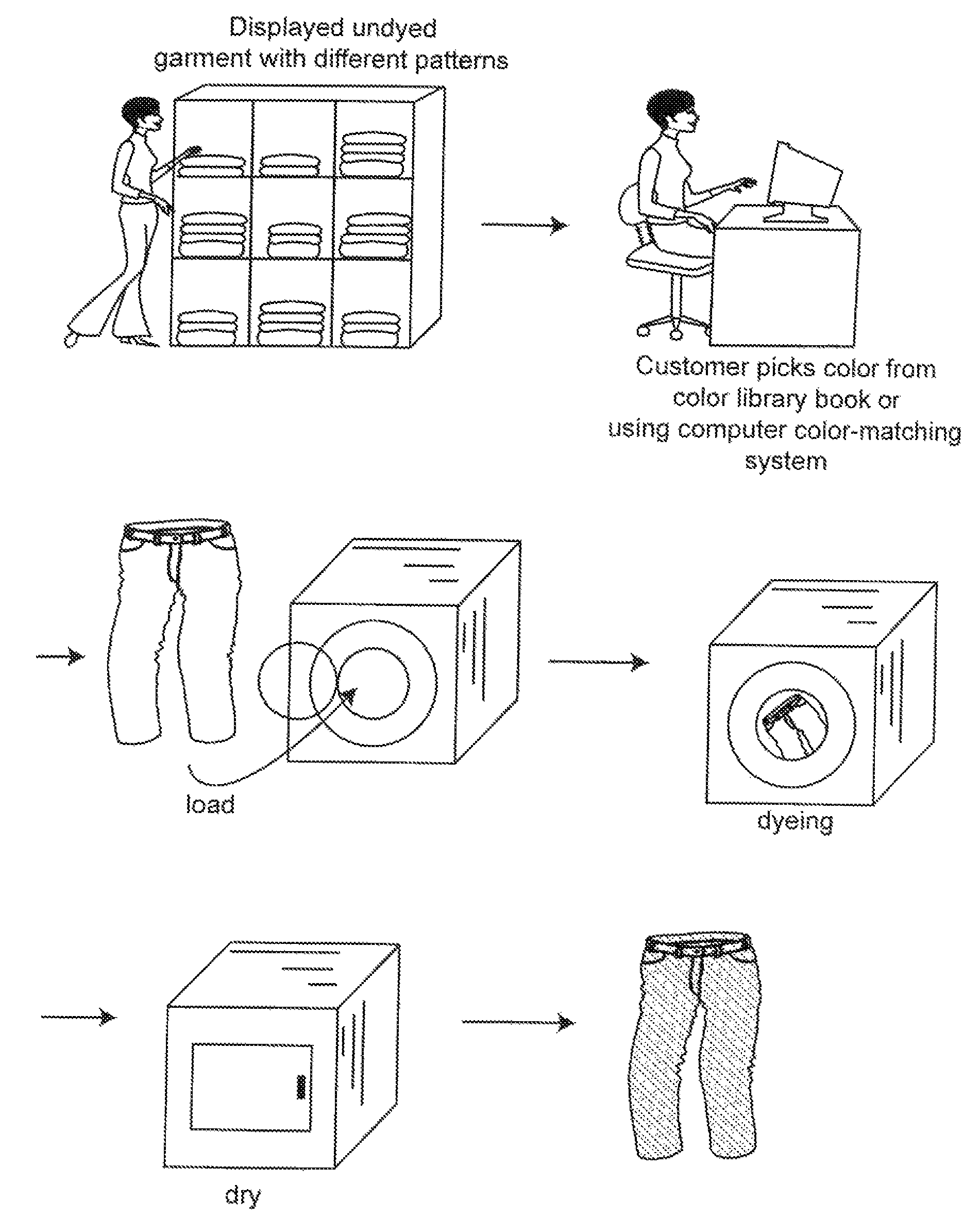

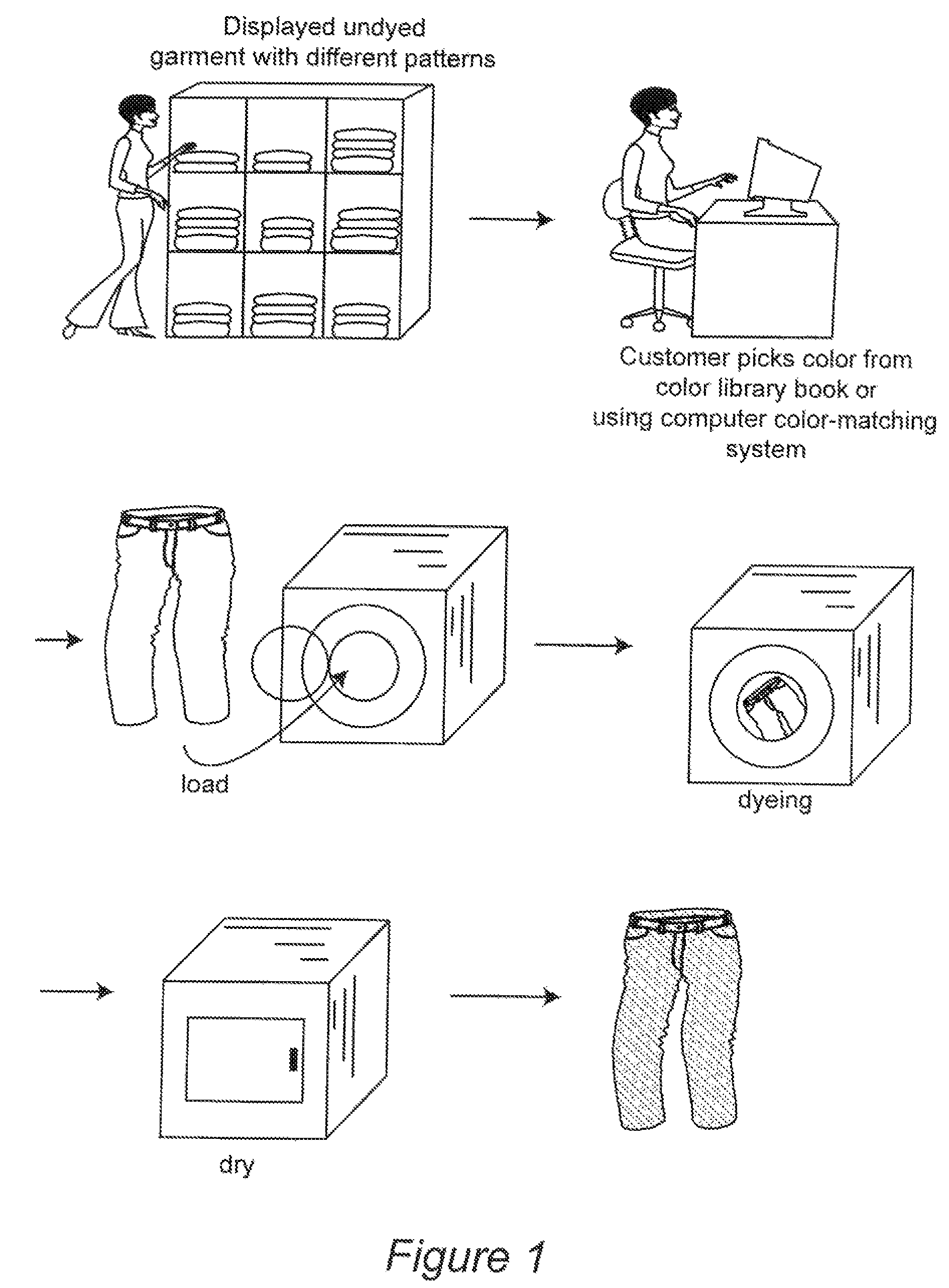

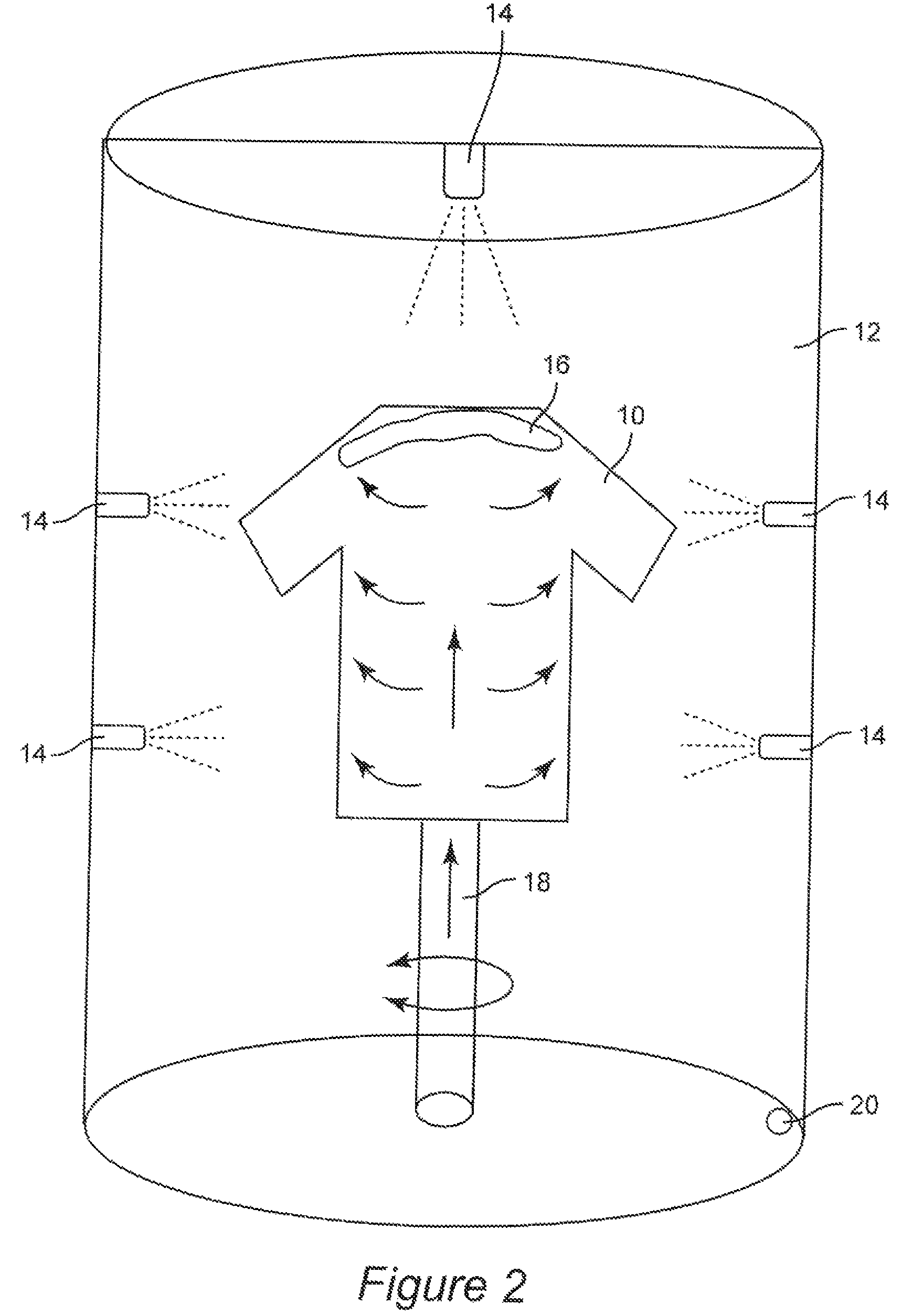

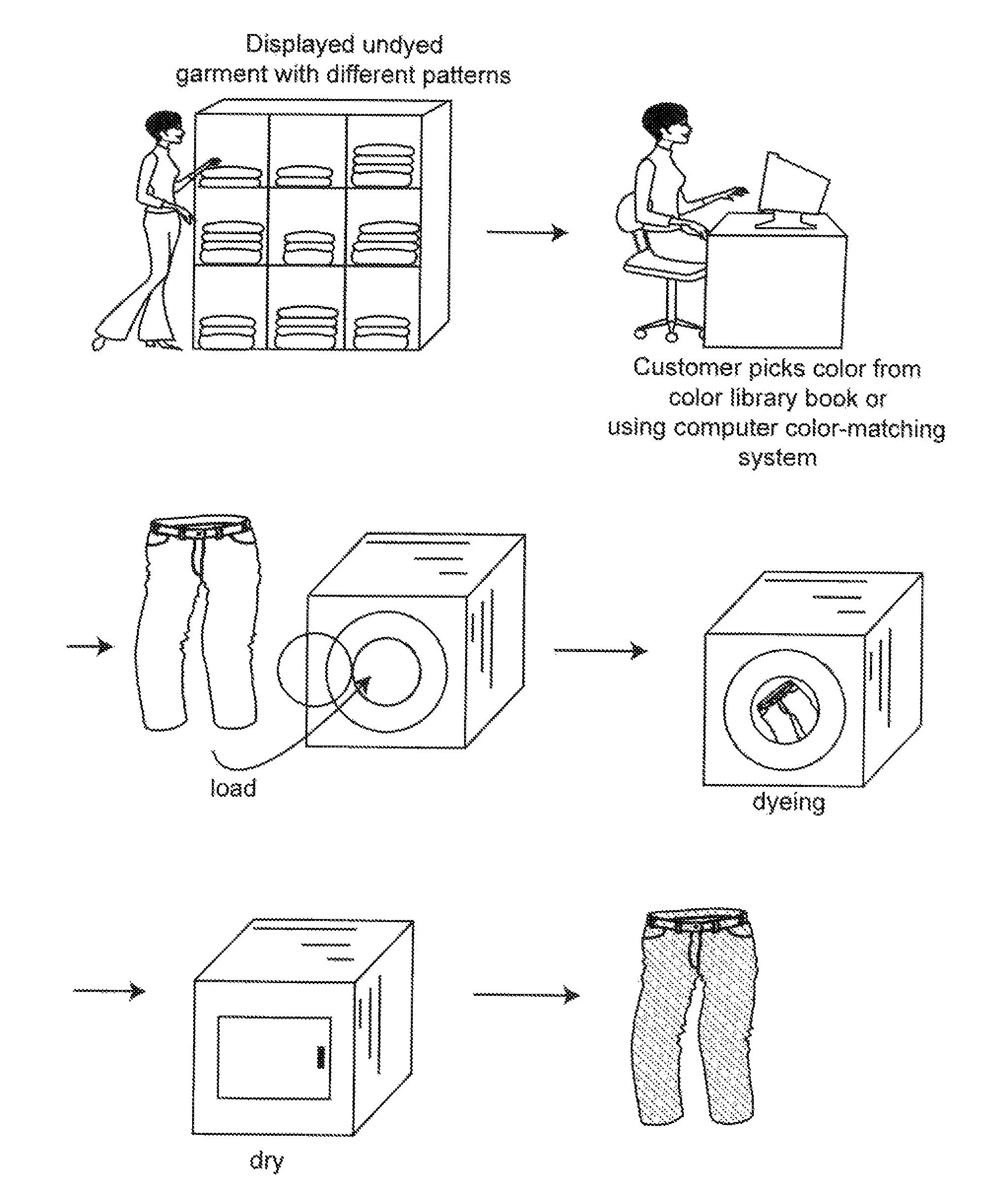

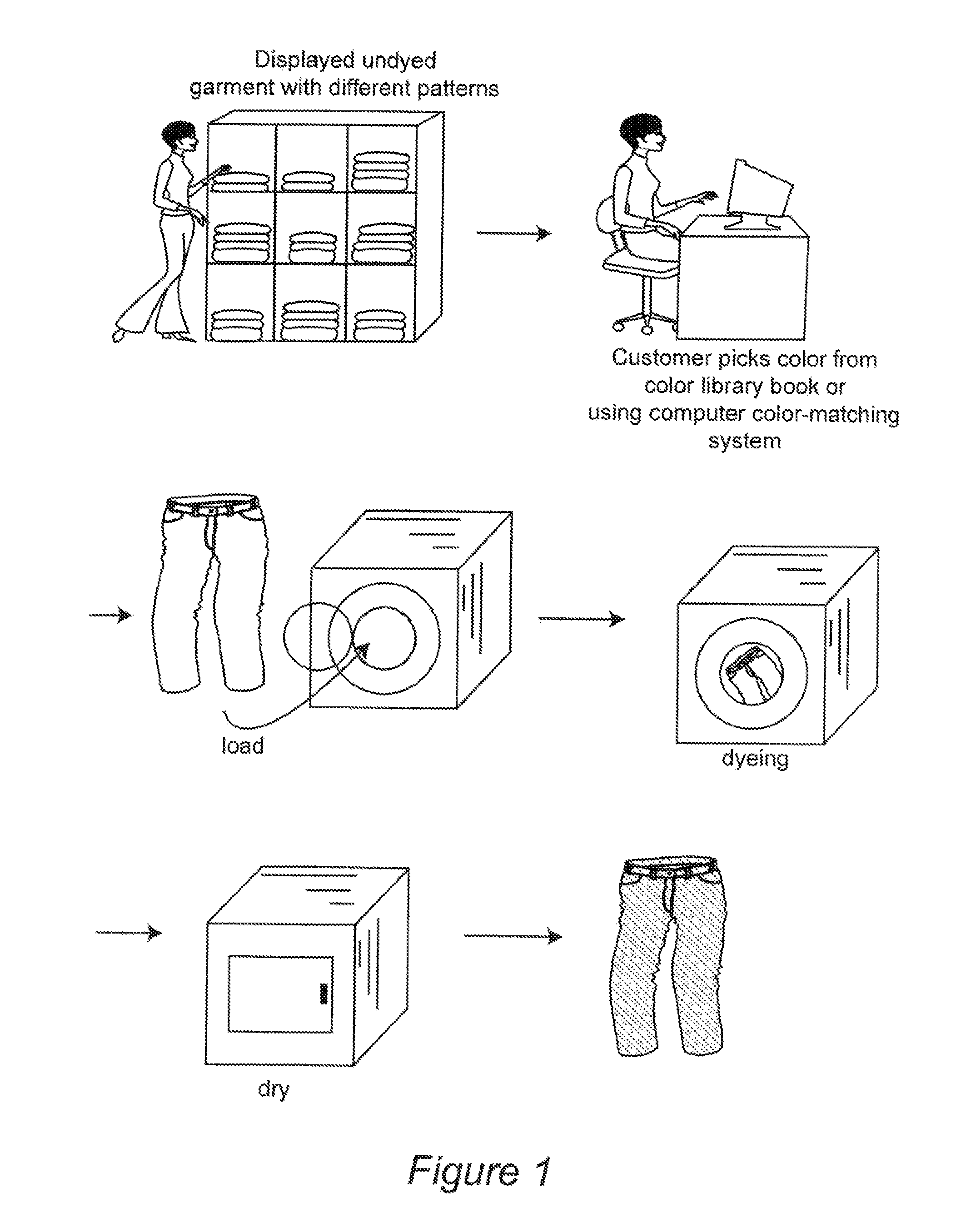

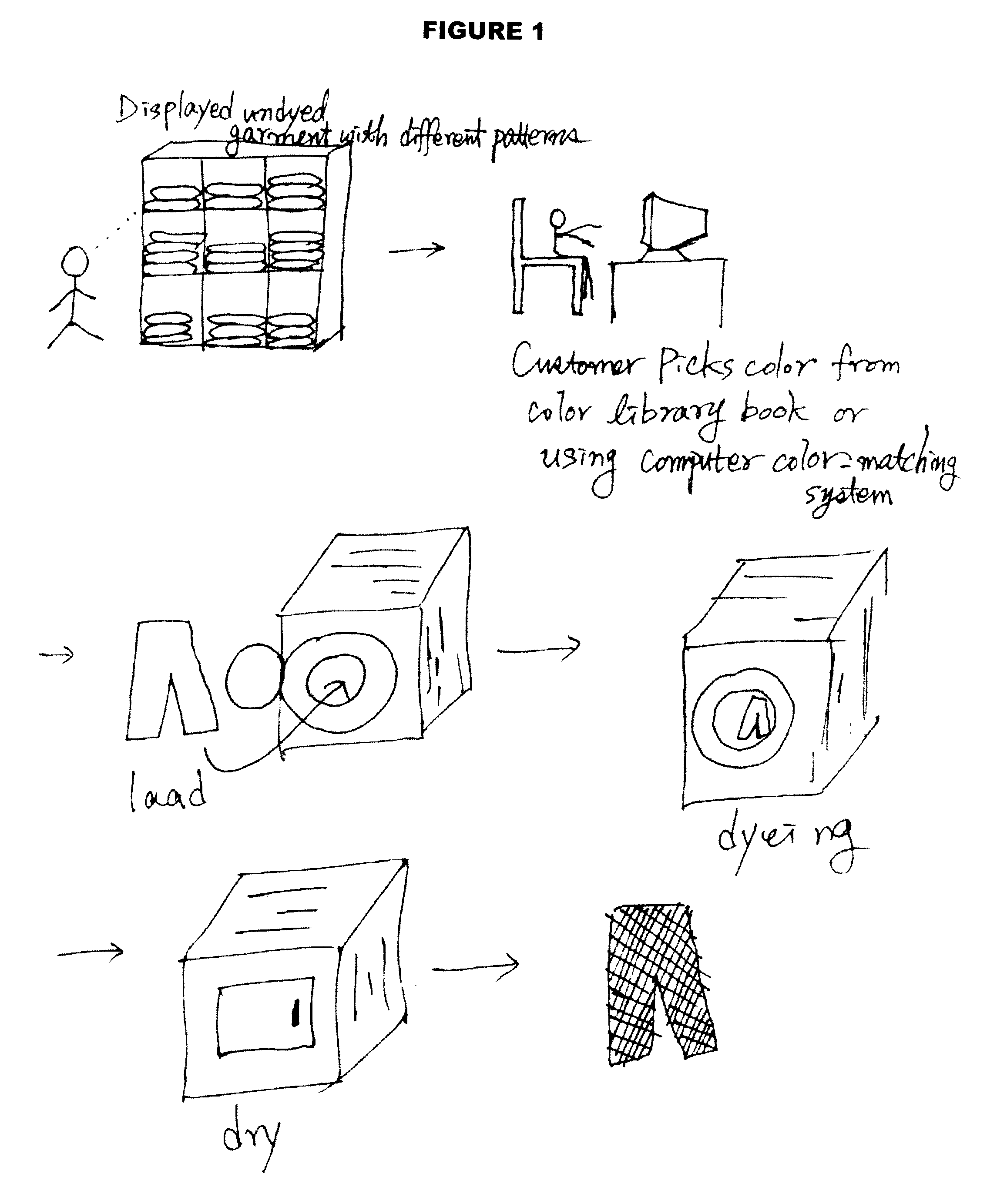

Customer-Created Textiles and Customer-Oriented Garment Dyeing Machine

ActiveUS20110016019A1Enhance educational experienceImprove entertainment experienceTextile treatment containersLiquid/gas/vapor article treatmentYarnEngineering

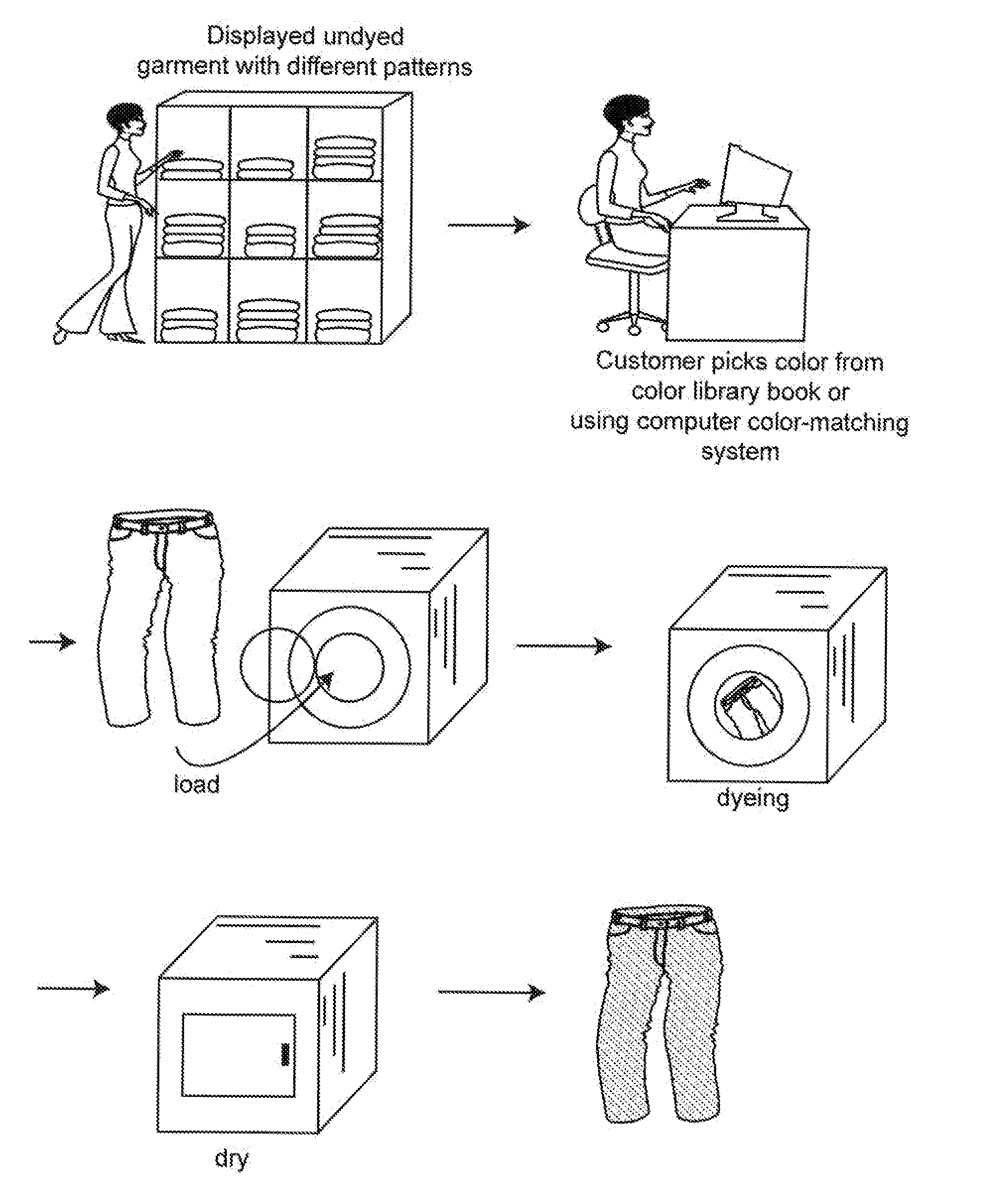

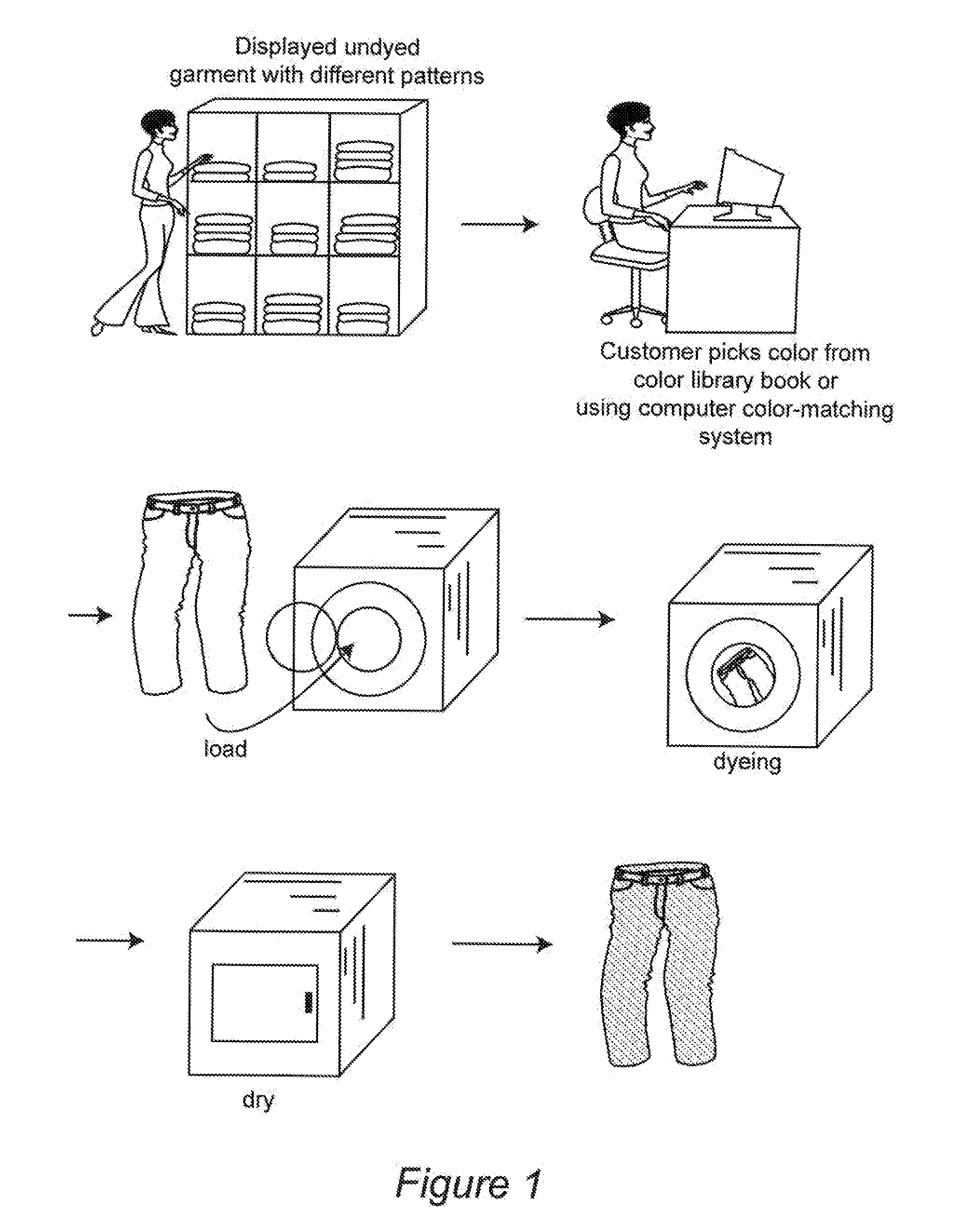

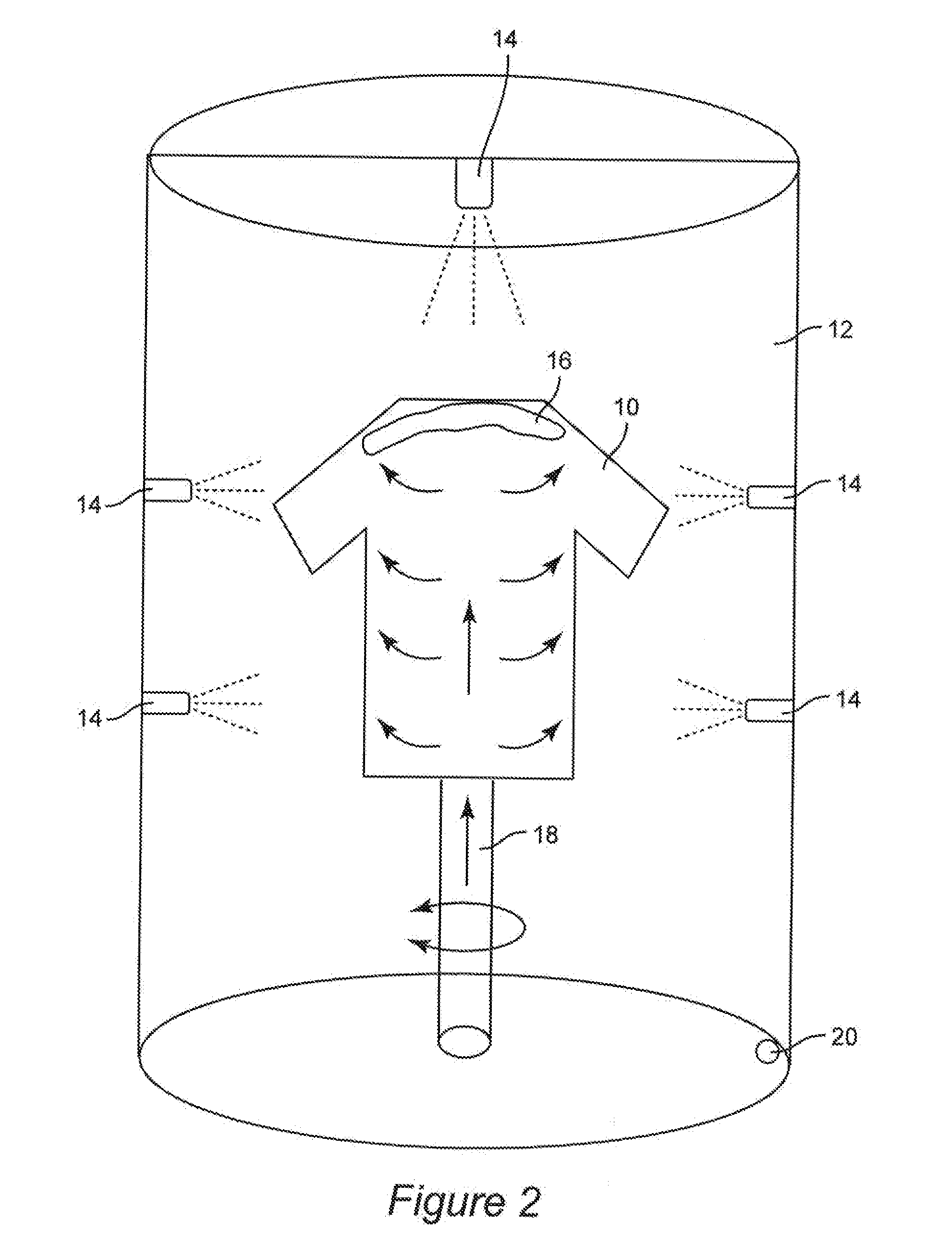

Customers obtain customized textile materials by selecting style, shape, size, pattern and color for an undyed textile product. Based on a selection made by the customer, the textile product is transformed by a dyeing operation performed on a single item (or multiple items selected to be dyed the same) to yield a product, such as a shirt, pants, or jacket, which has a color and pattern of his or her own choosing, in the size and style he or she desires. The process can be performed in a retail setting using a dye apparatus which allows the process to be viewed by the customer. Preferably, the textile material is constructed from yarns which include cationic cellulosic fiber alone or in combination with natural or synthetic fibers, and using anionic dyes, such as a fiber reactive dye, such that the dye is exhausted during the process and effluent from the dye machine is environmentally friendly without excess dye, salts, and alkalis. To enhance the educational and entertainment experience of the customer, the dyeing operation can be performed in a transparent tank or water kettle in the retail outlet so that the customer can view, for example, the garment as it is being dyed to the customer's specifications.

Owner:TINTORIA PIANA US

Laser Finishing System for Apparel

Software and lasers are used in finishing apparel to produce a desired wear pattern or other design. A technique includes determining a fabric's response to a laser, capturing an initial image of a wear pattern on a garment, and processing the initial image to obtain a working image in grayscale. The working image is further processed to obtain a difference image by comparing each pixel relative to a dark reference. The difference image is converted to a laser values image by using the previously determined fabric response to the laser.

Owner:LEVI STRAUSS & CO

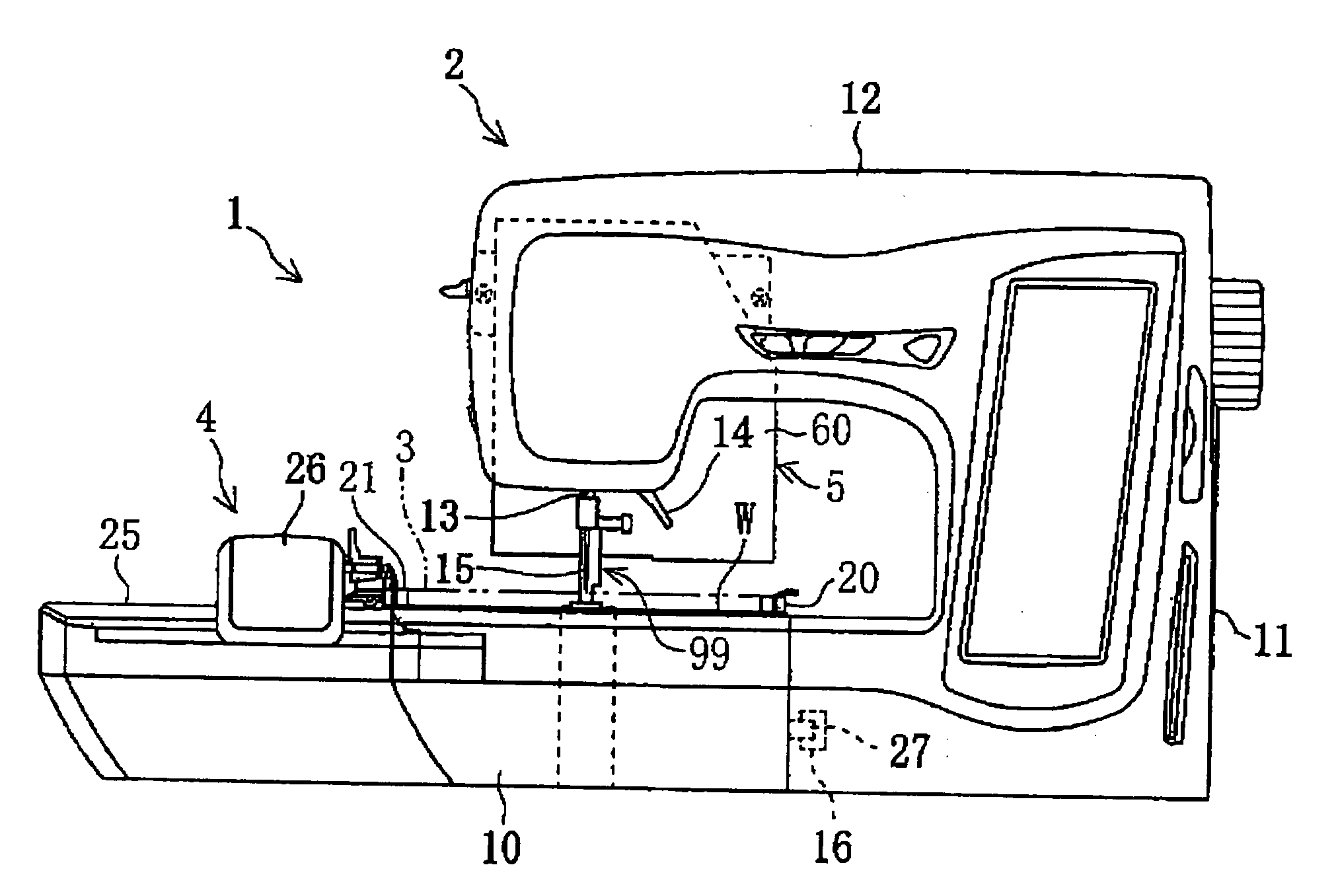

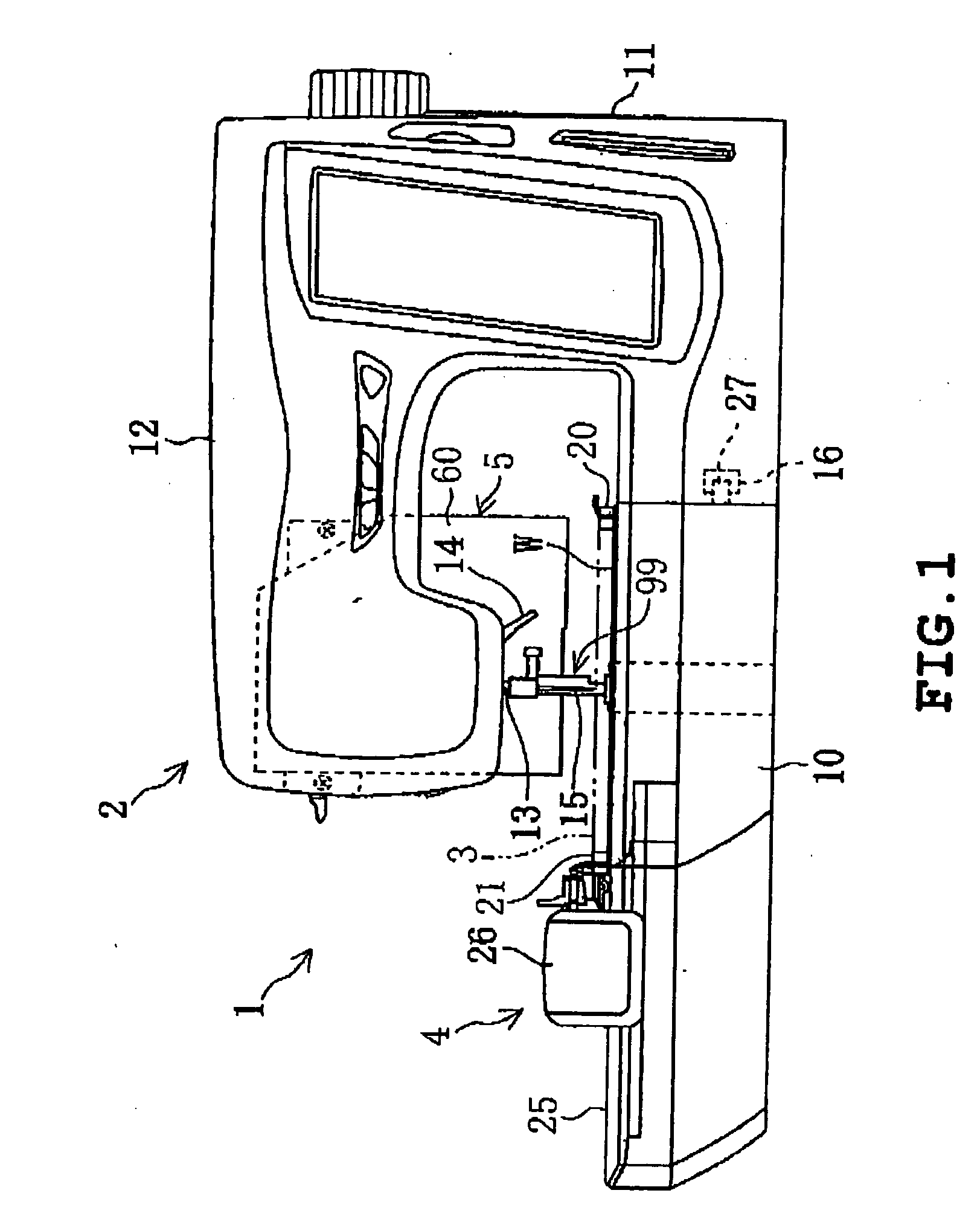

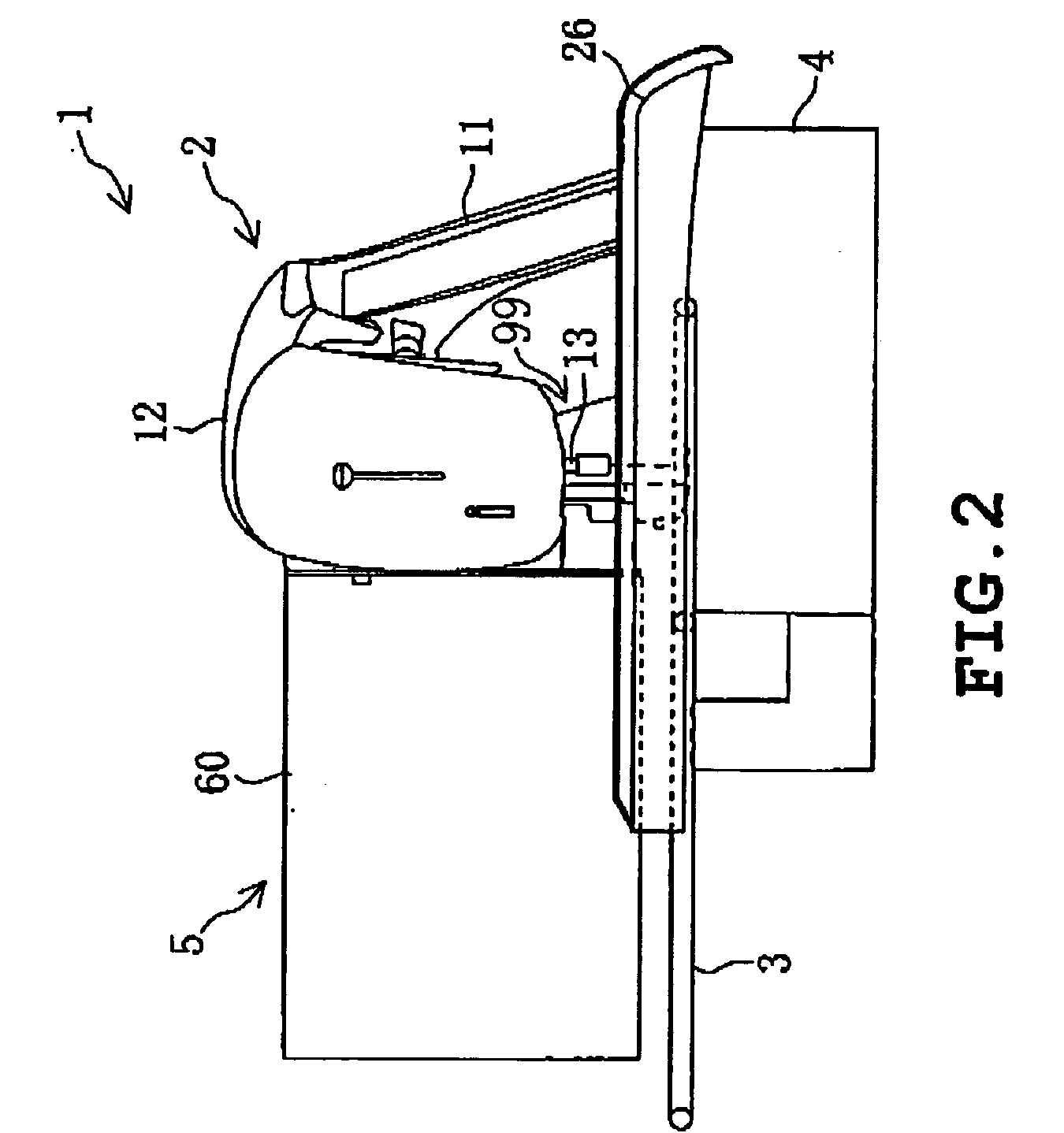

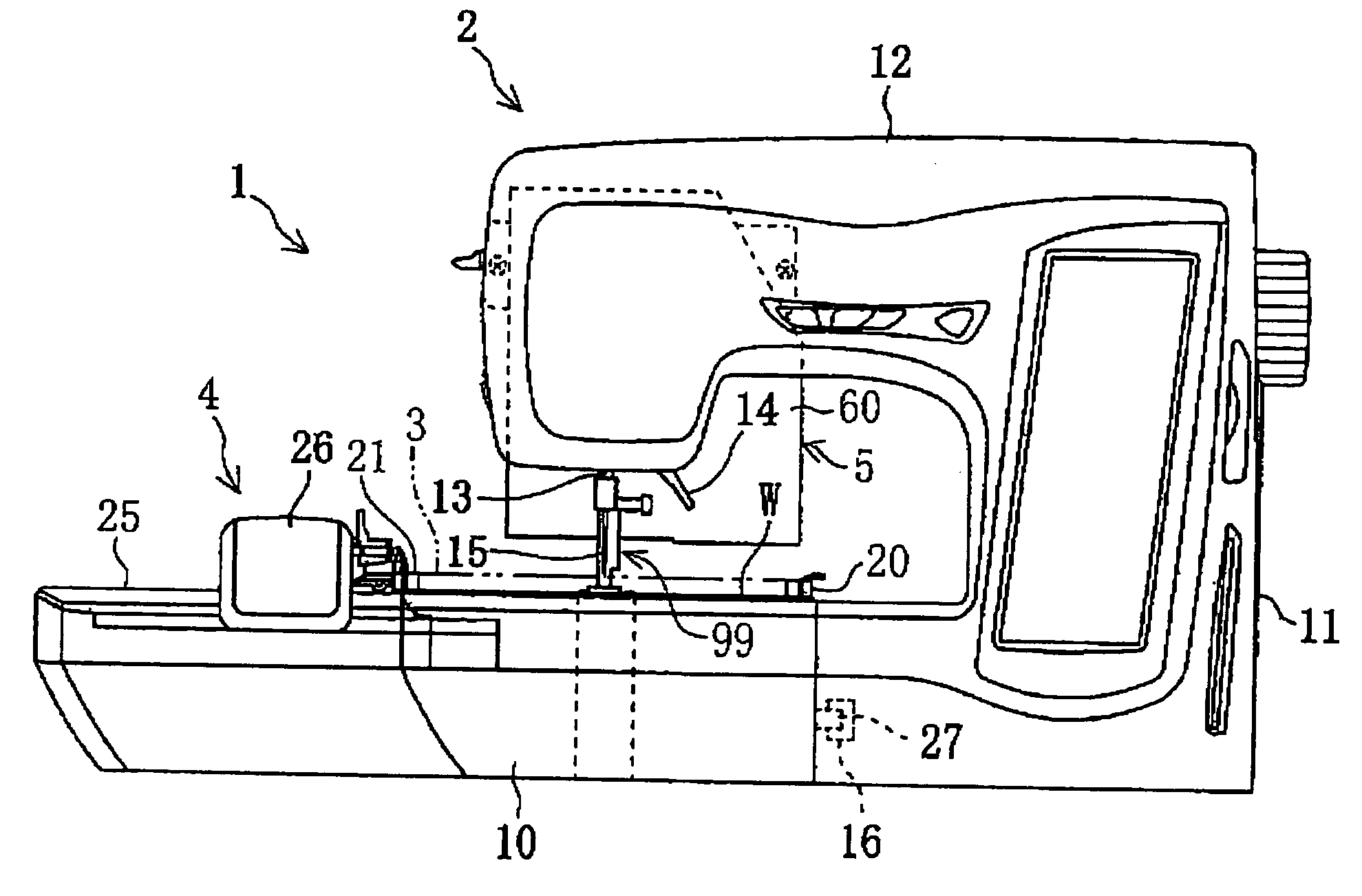

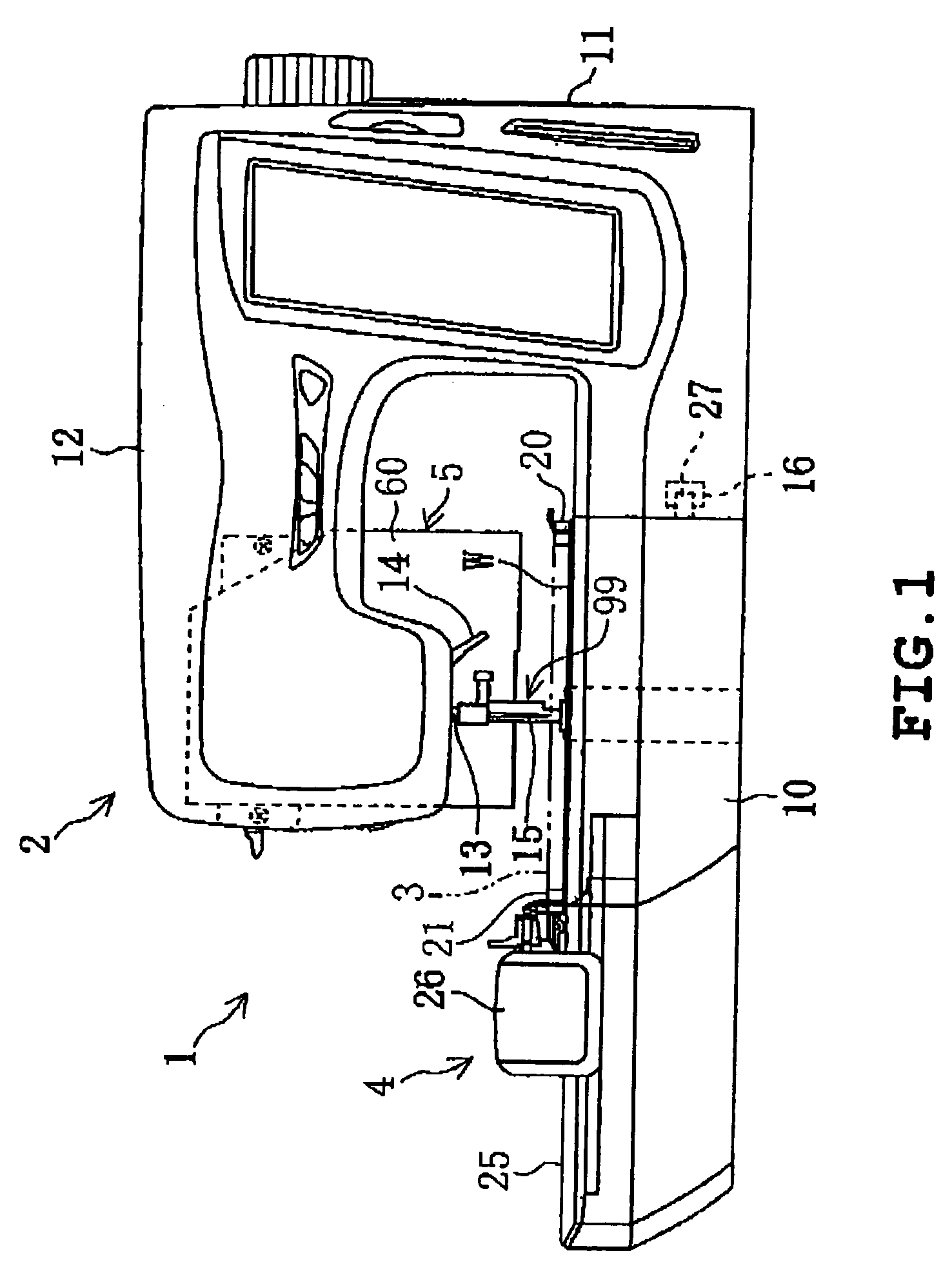

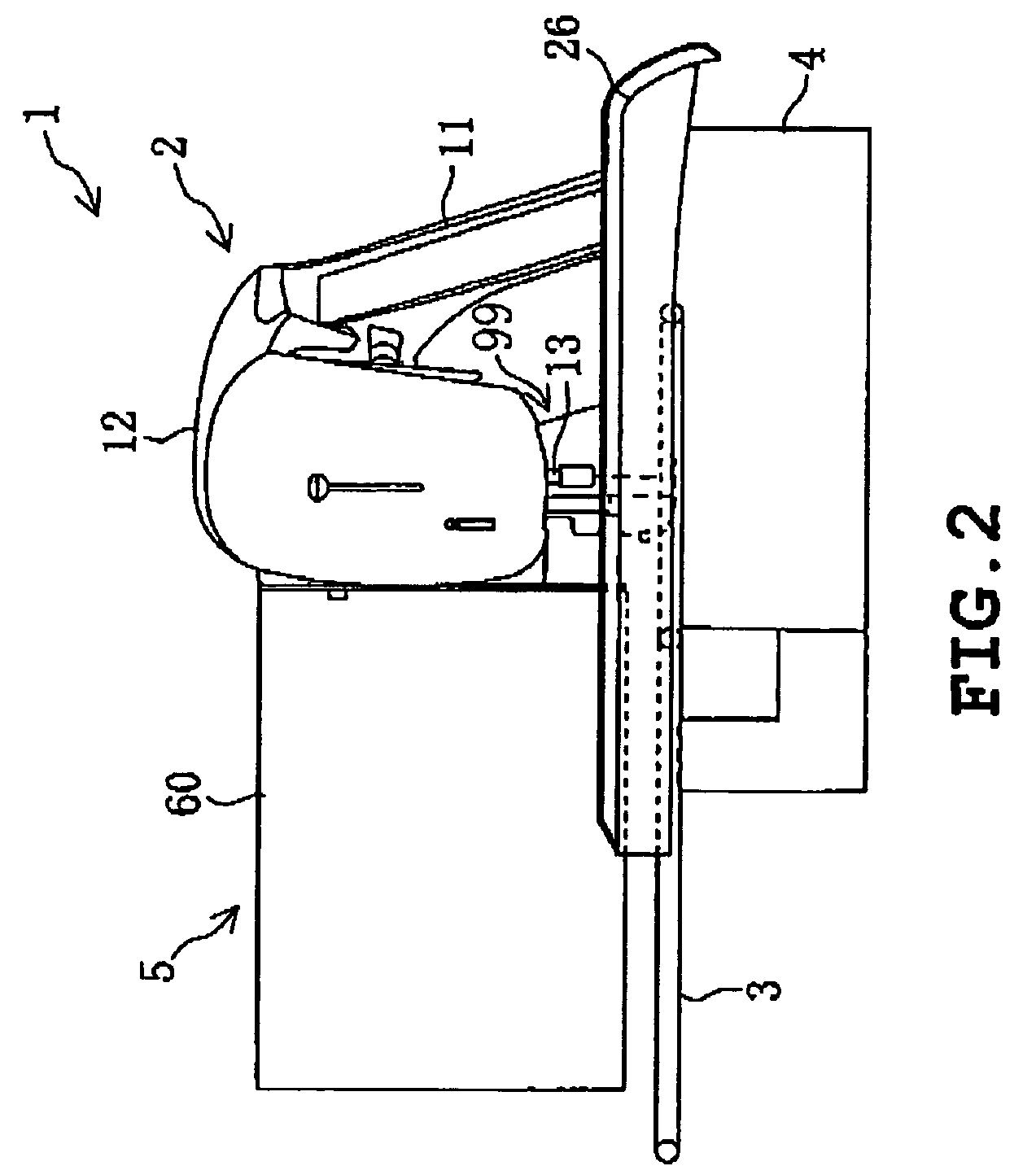

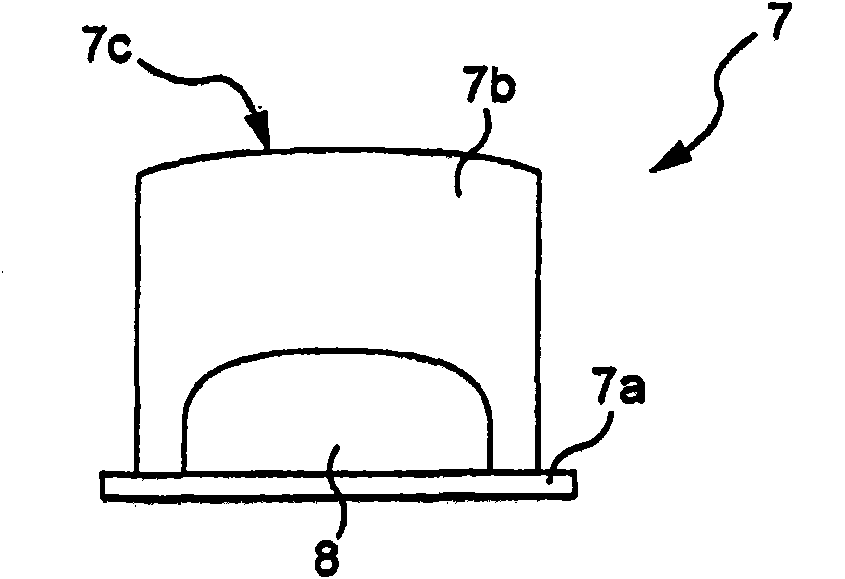

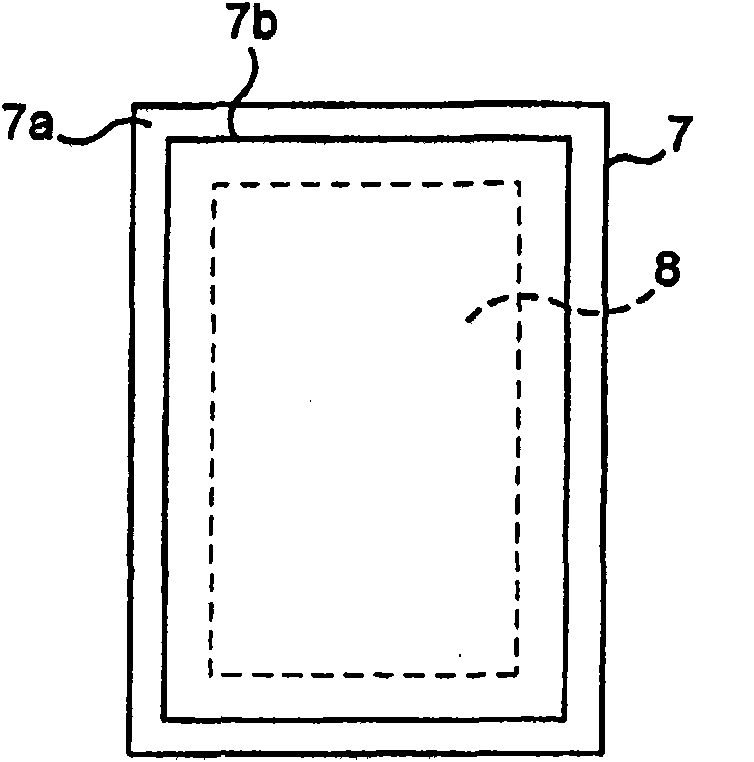

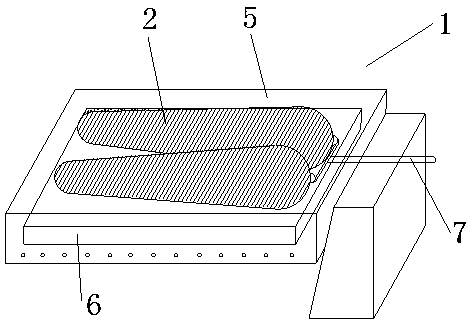

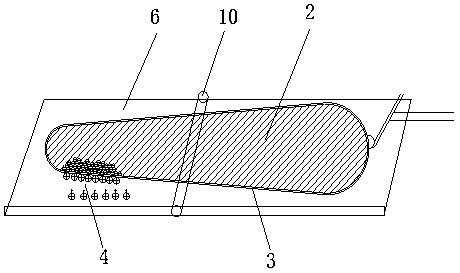

Embroidery Sewing Machine With Printing Function

InactiveUS20080011212A1Increase the areaTypewritersOther printing apparatusEngineeringPerpendicular direction

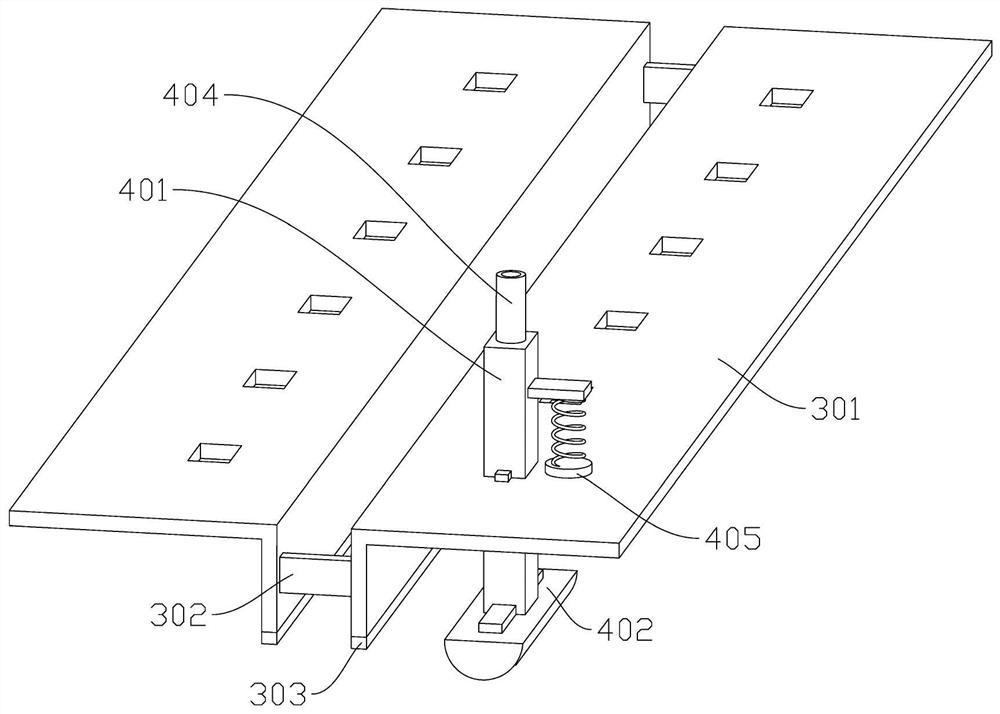

An embroidery sewing machine with printing function (1) including a sewing machine body (2) having a bed (10), a foot (11), an arm (12), and capable of sewing a workpiece cloth (W) by a sewing unit (99); a cloth holding frame (3) holding the workpiece cloth (W) to be sewn; a frame drive unit (4) moving the cloth holding frame 3 independently in two mutually perpendicular directions in a horizontal plane; an ink-jet printer (5) having a print head (61) printing the workpiece cloth (W) held by the cloth holding frame (3); the embroidery sewing machine with printing function (1) characterized in that the frame drive unit (4) includes a first drive mechanism (45) that moves the cloth holding frame (3) in a first direction parallel with a lengthwise direction of the bed (10); and a second drive mechanism (30) that moves the cloth holding frame (3) in a second direction perpendicular to the first direction and the print head (61) of the printer (5) includes nozzle arrays (61c to 61f) aligning a plurality of ink-jet nozzles (61b) parallel in the first direction and the printer (5) prints the workpiece cloth (W) while moving the cloth holding frame (3) in the second direction by the second drive mechanism (30), thereby to increase a printable area K.

Owner:BROTHER KOGYO KK

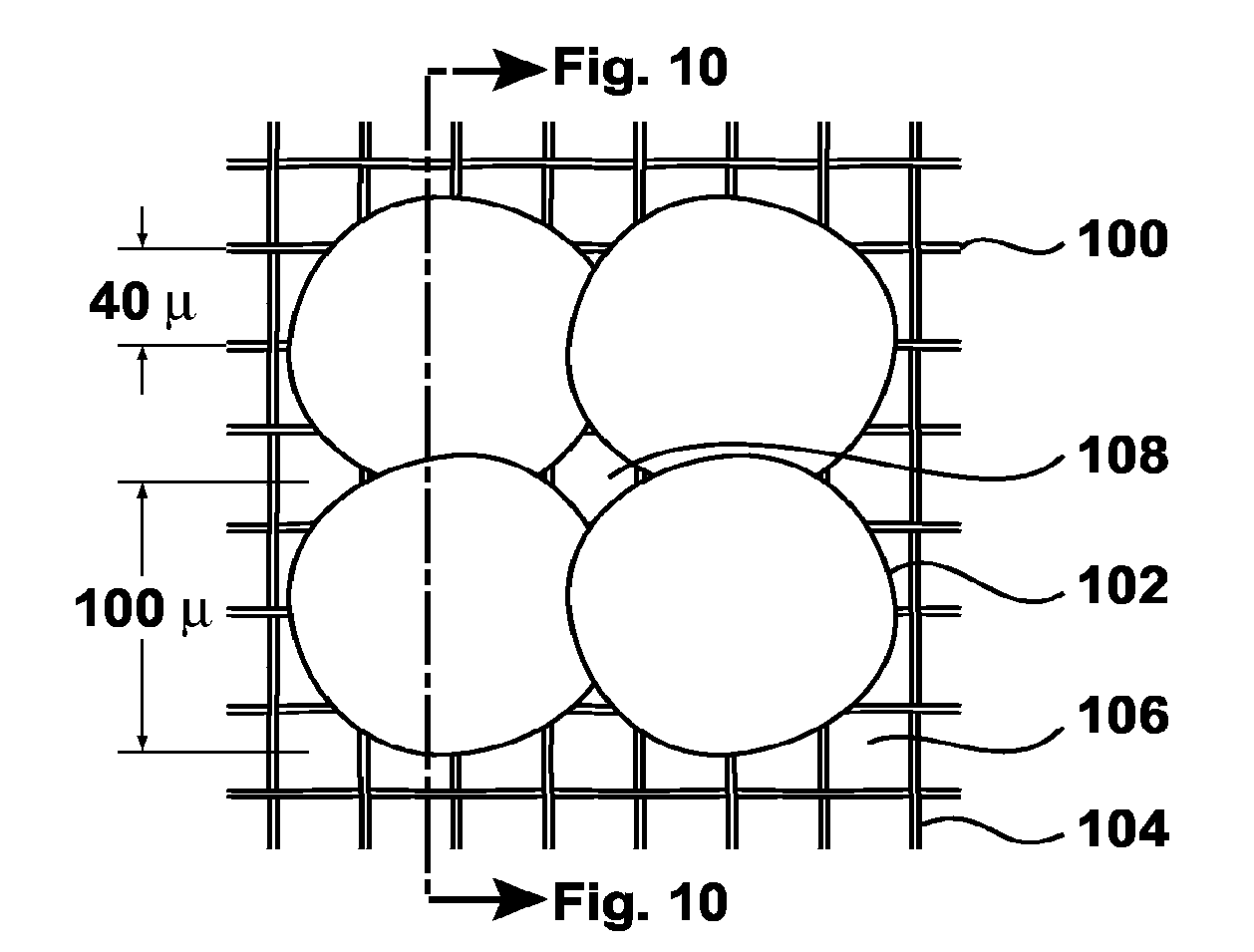

Composition, method and device for digitally coating textile

InactiveUS20110033691A1Good varietyImprove solubilitySucessive textile treatmentsLayered productsFlocculationEmulsion

A finishing composition is described for deposition by dot-on-demand inkjet technique onto a textile substrate. The composition comprises a solution, dispersion or emulsion of a functional finishing agent in a vehicle, wherein the size of particles in the dispersion or emulsion of the finishing composition is less than about 2 microns. By ensuring sufficient fineness of the particles, effective and reliable droplet deposition may proceed without clogging. Of significance, the composition should not be subject to flocculation or sedimentation during use.

Owner:TEN CATE ADVANCED TEXTILES BV

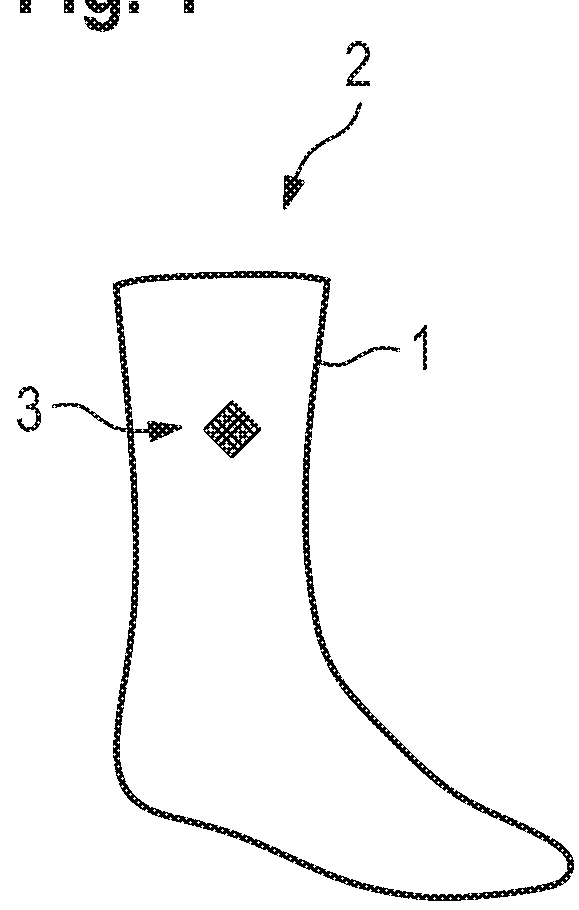

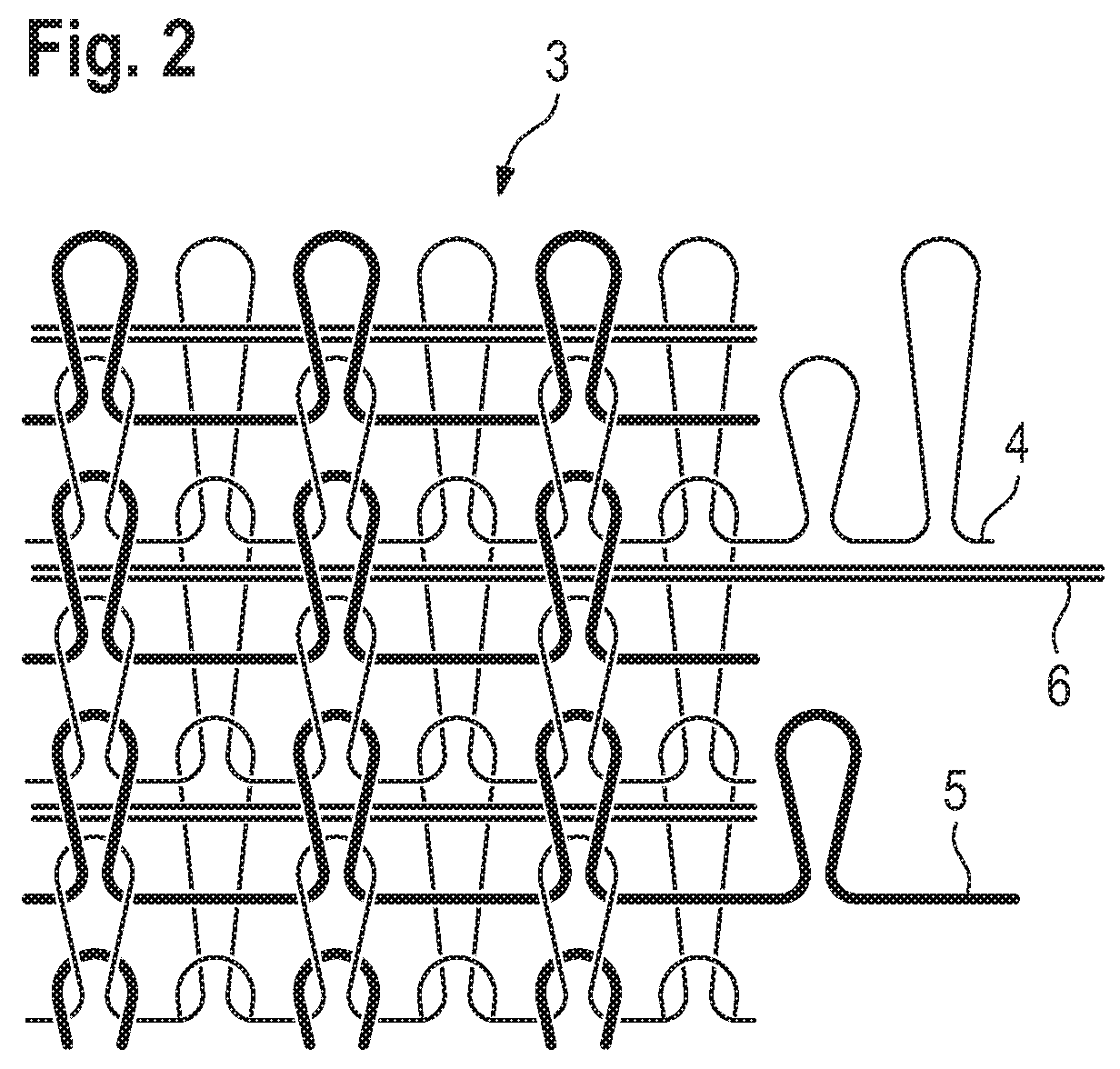

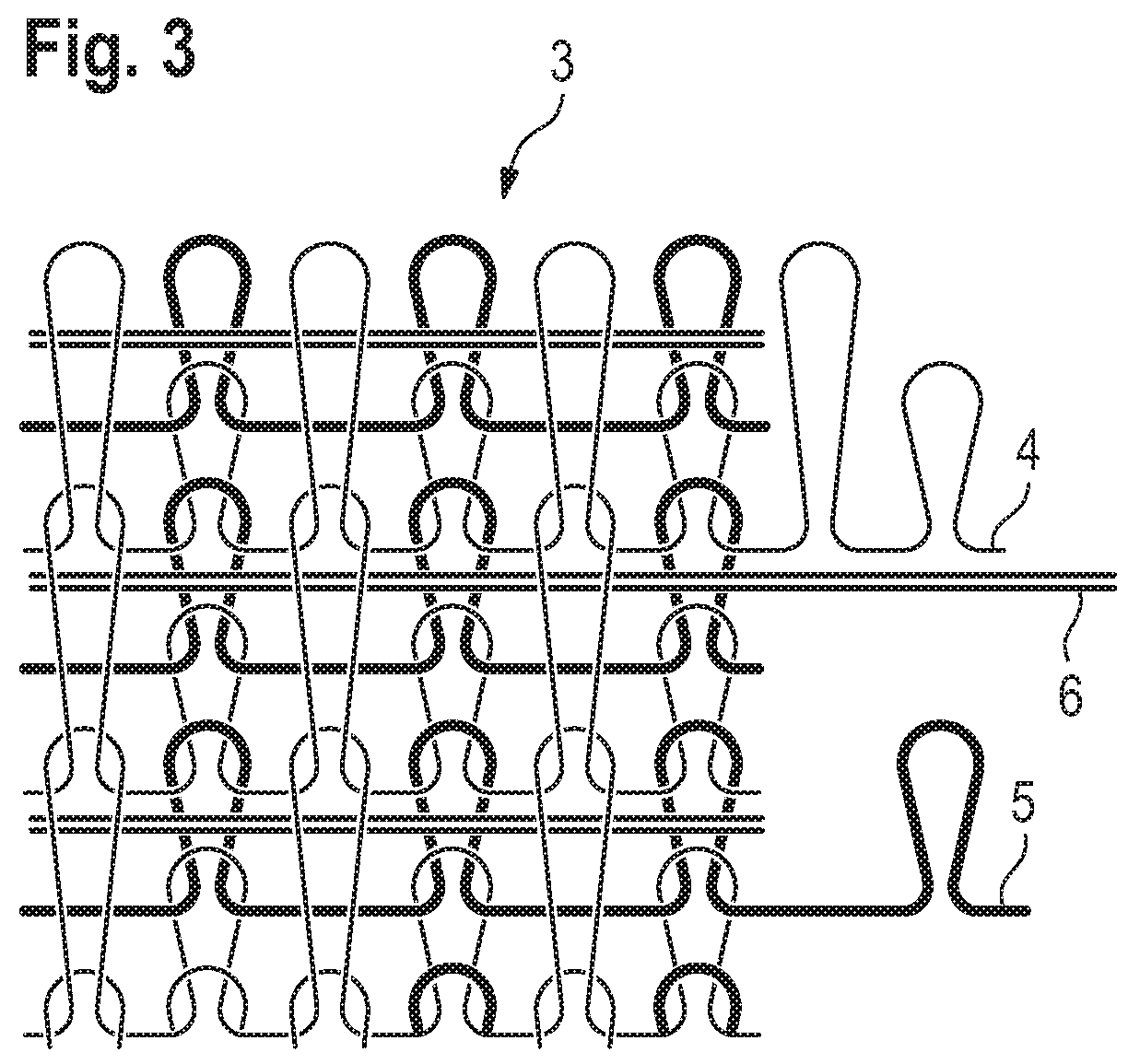

Compression knit part, compression garment, dyeing method for compression knit part, and production method for dyed compression garment

InactiveUS20180163328A1Easy to dyeReduce water consumptionWeft knittingLiquid/gas/vapor article treatmentEngineeringCompression garment

A compression knit part composed of a compression knit including a first ground thread and a second ground thread, wherein the first ground thread is composed at least at its surface of a manufactured polyamide fiber that accepts a first dye but not a second dye, and the second ground thread is composed at least at its surface of a manufactured polyester fiber which accepts the second dye but not the first, and a weft thread configured as compression thread.

Owner:MEDI GMBH & CO KG

Customer-created textiles and customer-oriented garment dyeing machine

ActiveUS8295970B2Improve experienceUniform coverageTextile treatment containersFibre treatmentEngineeringSingle item

Customers obtain customized textile materials by selecting style, shape, size, pattern and color for an undyed textile product. Based on a selection made by the customer, the textile product is transformed by a dyeing operation performed on a single item (or multiple items selected to be dyed the same) to yield a product, such as a shirt, pants, or jacket, which has a color and pattern of his or her own choosing, in the size and style he or she desires. The process can be performed in a retail setting using a dye apparatus which allows the process to be viewed by the customer. To enhance the educational and entertainment experience of the customer, the dyeing operation can be performed in a transparent tank or water kettle in the retail outlet so that the customer can view, for example, the garment as it is being dyed to the customer's specifications.

Owner:TINTORIA PIANA US INC

Customer-created textiles and method of producing same

Customers obtain customized textile materials by selecting style, shape, size, pattern and color for an undyed textile product. Based on a selection made by the customer, the textile product is transformed by a dyeing operation performed on a single item to yield a product, such as a shirt, pants, or jacket, which has a color and pattern of his or her own choosing, in the size and style he or she desires. The process can be performed in a retail setting using a dye machine which allows the process to be viewed by the customer. Preferably, the textile material is constructed from yarns which include cationic cotton alone or in combination with natural cotton or other natural or synthetic fibers, and using anionic dyes, such as a fiber reactive dye, such that the dye is exhausted during the process and effluent from the dye machine is environmentally friendly without excess dye, salts, and alkalis.

Owner:TINTORIA PIANA US INC

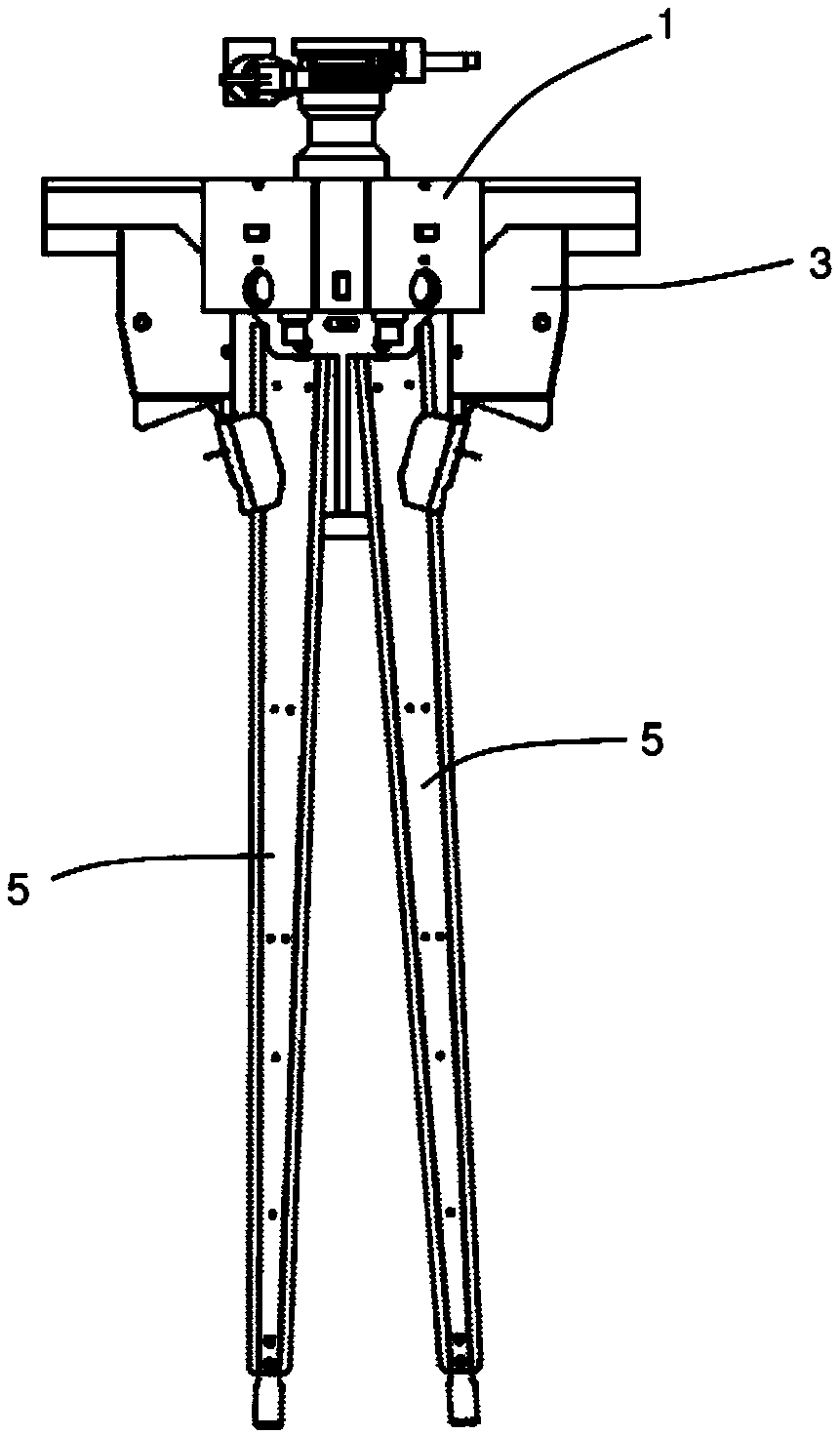

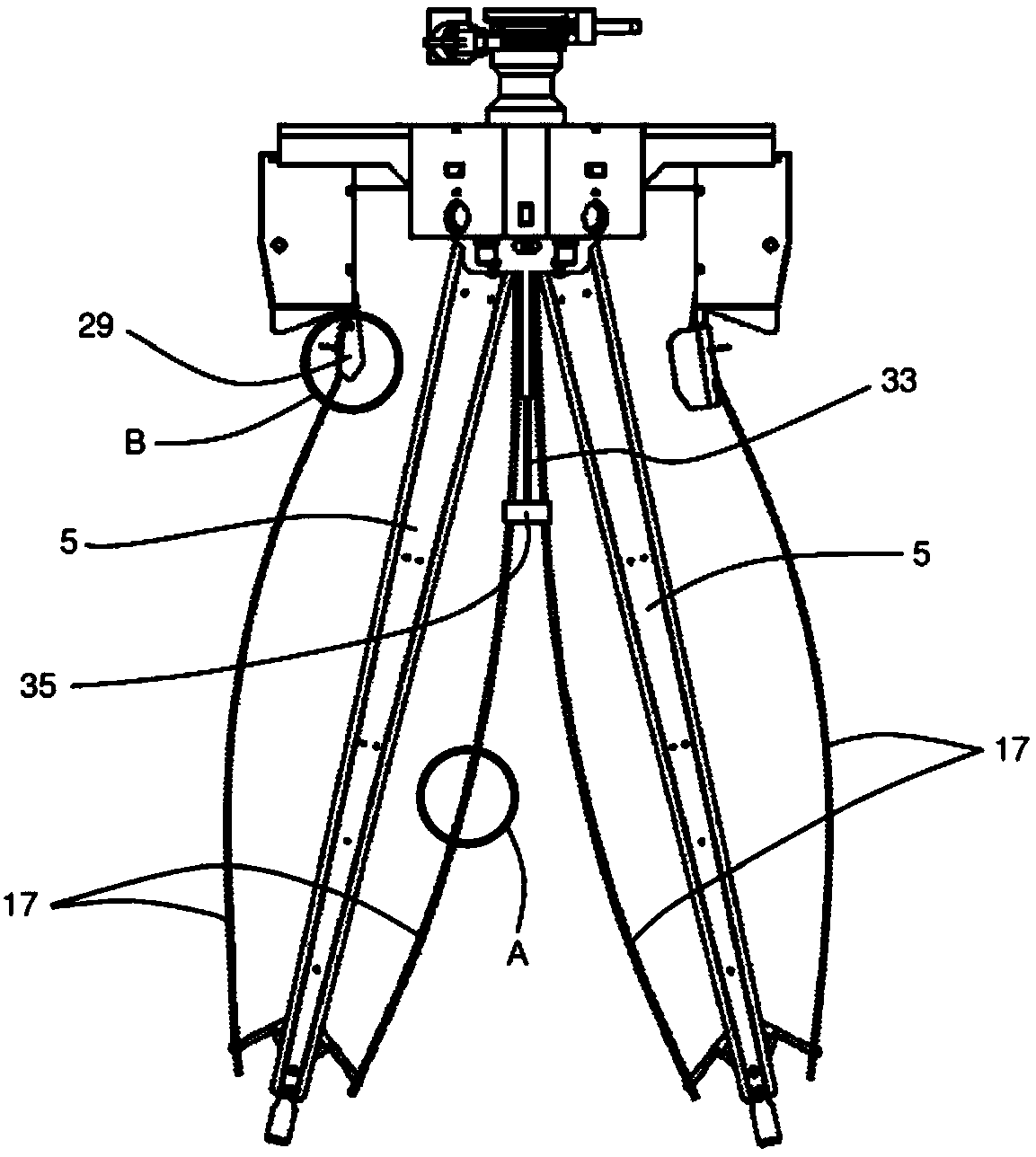

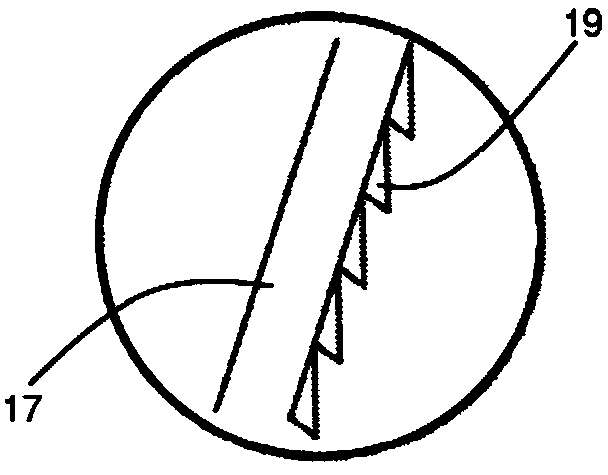

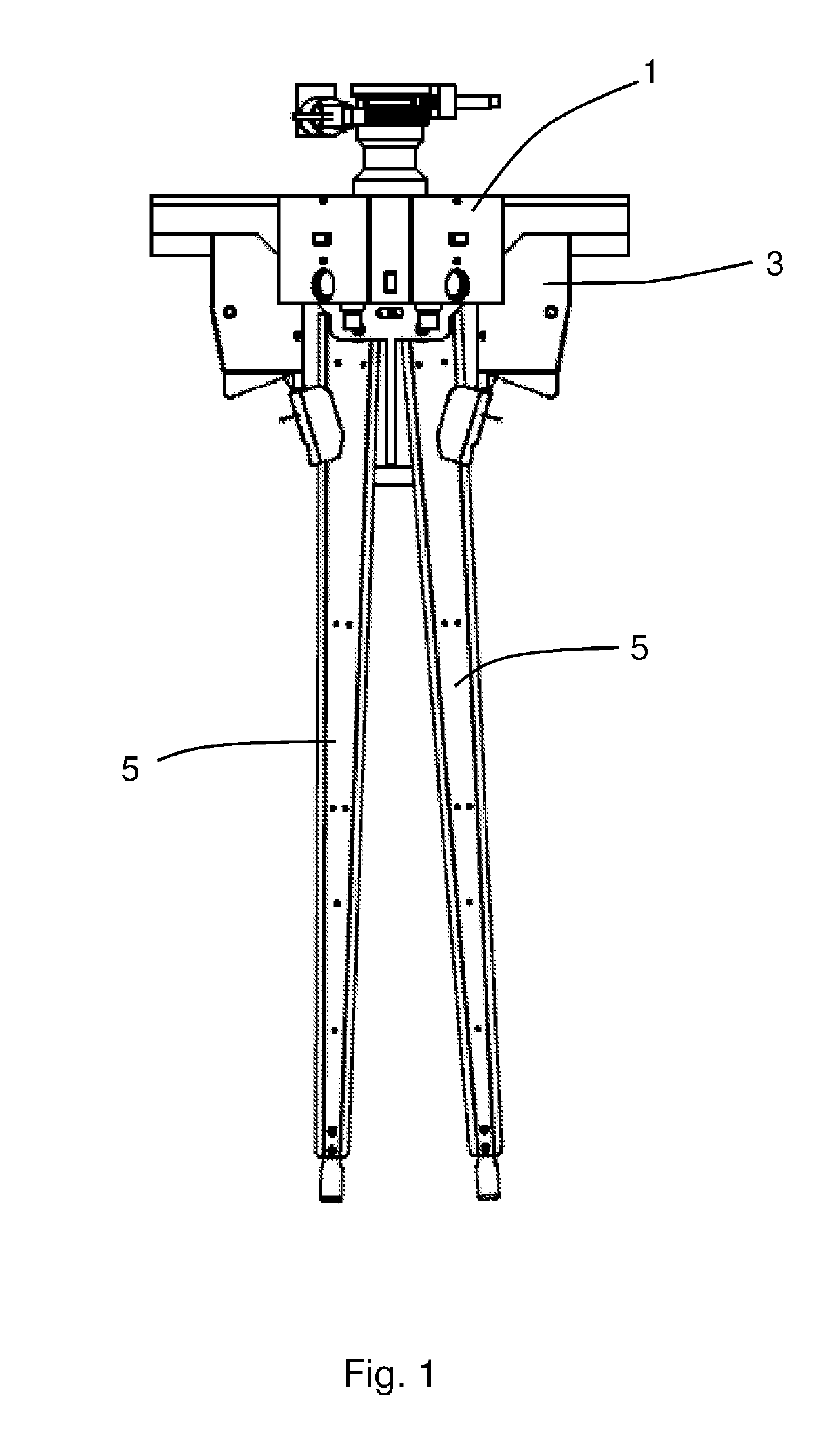

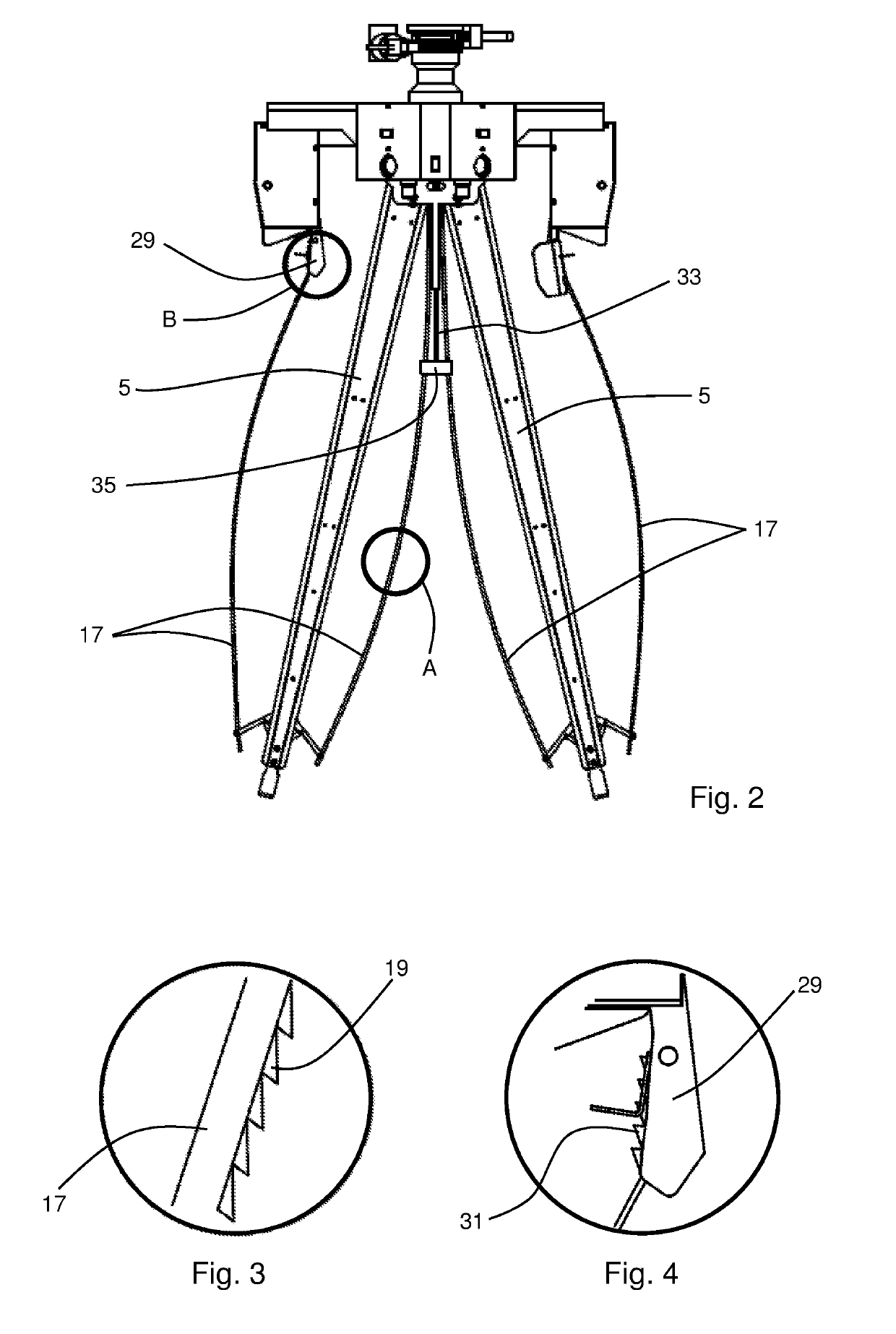

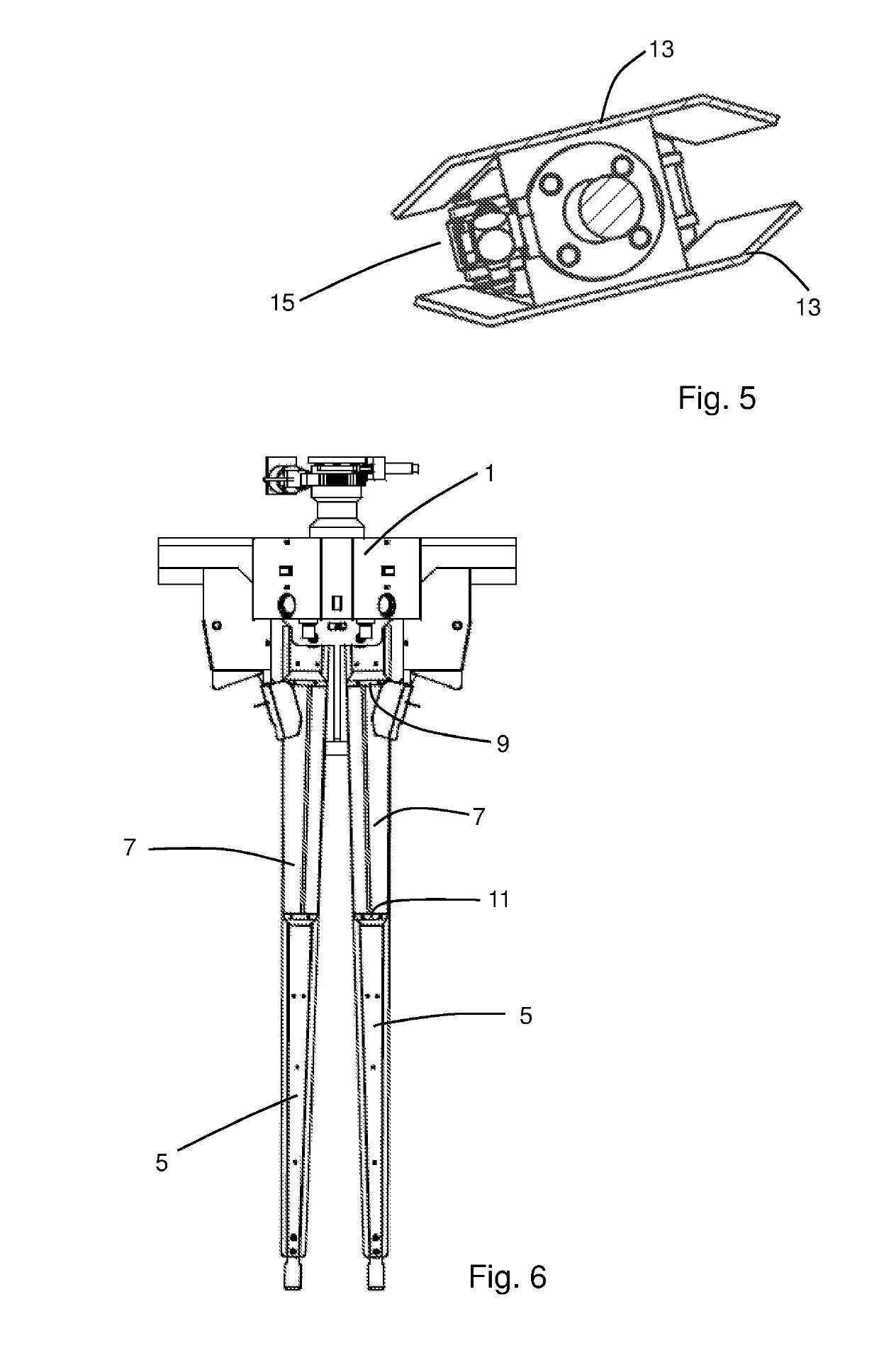

Mannequin for surface treatment of trousers

The invention relates to a mannequin for the surface treatment of trousers, which comprises an upper support structure (1) from which two legs (5) extend, each leg (5) having an inflatable balloon (7)disposed on the rear part thereof. The outer lateral section (41) of each balloon (7) is folded at least once around a folding line (47) that extends from the upper edge (9) to the lower edge (11) ofthe balloon (7). The upper edge (9) is secured to the upper end on the rear of the leg (5) and the lower edge (11) is secured at an intermediate point on the rear of the leg (5), such that the partsof the edges (9, 11) corresponding to the outer lateral section (41) are also secured to the leg (5) of the mannequin.

Owner:JEANOLOGIA

Embroidery sewing machine with printing function

An embroidery sewing machine with a printing function includes a sewing machine body having a bed, a foot, an arm, and capable of sewing a workpiece cloth by a sewing unit; a cloth holding frame holding the workpiece cloth; a frame drive unit moving the cloth holding frame independently in two mutually perpendicular directions in a horizontal plane; an ink-jet printer having a print head printing the workpiece cloth. The print head of the printer includes nozzle arrays with each nozzle array having a plurality of ink-jet nozzles aligned parallel in the first direction, and the printer prints the workpiece cloth while moving the cloth holding frame in the second direction.

Owner:BROTHER KOGYO KK

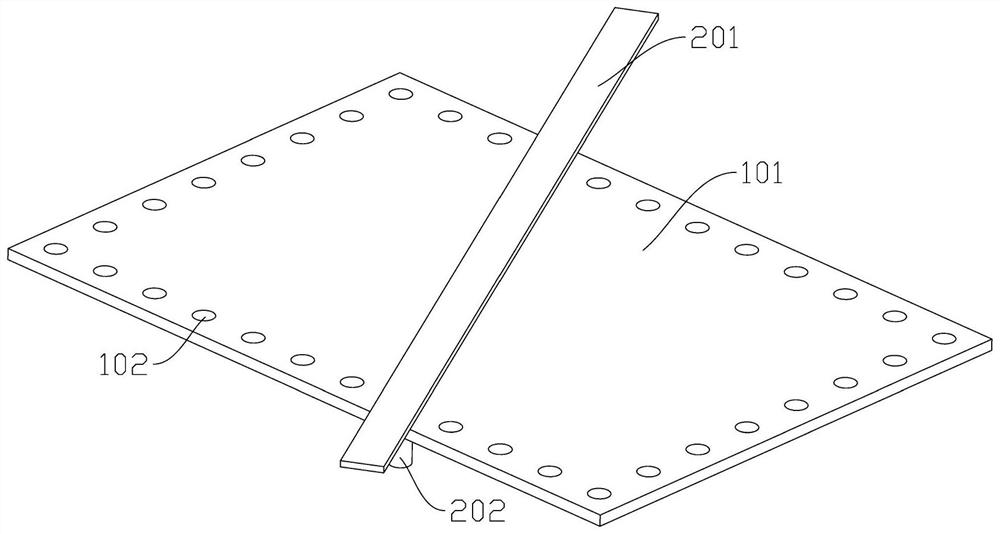

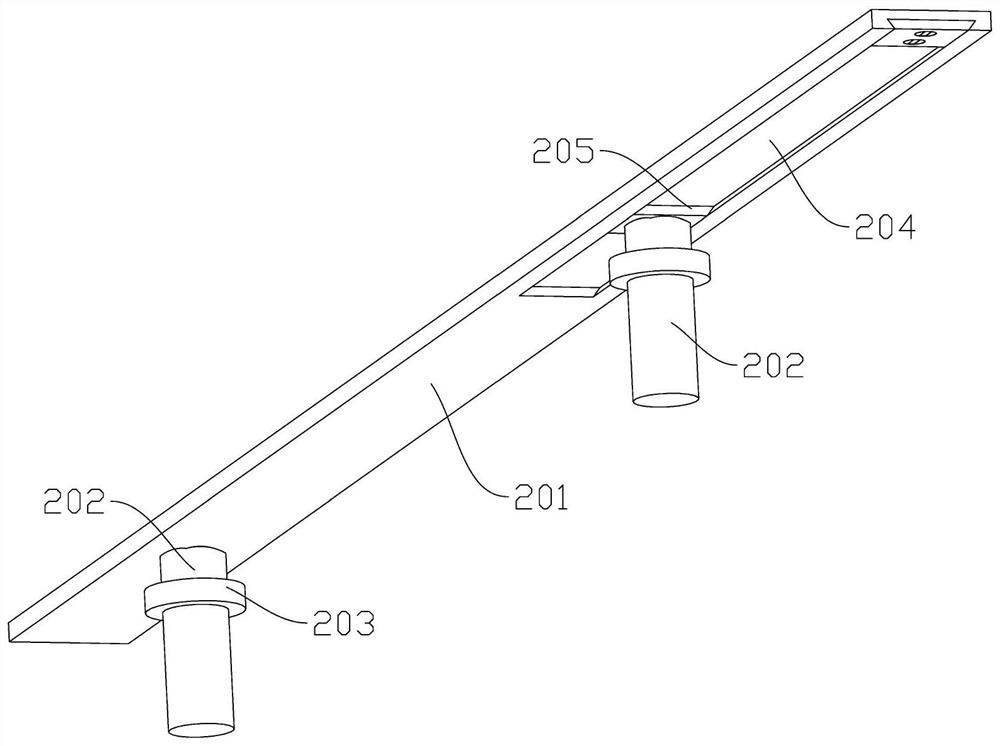

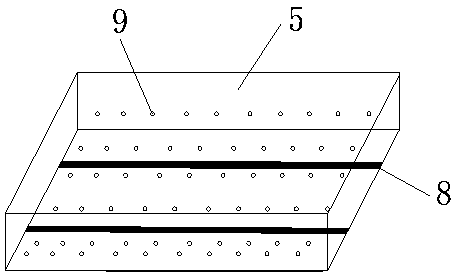

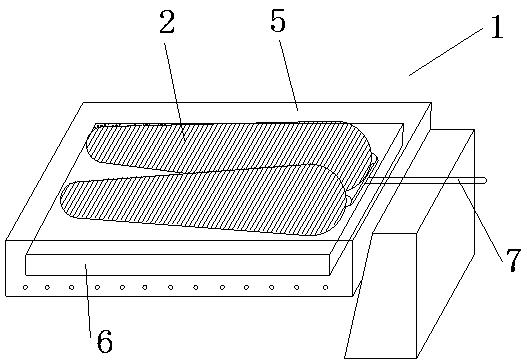

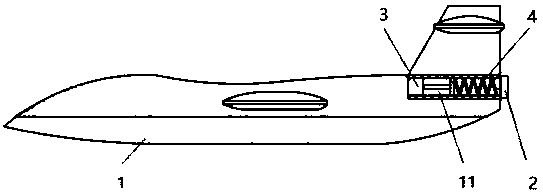

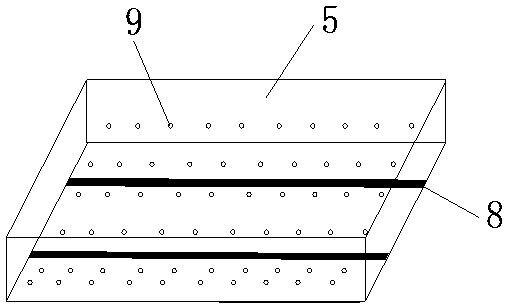

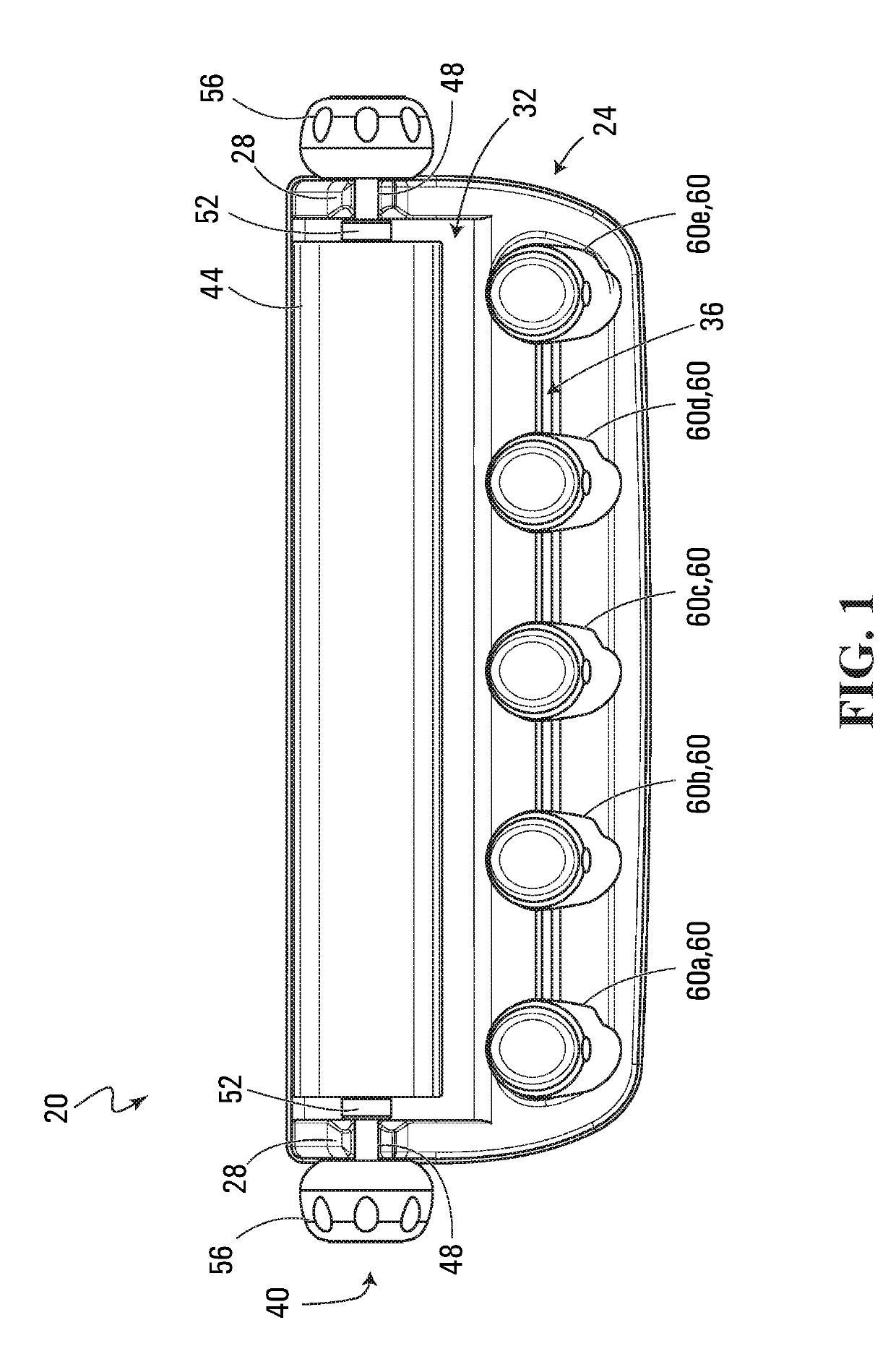

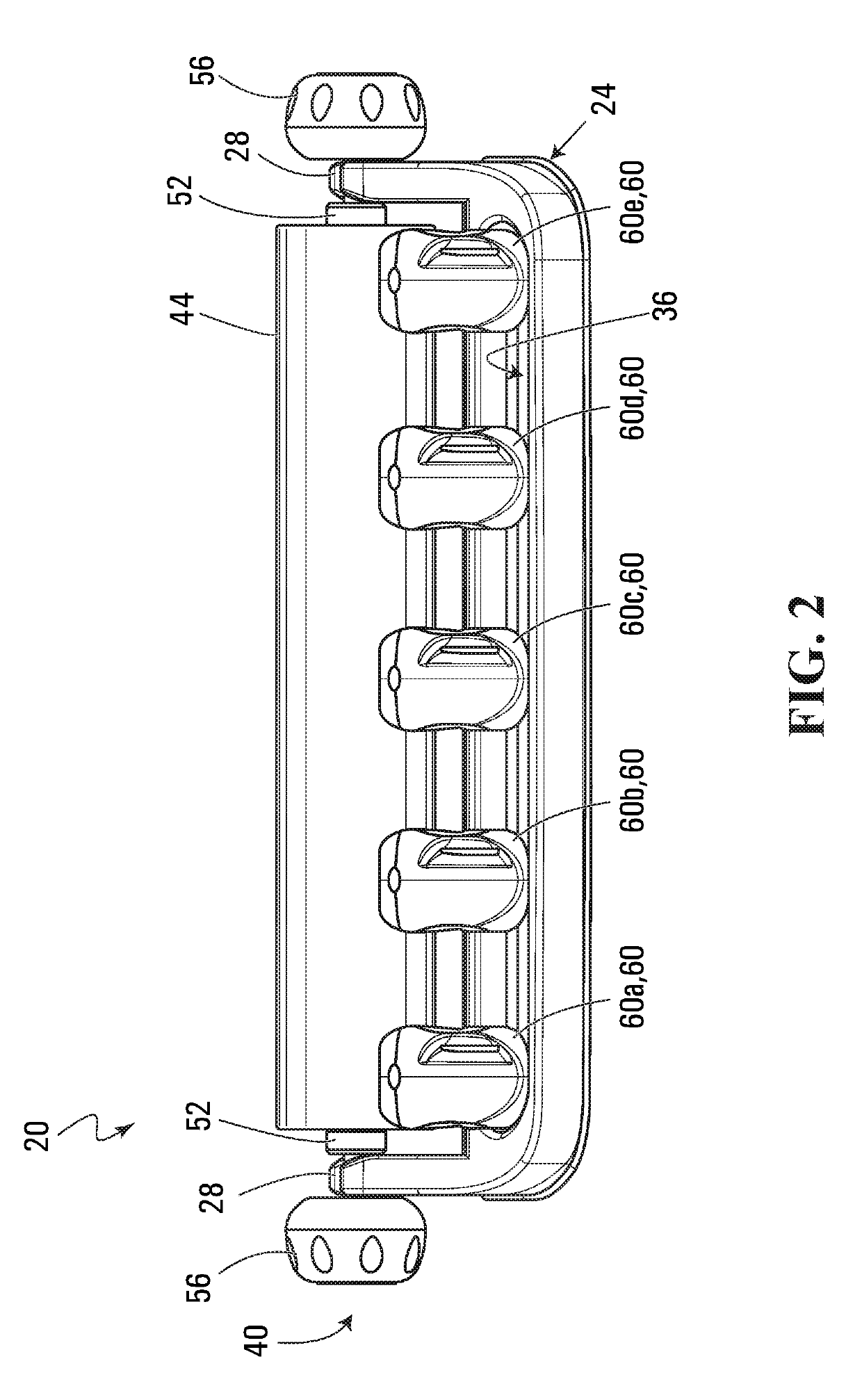

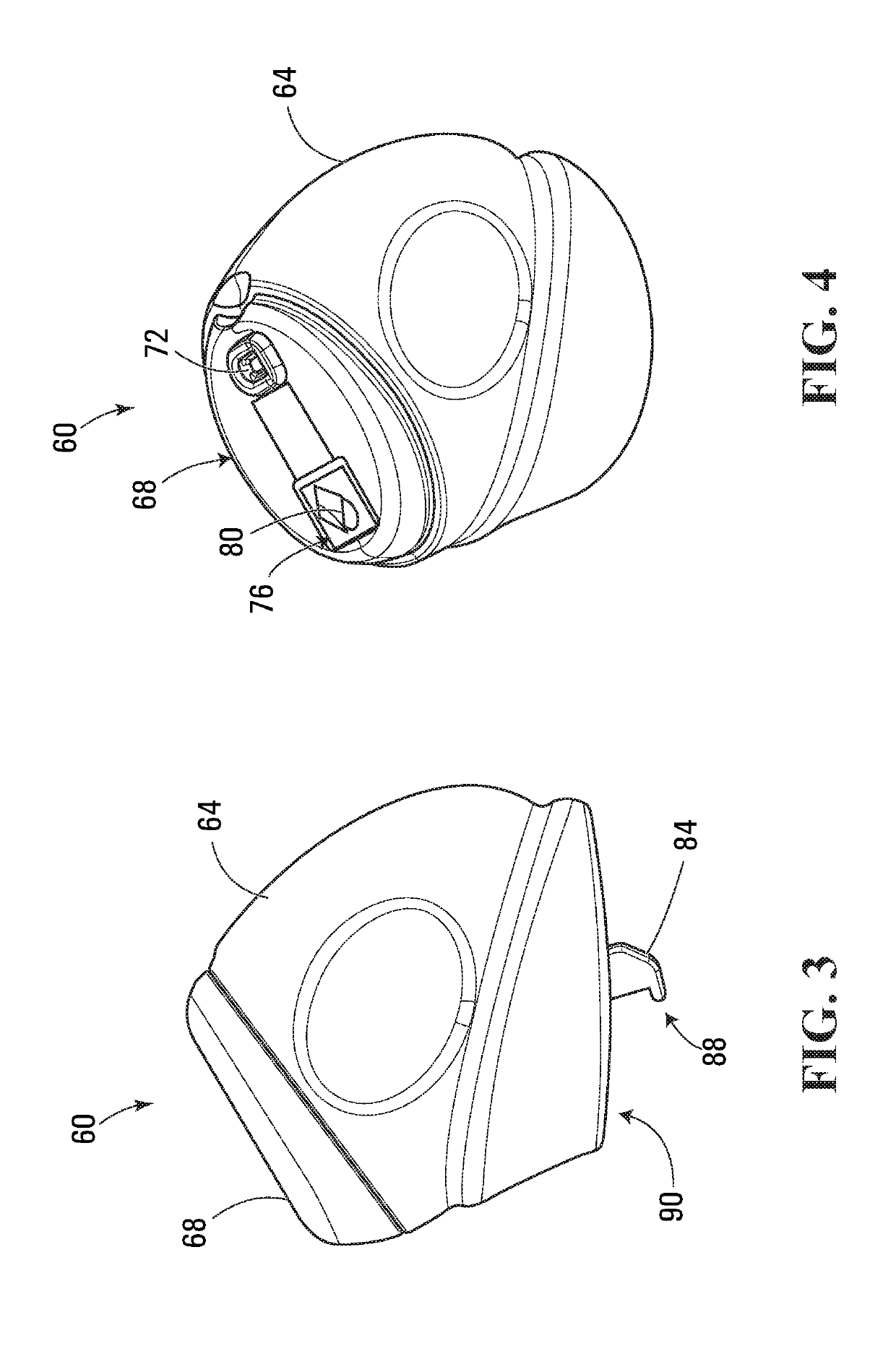

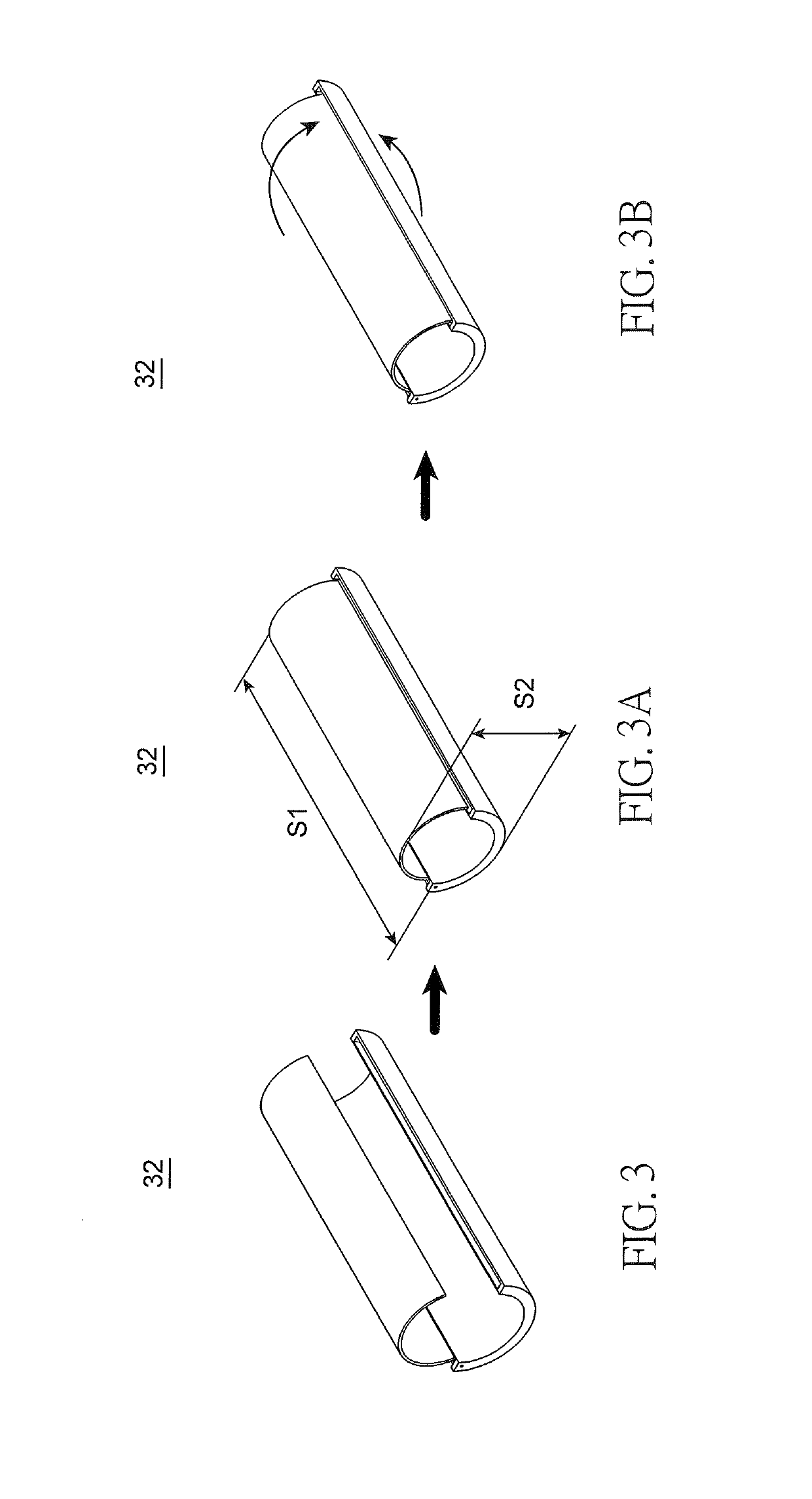

Gradually-changed tie-dyed trousers preparation system and method

InactiveCN113279179AChange distanceTo achieve the effect of separationTextile treatment carriersArticle parts treatmentEngineeringMechanical engineering

The invention belongs to the technical field of fabric dyeing, and particularly relates to a gradually-changed tie-dyed trousers preparation system and method. The invention provides the gradually-changed tie-dyed trousers preparation system which comprises a bundling device used for shaping trousers; the bundling device comprises a clamping part used for clamping the trousers and a separating part used for separating different dyeing areas; the separating part is connected with the clamping part through a control assembly, and the distance between the separating part and the clamping part can be changed; according to the system, trousers with gradually-changed colors can be processed; the method for processing the gradually-changed tie-dyed trousers comprises the following steps that S1, the trousers are placed on a supporting plate, the position between the trousers and a binding plate is adjusted, and the positions, not needing to be dyed, of the trousers are shielded through tying; S2, inserting columns penetrate through corresponding sleeve holes, and the binding plate and the supporting plate are firmly attached by tightening threaded pieces; and S3, the position between a dye flowing channel and the supporting plate is adjusted through the control assembly, and the different dyeing areas on the trousers are separated through the separation part.

Owner:张景生

Supercritical carbon dioxide art dyeing method

InactiveCN101824760ARealize cleaner productionImprove the artistic effectDyeing processLiquid/gas/vapor textile treatmentDisperse dyeEngineering

The invention relates to a supercritical carbon dioxide art dyeing method which comprises the following steps of: embroidering a fabric to be dyed by utilizing a needle, a thread, a rope, a wood rod and medium-thickness type cotton or a mixture thereof according to a predesigned pattern to cover the dyeing preventing part of the fabric to be dyed according to the design of the pattern; placing dye and the embroidered fabric to be dyed, which is fixed to a distributor, into a supercritical carbon dioxide dyeing device and dyeing at the temperature of 70-150 DEG C and the pressure of 18-30MPa for 50-100 minutes; then recovering carbon dioxide and the dye at the pressure of 4-5MPa and the temperature of 25-40 DEG C; and disassembling a covering object of the dyed fabric and ironing the dyed fabric. The fabric to be dyed is a blending fabric of terylene, polyester wool and polyester cotton, and the dye is dispersing dye; and in the embroidering process, the fabric to be dyed is subjected to pinched binding, string binding, laminated binding, knitting and binding and the mixture method thereof. The invention has the characteristics of short process flow, strong art effect, low comprehensive cost and no environmental pollution; and the product meets the requirement of GB18401-2003.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Customer-Created Textiles and Method of Producing Same

Customers obtain customized textile materials by selecting style, shape, size, pattern and color for an undyed textile product. Based on a selection made by the customer, the textile product is transformed by a dyeing operation performed on a single item to yield a product, such as a shirt, pants, or jacket, which has a color and pattern of his or her own choosing, in the size and style he or she desires. The process can be performed in a retail setting using a dye machine which allows the process to be viewed by the customer. Preferably, the textile material is constructed from yarns which include cationic cotton alone or in combination with natural cotton or other natural or synthetic fibers, and using anionic dyes, such as a fiber reactive dye, such that the dye is exhausted during the process and effluent from the dye machine is environmentally friendly without excess dye, salts, and alkalis.

Owner:TINTORIA PIANA US

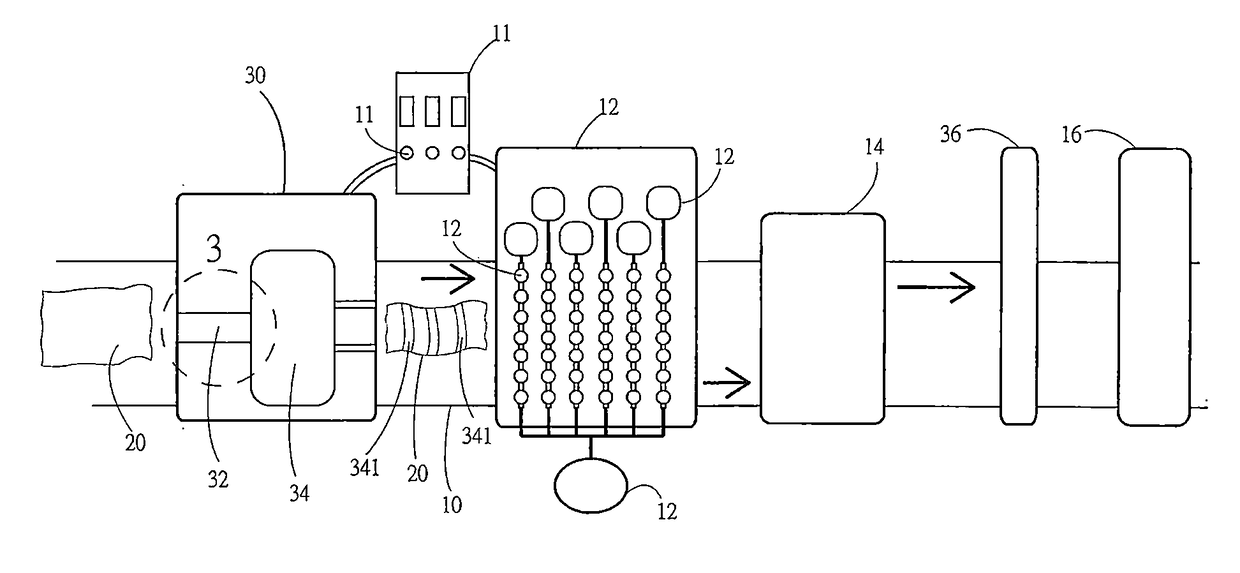

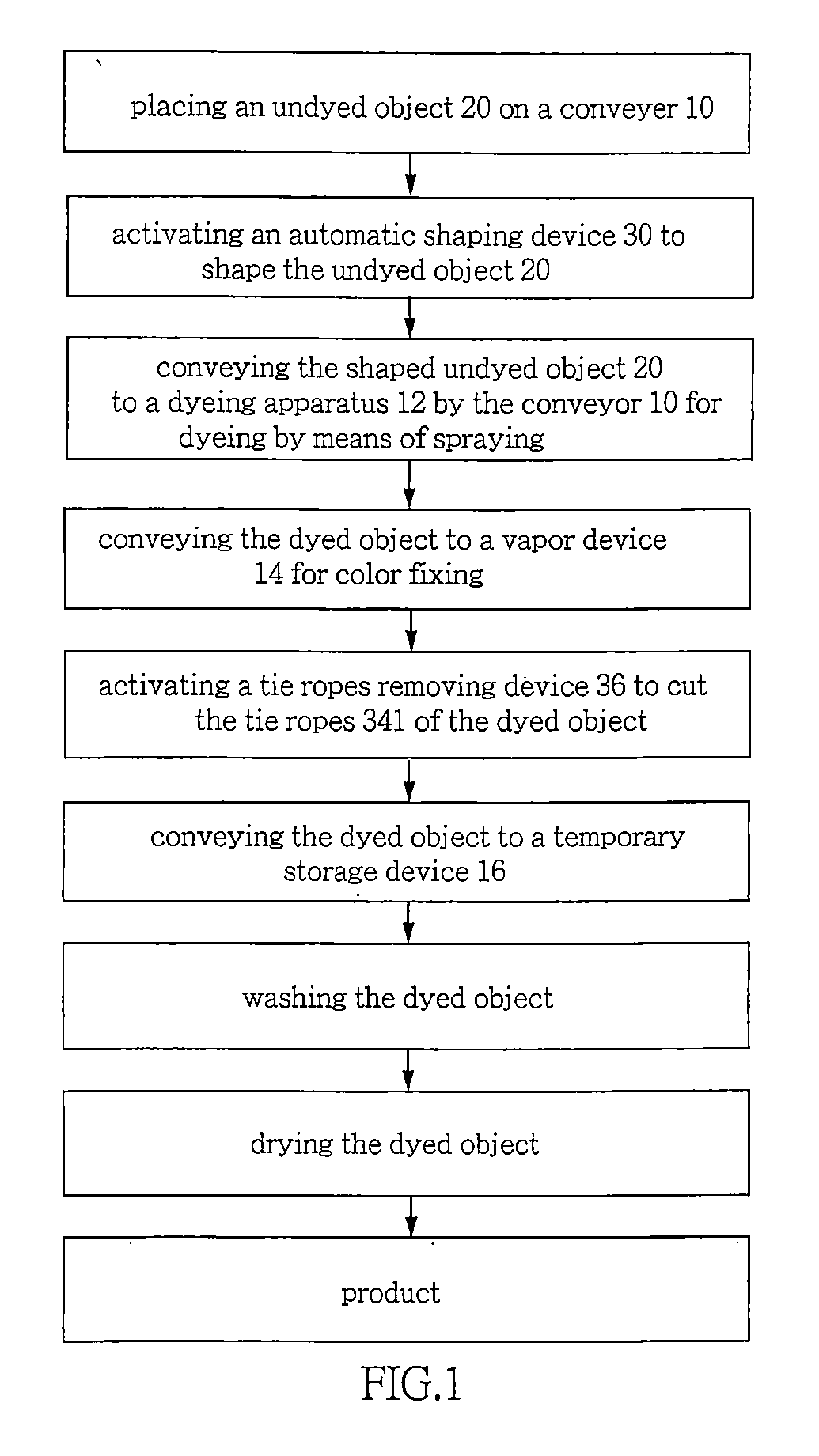

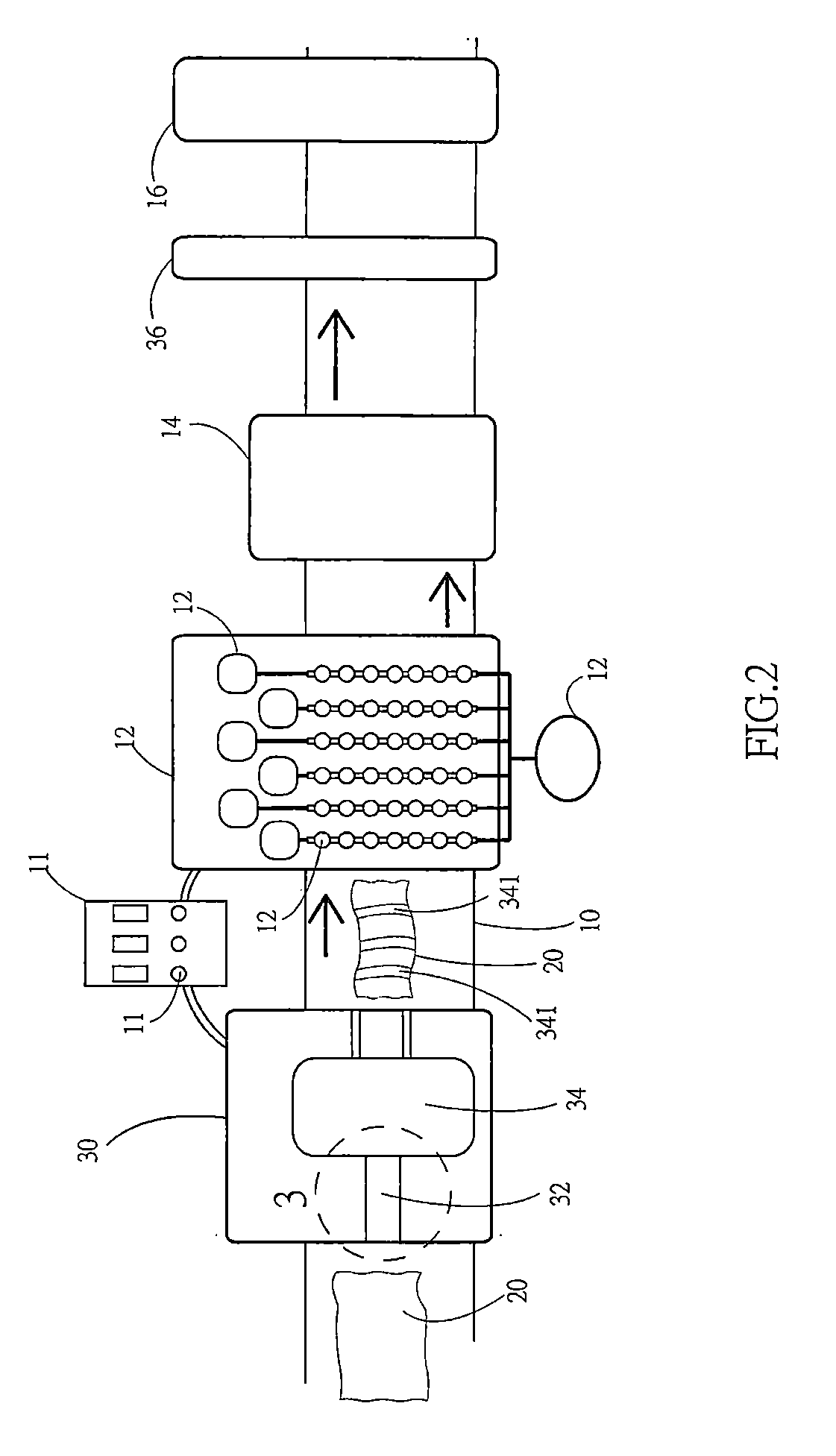

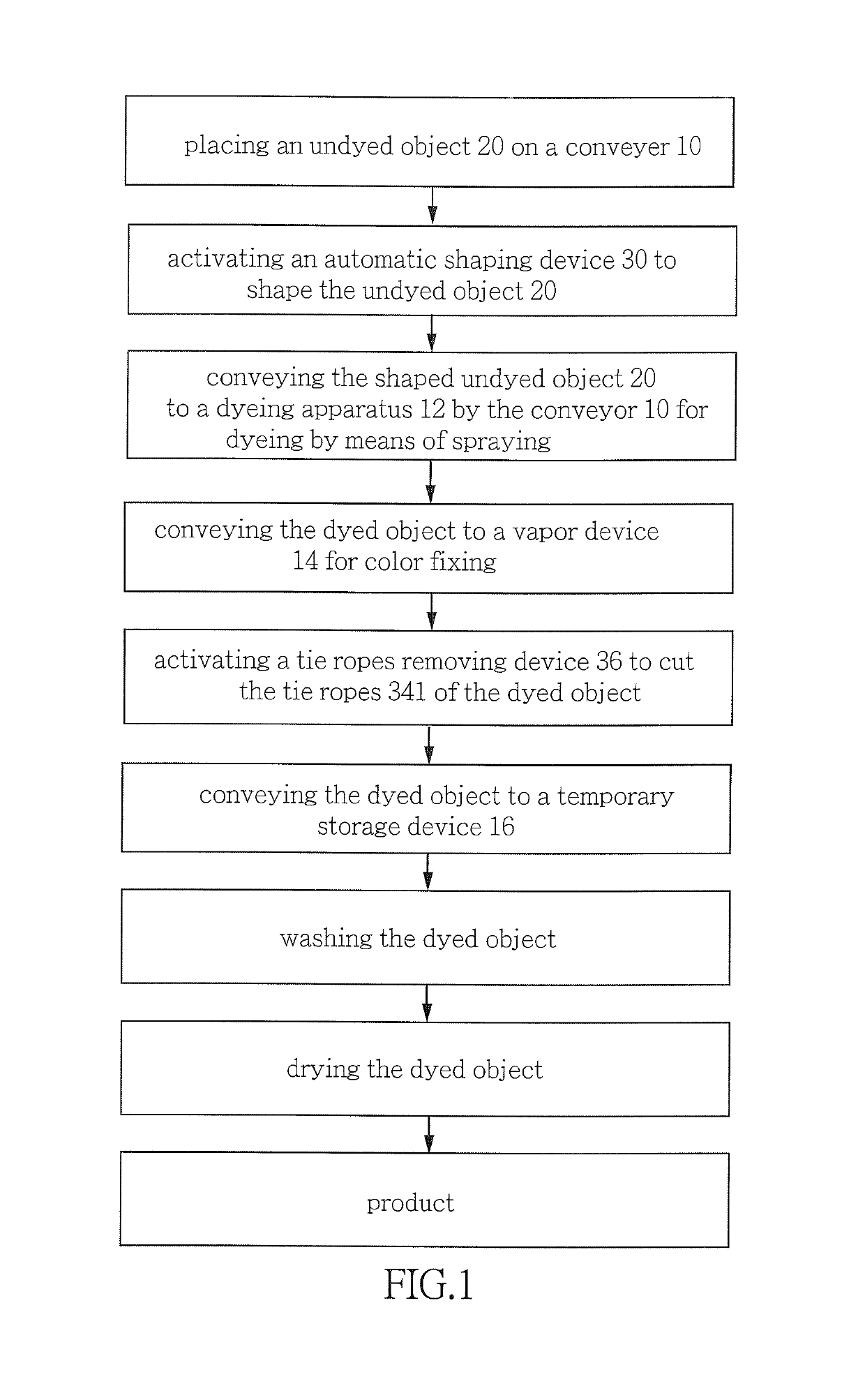

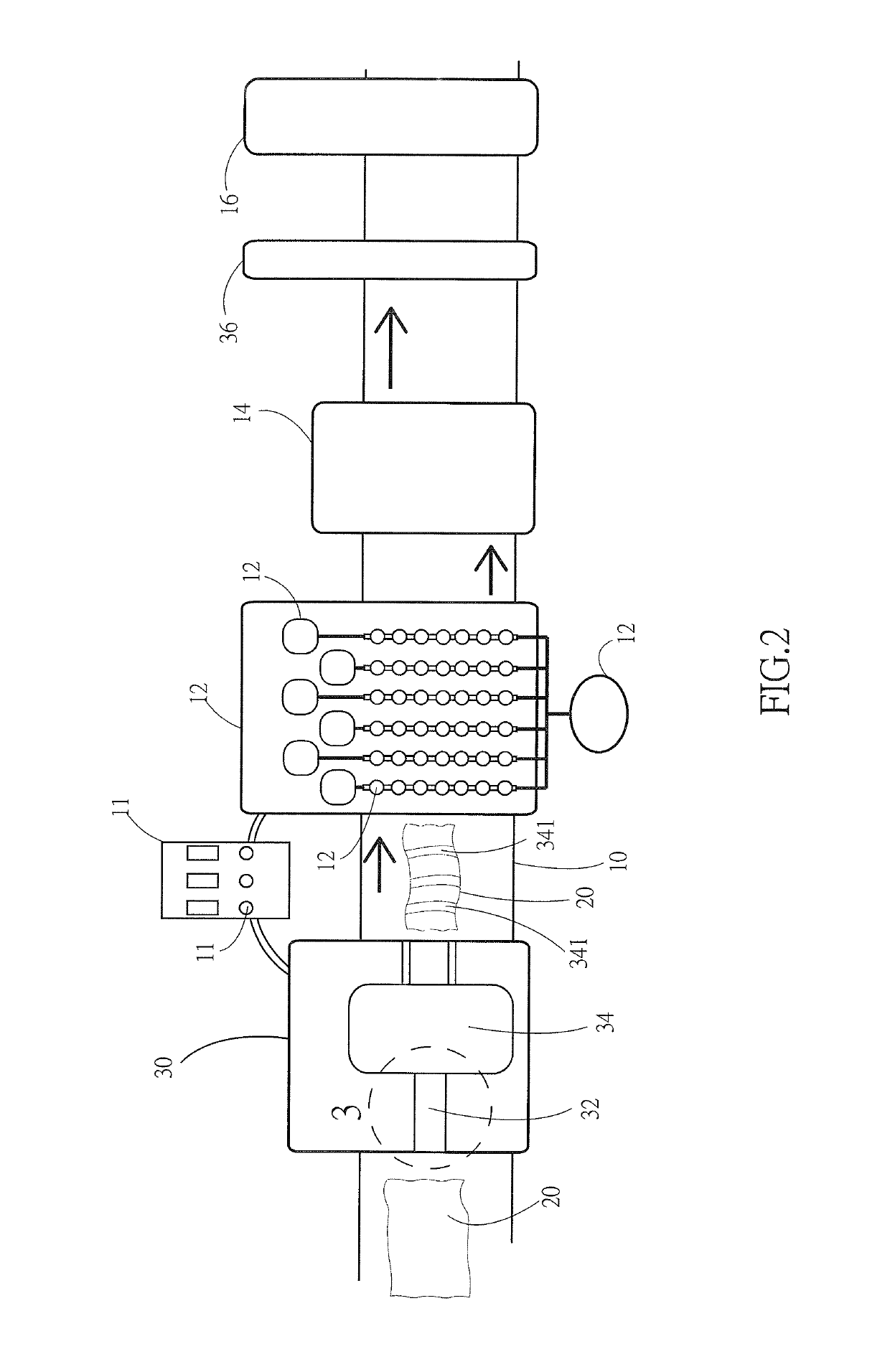

Automatically Color Mix Dyeing Process

ActiveUS20180223476A1Increase productionLower water costsOrnamental textile articlesKnottingEngineeringMechanical engineering

An automatic color mix dyeing process includes activating an automatic shaping device to shape an undyed object as a cylinder and tightening same; conveying the undyed object to a dyeing apparatus by means of spraying wherein the dyeing apparatus includes rows of spray devices, dye containers for containing dyes of different colors, each dye container being in fluid communication with the row of spray devices, a pump for moving the dyes in the dye containers to the rows of spray devices, and a control device for controlling the rows of spray devices to control a spray sequence, a spray time, and a spray quantity of dye; conveying the dyed object from the dyeing apparatus to a vapor device for color fixing wherein the dyed object is impregnated with hot vapor to obtain a finished object; cutting the tie ropes; and conveying, washing and drying the finished object.

Owner:GRAND TEXTILE

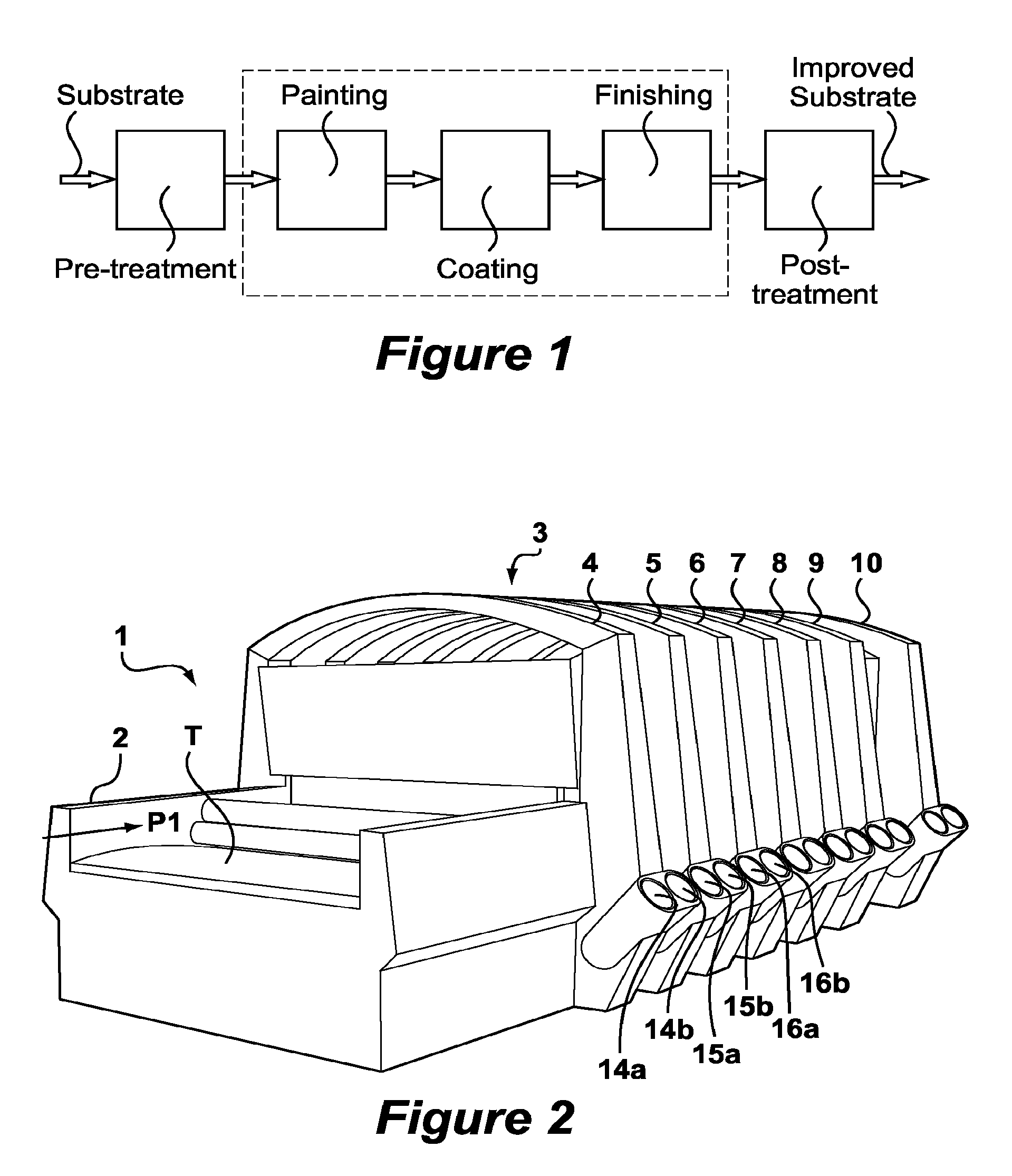

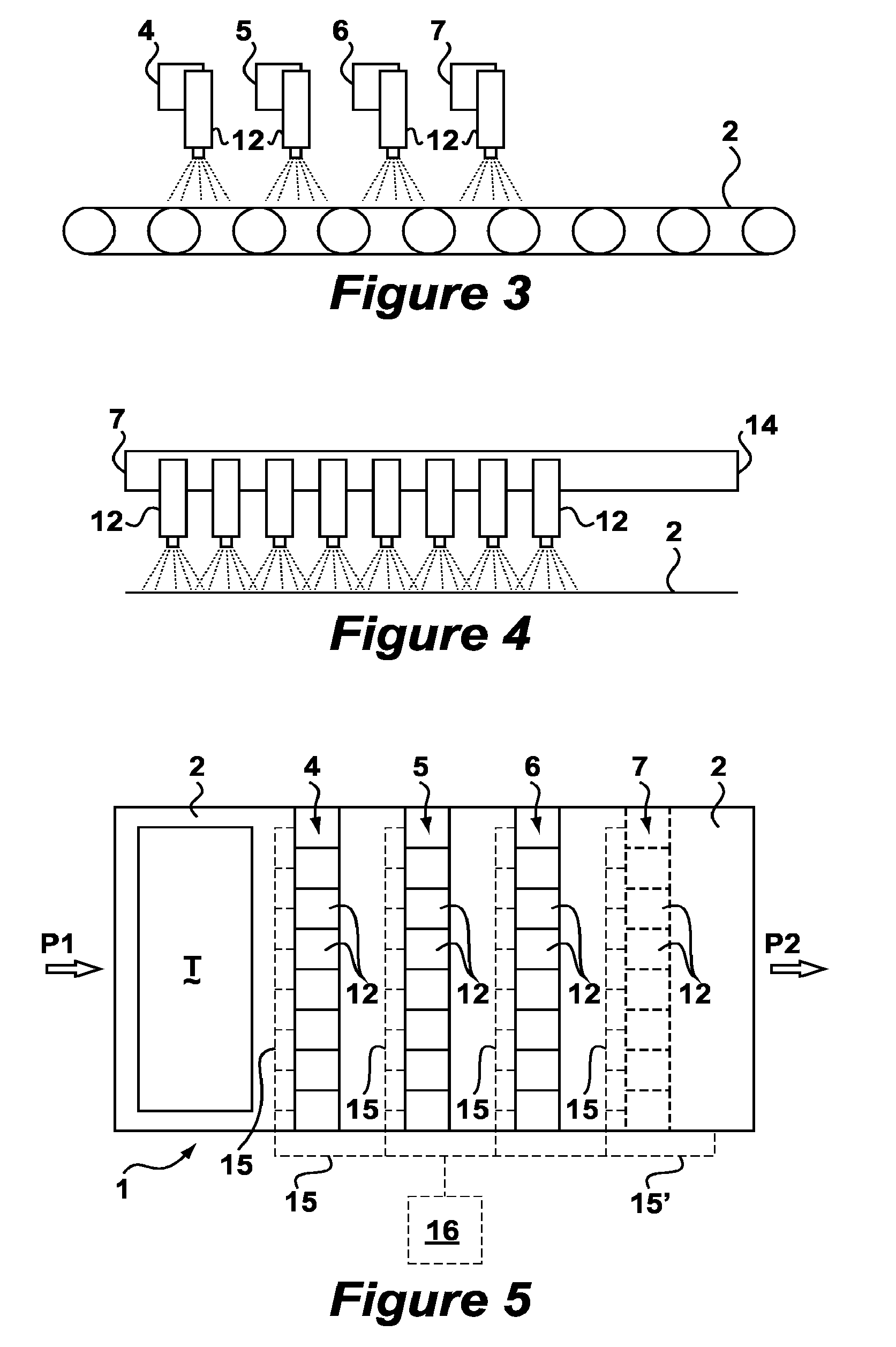

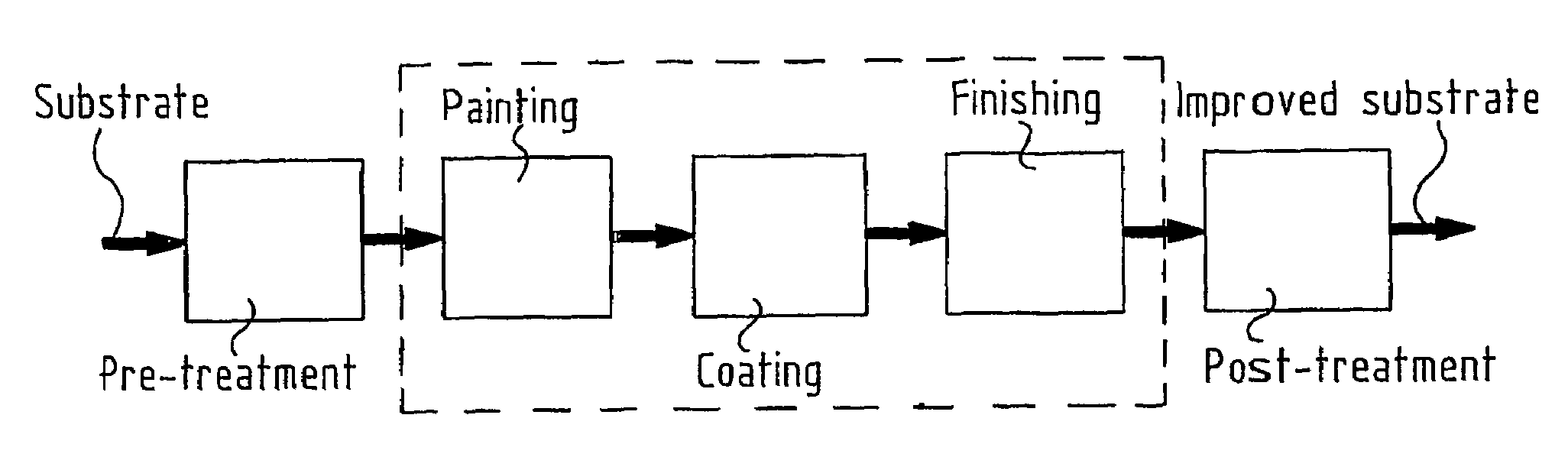

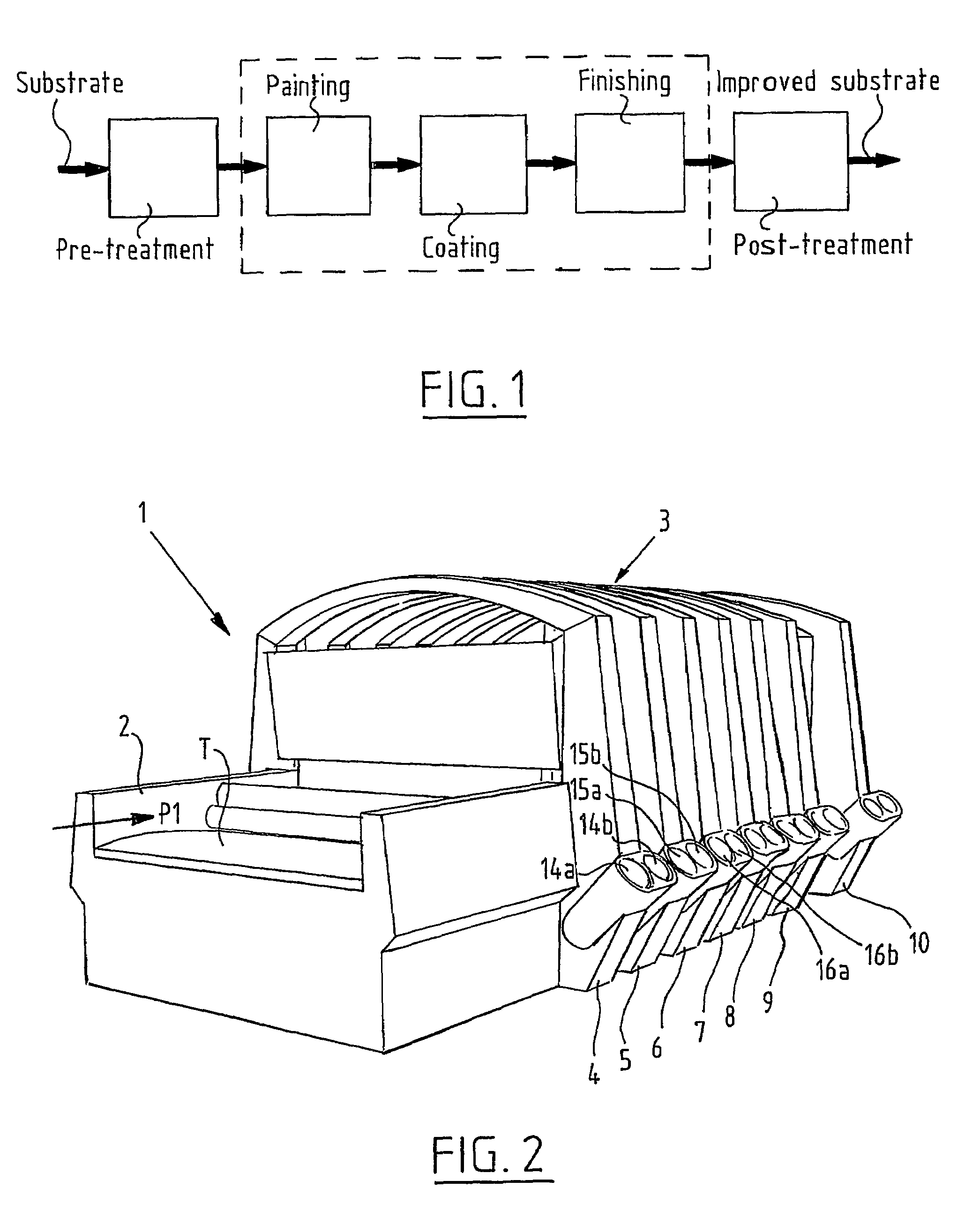

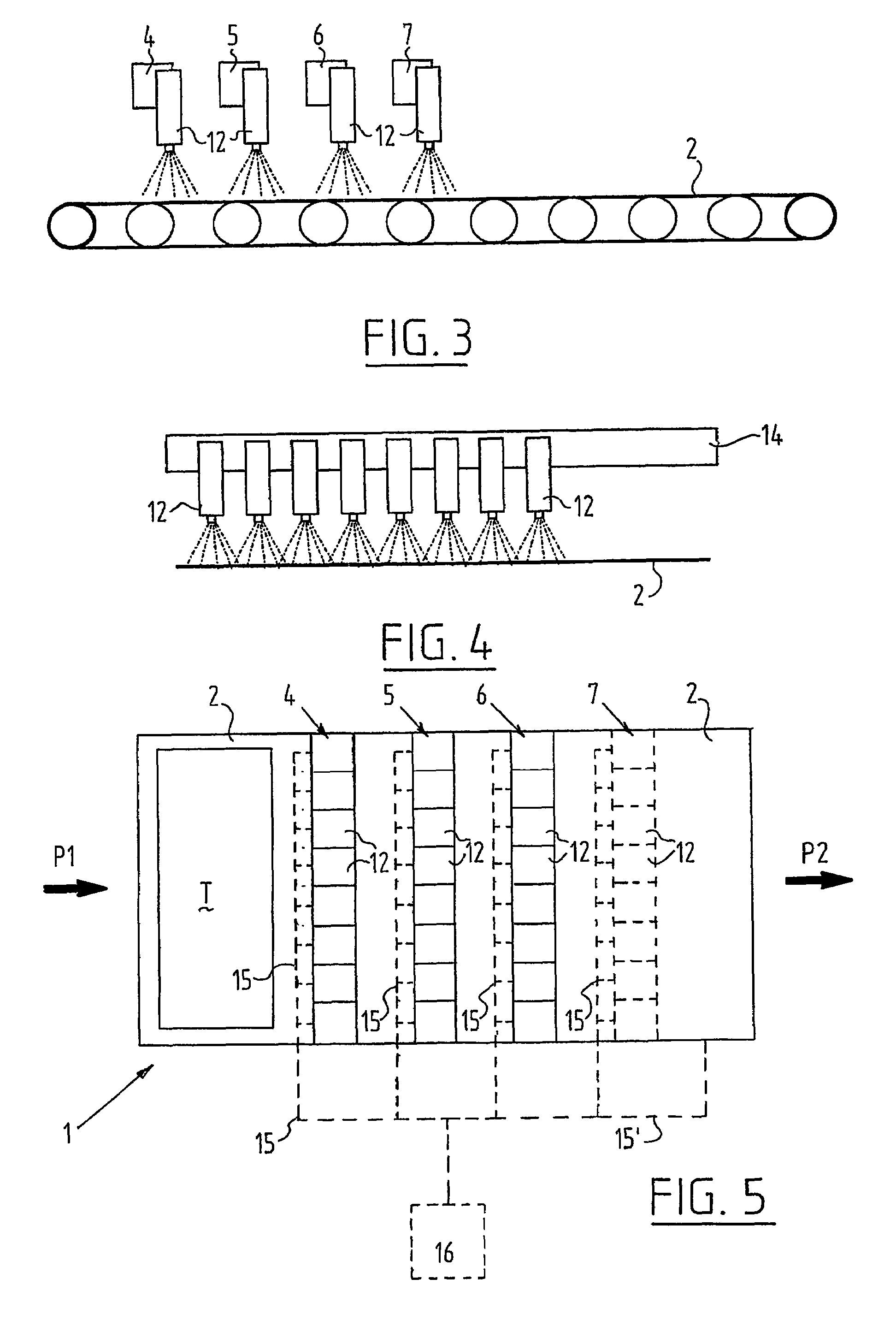

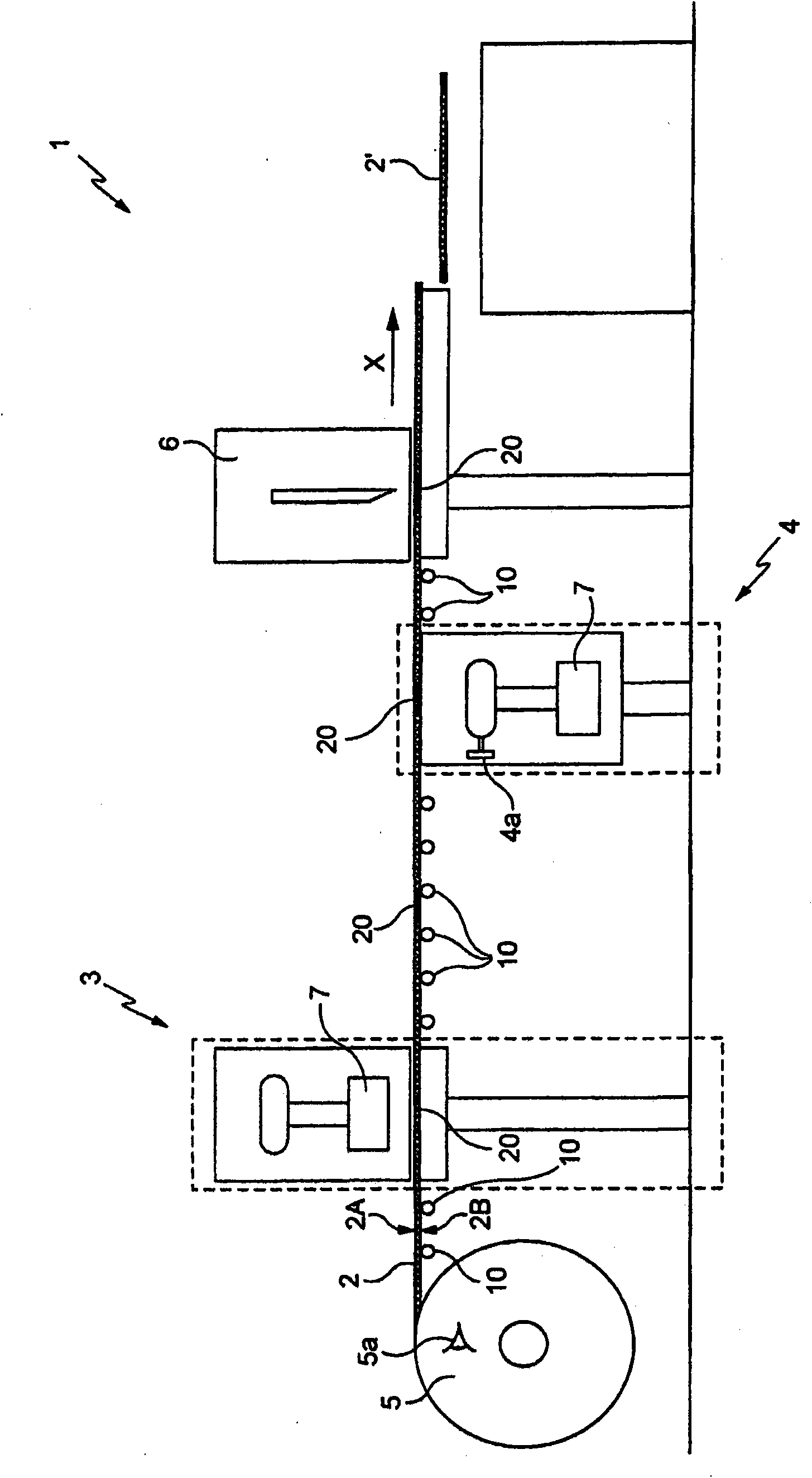

Method and device for digitally upgrading textile

InactiveUS7559954B2Efficient processingForming accuratelySucessive textile treatmentsTextile treatment machine partsEngineeringCoating

The invention provides a method for digitally upgrading a textile article (T) using a textile upgrading device (1), the device (1) comprising a number of nozzles (12) for applying one or more substances to the textile (T), in addition to transport means (2) for transporting the textile (T) along the nozzles (12), wherein the nozzles (12) are ordered in a number of successively placed rows (4, 5, 6, 7) extending transversely of the transporting direction of the textile article (T), the method comprising the steps of: guiding the textile article (T) along a first row (4) of nozzles (12); performing with the first row (4) of nozzles (12) one of the operations of painting, coating or finishing of the textile article (T) carried therealong; subsequently guiding the textile (T) along a second row (5) of nozzles (12); and performing with the second row (5) of nozzles (12) another of the operations of painting, coating or finishing of the textile article (T) carried therealong.

Owner:TEN CATE ADVANCED TEXTILES BV

Mannequin for the surface treatment of trousers

ActiveUS20190142092A1Simple designExtension of timePattern makingLaser beam fibre treatmentEngineeringIntermediate point

Mannequin for the surface treatment of pants. Mannequin for the surface treatment of pants, comprising an upper support structure from which two legs extend, wherein each of said legs has an inflatable balloon arranged at its rear part. Each of said inflatable balloons has its outer lateral section folded upon itself at least once around a folding line extending from the upper edge to the lower edge of the balloon. The upper edge is fixed to the rear upper end of the corresponding leg and the lower edge is fixed to a rear intermediate point of the corresponding leg, such that the parts of the edges corresponding to the outer lateral section are also fixed to the leg of the mannequin.

Owner:JEANOLOGIA

Method for applying an elastomer on a sheath

ActiveCN101796236AAccurate depositionAvoid overdoseRotary pressesPipe protection against damage/wearElastomerPad printing

The invention relates to a method for applying an elastomer on a sheath (2) that comprises the step of applying by pad printing an elastomer layer on a portion (20) of the sheath (2). A pad printing machine (1) is also provided for implementing said method. The invention can particularly be used for textile sheath used in the protection of exhaust-gas circulation pipes in an automobile.

Owner:FEDERAL MOGUL SYST PROTECTION

Customer-Created Textiles and Customer-Oriented Garment Dyeing Machine

InactiveUS20100170049A1Enhance educational and education experienceProcess stabilityTextile treatment containersLiquid/gas/vapor article treatmentYarnEngineering

Customers obtain customized textile materials by selecting style, shape, size, pattern and color for an undyed textile product. Based on a selection made by the customer, the textile product is transformed by a dyeing operation performed on a single item to yield a product, such as a shirt, pants, or jacket which has a color and pattern of his or her own choosing, in the size and style he or she desires. The process can be performed in a retail setting using a dye machine which allows the process to be viewed by the customer. Preferably, the textile material is constructed from yarns which include cationic cotton alone or in combination with natural cotton or other natural or synthetic fibers, and using anionic dyes, such as a fiber reactive dye, such that the dye is exhausted during the process and effluent from the dye machine is environmentally friendly without excess dye, salts, and alkalis. To enhance the educational and entertainment experience of the customer, the dyeing operation can be performed in a transparent tank or water kettle in the retail outlet so that the customer can view, for example, the garment as it is being dyed to the customer's specifications.

Owner:PIANA ANDREA +3

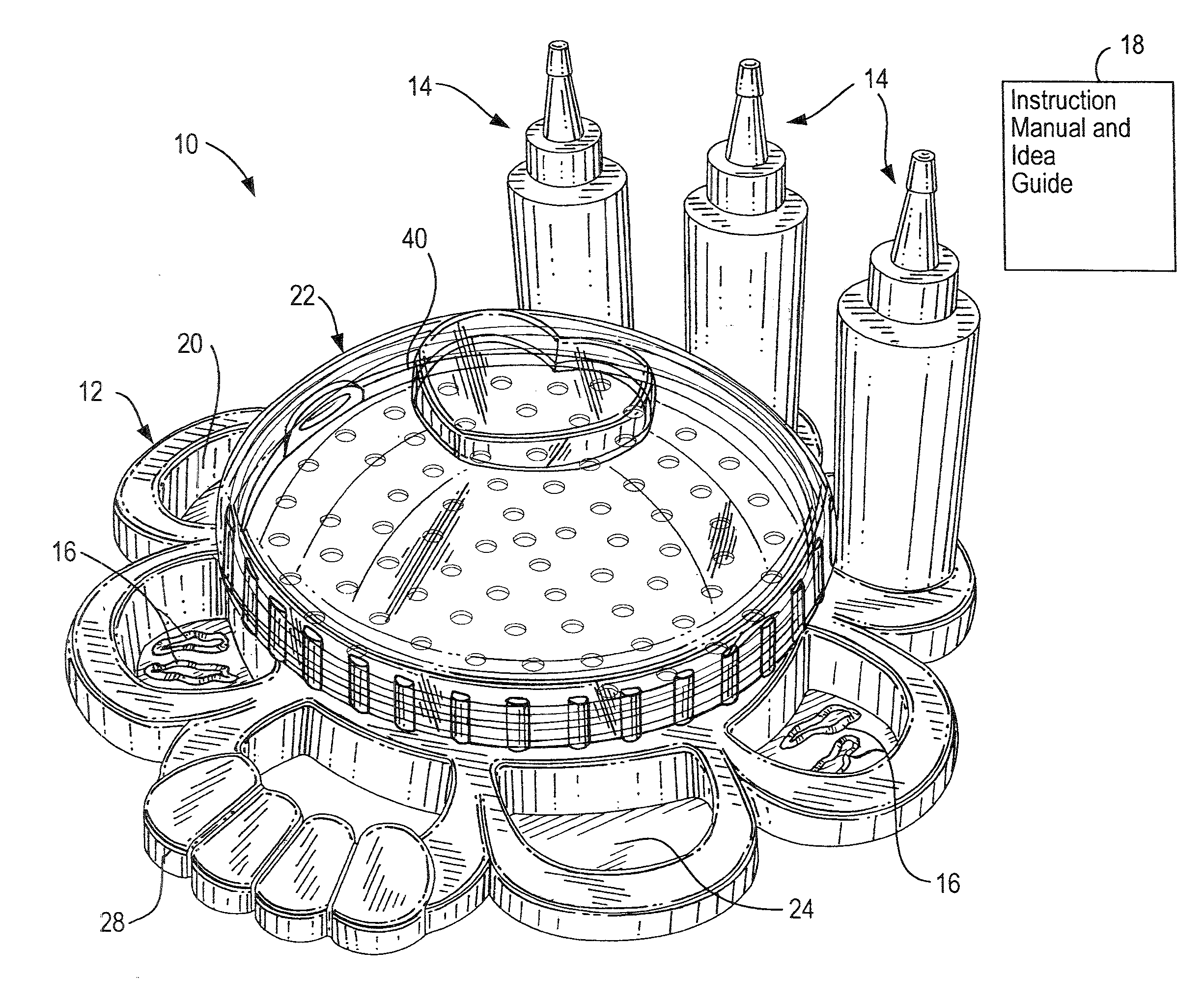

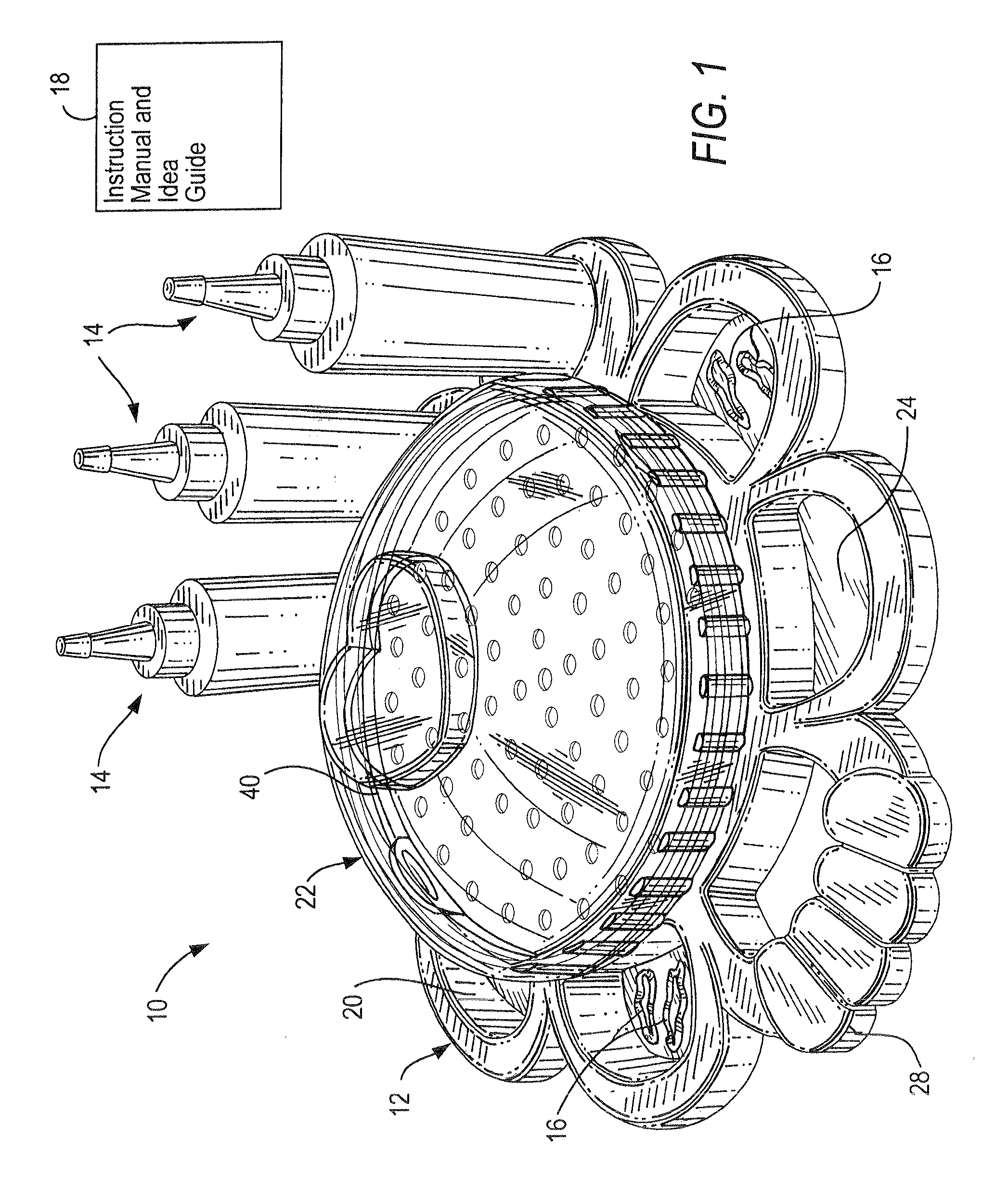

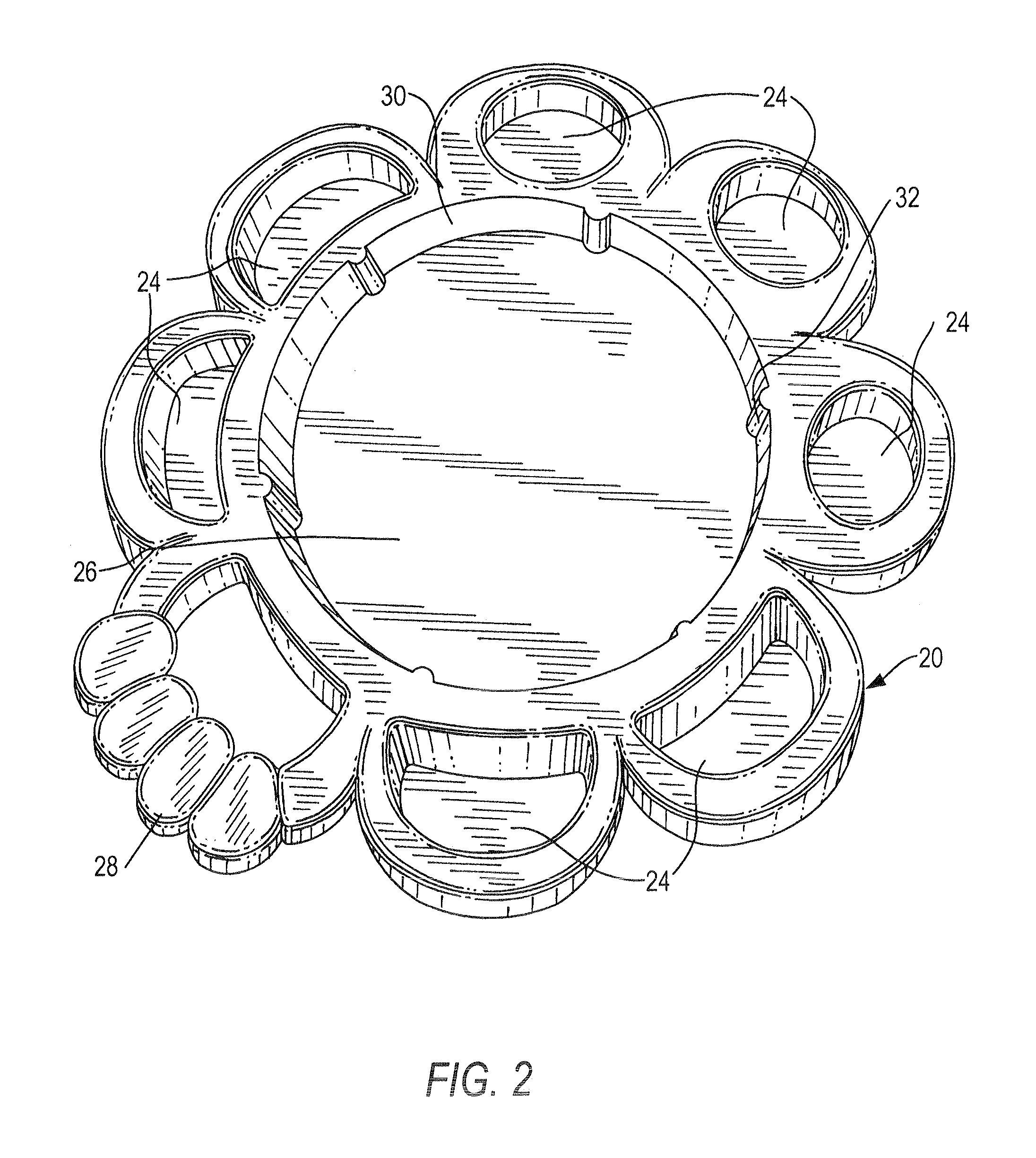

Kit and method for tie-dyeing and utensil therefor

InactiveUS20130055509A1Easy to separateEasily separated from base and cleanedTextile treatment containersHand rubbing apparatusBiomedical engineeringSupport surface

Kit for tie-dyeing an object includes a utensil that retains the object, at least one container of dyeing material, at least one device for maintaining a gathered portion of the object together, and an optional instruction manual or idea guide. The utensil includes a base that can retain the dye containers and devices and an insert arranged in connection with the base. The insert is used during the tie-dyeing and includes a grate elevated from a bottom of the insert, defined by a bottom part, and having a plurality of apertures. The grate forms a support surface for the object and enables dye to flow through the apertures onto the bottom of the insert. The grate can be separated from the bottom part for cleaning and the bottom part can be removed from the base for cleaning.

Owner:HORIZON GROUP USA

Denim clothing monkey processing system and method thereof for coloring denim clothing surfaces

InactiveCN107829239AReduce harmDyeing processTextile treatment by spraying/projectingPower flowDenim

The invention discloses a denim clothing monkey processing system. The system comprises a monkey machine, a flexible PCB circuit band is arranged on the surface of a rubber airbag of the monkey machine, and the lower portion of the monkey machine is provided with potassium permanganate powders; and the invention also discloses a method for coloring denim clothing surfaces, according to color requirements of various parts, different electric current signals are delivered to a designated position through a computer transmission device, different components of the potassium permanganate powders are attracted to the surface of fabrics through different electric current effects and attracting effects, and the denim clothing surfaces are colored through the potassium permanganate powders adsorbed by the electric currents so as to accurately control the depth of patterns and colors.

Owner:WUYI UNIV

Ready-made cowboy clothing monkey processing system with accurate digital processing functions

PendingCN107604552AReduce harmTextile treatment machine arrangementsTextile treatment by spraying/projectingEngineeringPrinted circuit board

Owner:JIANGMEN POLYTECHNIC

Dye applicator for dyeing articles, a dye application kit, and a method for manufacturing the same

ActiveUS20190106824A1Avoid saturationTextile treatment containersDyeing processWater solubleEngineering

A dye applicator for dyeing materials, a dye application kit, and a method for manufacturing the same are provided. The dye application kit has at least one container containing a dye applicator being at least partially fibrous and infused with a dry water-soluble dye, the dye being transferrable to an adjacent article in the presence of water

Owner:SPIN MASTER LTD

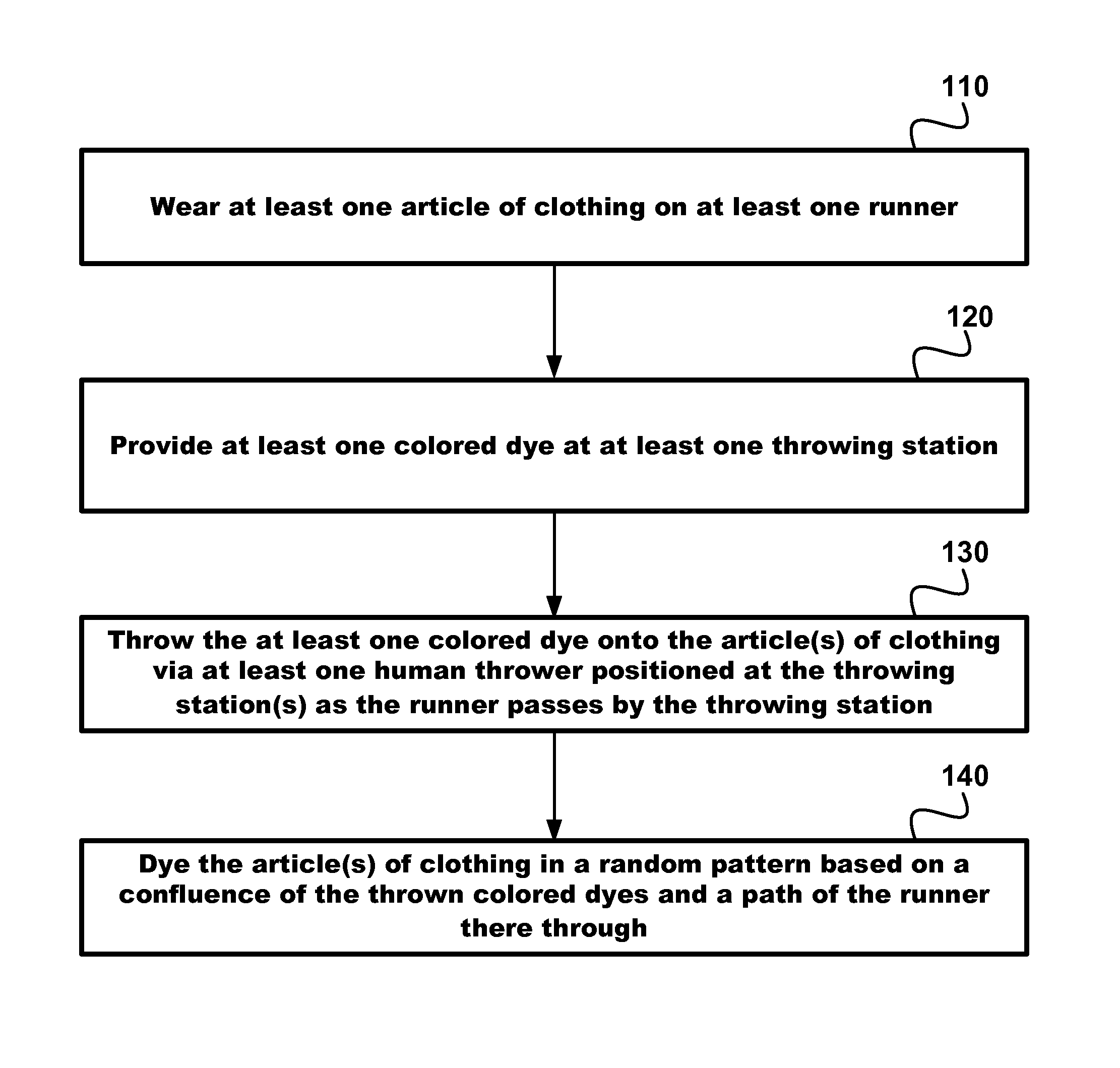

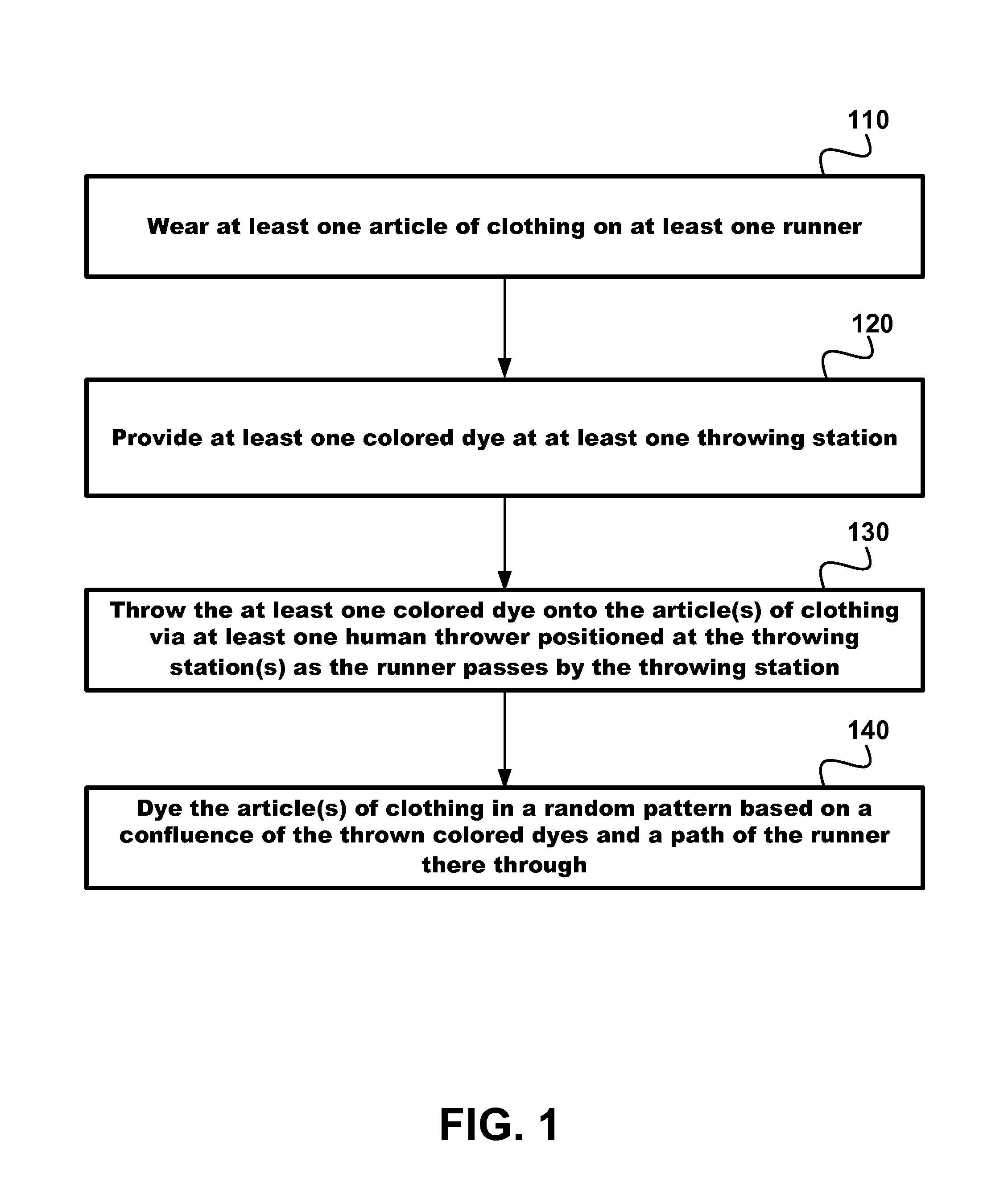

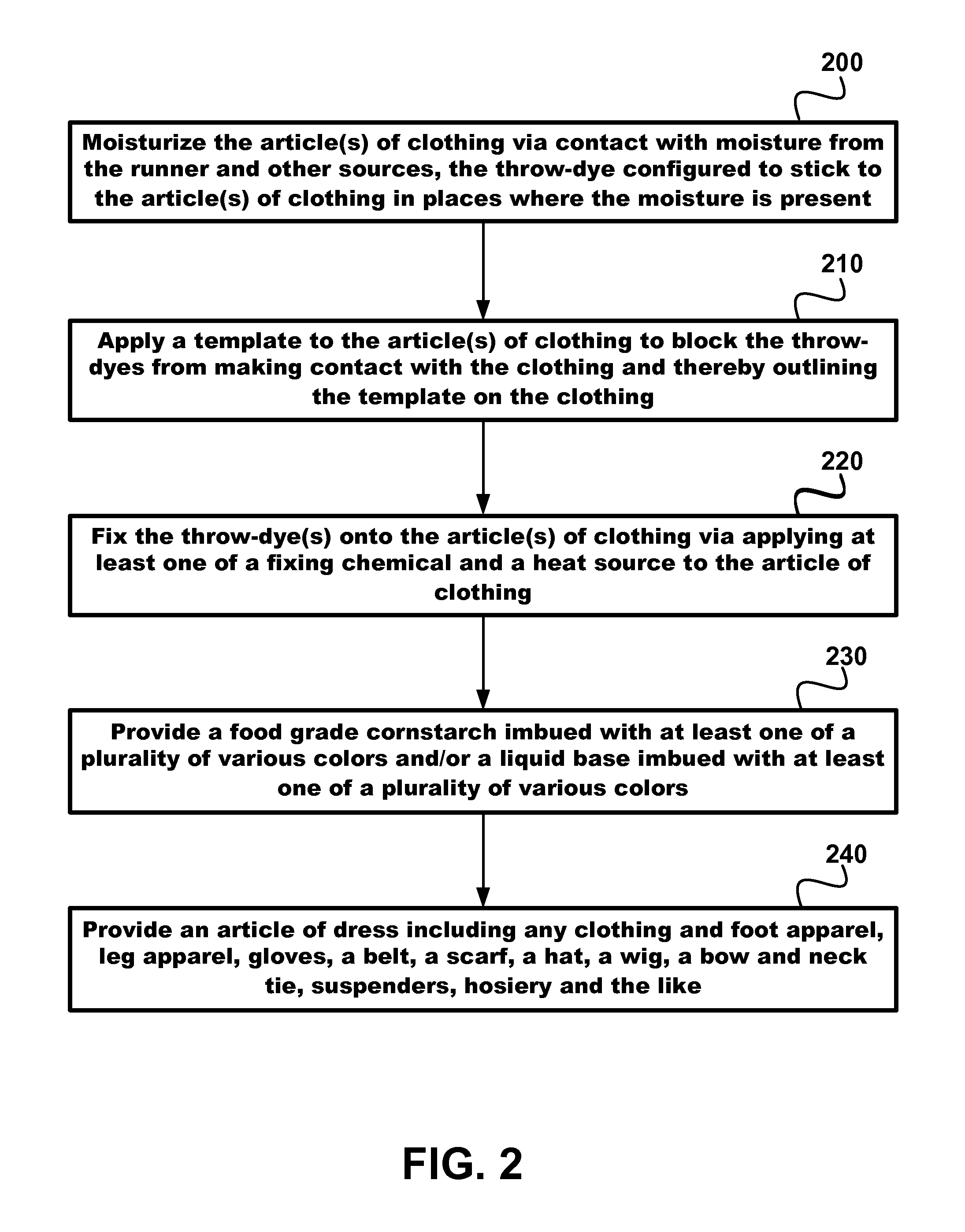

Toss-dye random clothing design system and method

As disclosed, a toss-dye random clothing design system and method comprises at least one article of clothing worn by a runner at a race, a sporting event, a corporate or collegiate event, a fashion party, a production plant shift and the like, a plurality of colored dyes provided at a plurality of throwing stations, at least one thrower positioned at a throwing station to throw the dyes onto the clothing as the runner passes by the throwing station, and a random pattern of throw-dye on the clothing based on a confluence of the thrown colored dyes and a path the runner takes there through. Embodiments of the disclosure may include a throw-dye configured to stick to the clothing article(s) in places where moisture is present and a template configured to block the thrown dyes from making contact with the clothing and thereby outline a corporate or collegiate logo thereon.

Owner:ACKERMAN JAKE

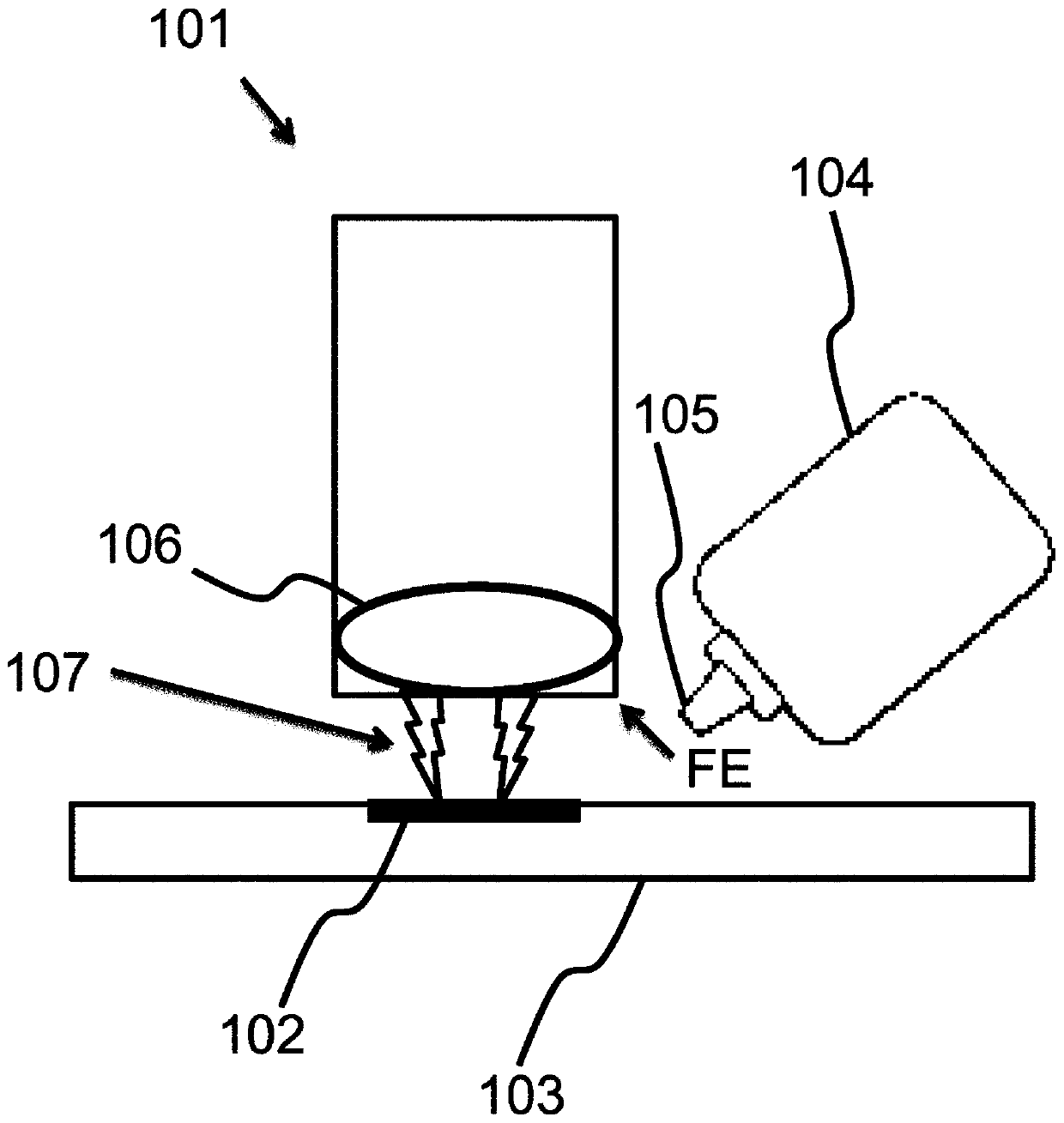

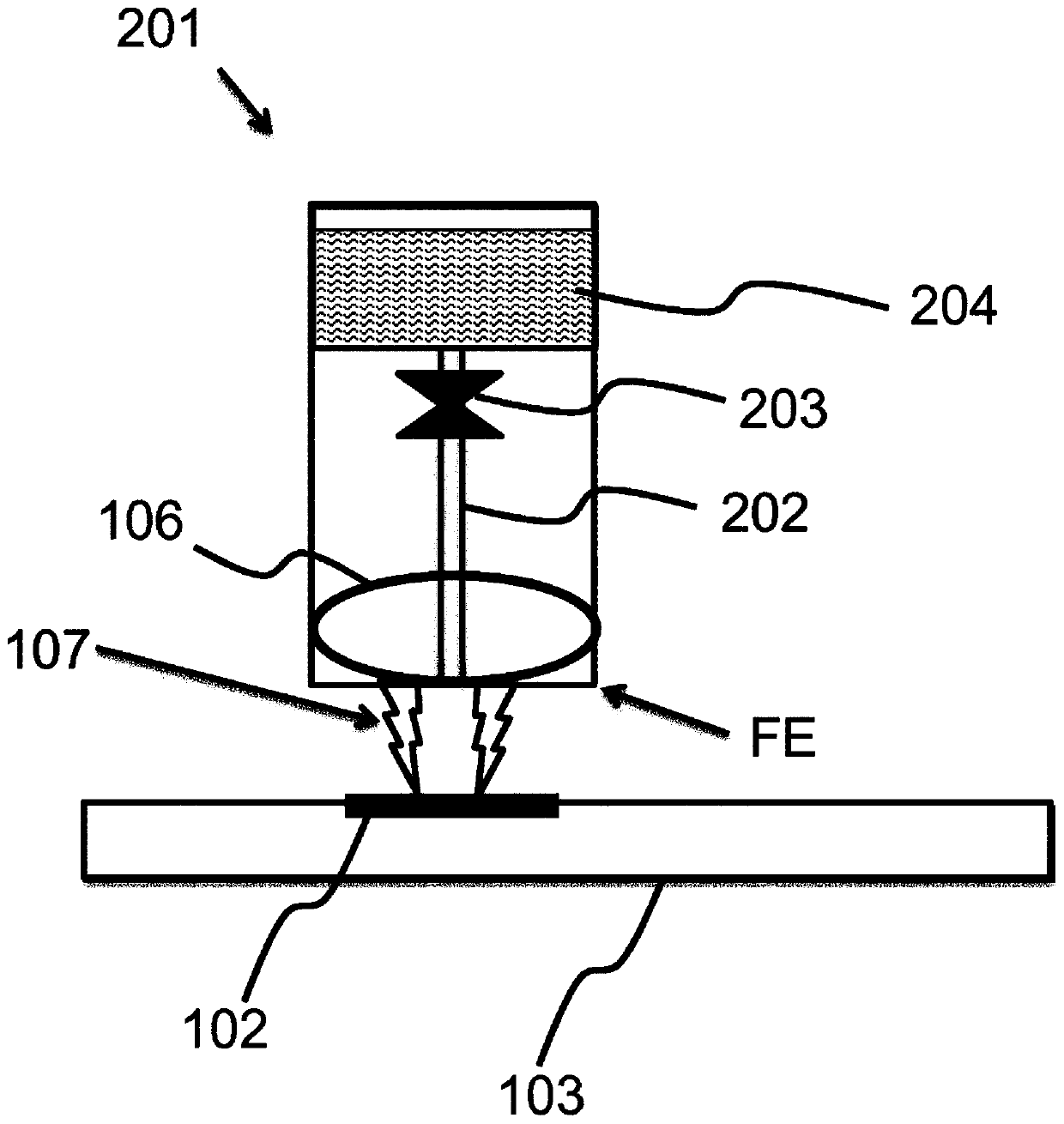

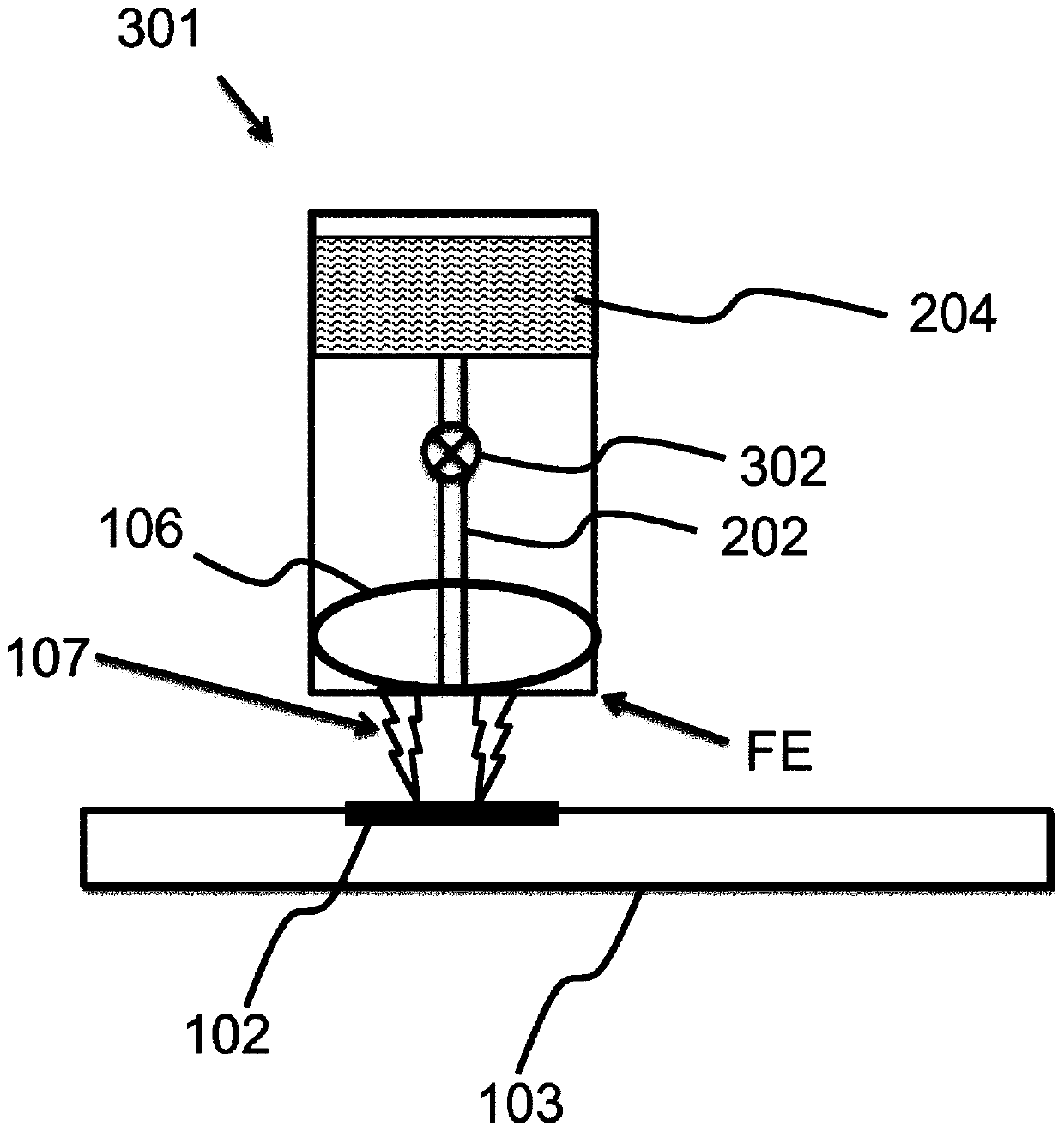

Light-promoted stain removal system

ActiveCN111032951AReduce weightCompact designDry-cleaning apparatusHousehold cleanersOptical radiationMedicine

Stain removal system (101) for treating a stained area (102) on a cloth (103), said stain removal system (101) comprises a container (104) for containing a bleach chemical, wherein the container (104)is a removable cartridge, a system (105) for carrying the bleach chemical to the stained area under a liquid form, and a light source (106) for generating light radiation (107) over the stained area(102).

Owner:范颂尼控股有限公司

Automatically color mix dyeing process

ActiveUS10337143B2Increase productionOrnamental textile articlesKnottingEngineeringMechanical engineering

An automatic color mix dyeing process includes activating an automatic shaping device to shape an undyed object as a cylinder and tightening same; conveying the undyed object to a dyeing apparatus by means of spraying wherein the dyeing apparatus includes rows of spray devices, dye containers for containing dyes of different colors, each dye container being in fluid communication with the row of spray devices, a pump for moving the dyes in the dye containers to the rows of spray devices, and a control device for controlling the rows of spray devices to control a spray sequence, a spray time, and a spray quantity of dye; conveying the dyed object from the dyeing apparatus to a vapor device for color fixing wherein the dyed object is impregnated with hot vapor to obtain a finished object; cutting the tie ropes; and conveying, washing and drying the finished object.

Owner:GRAND TEXTILE

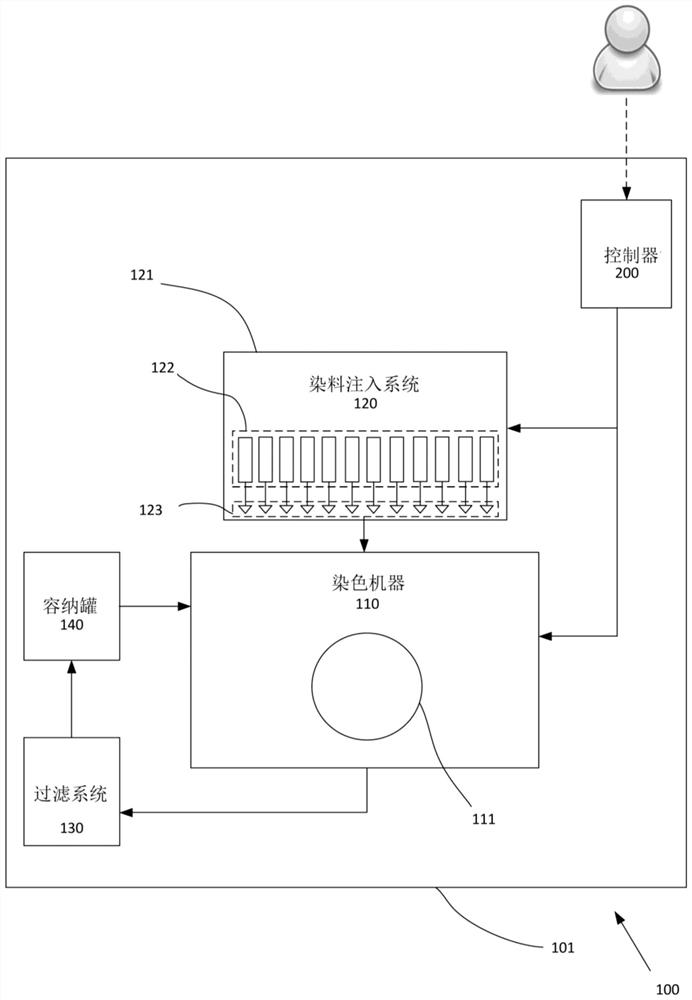

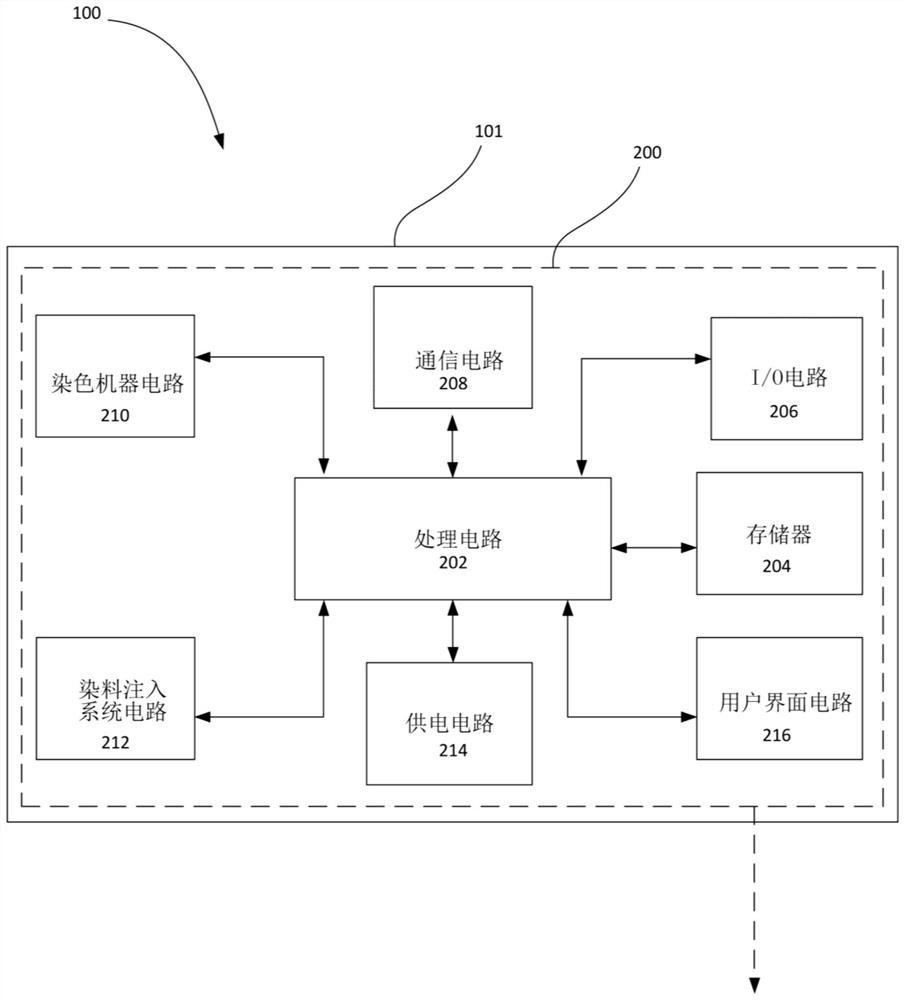

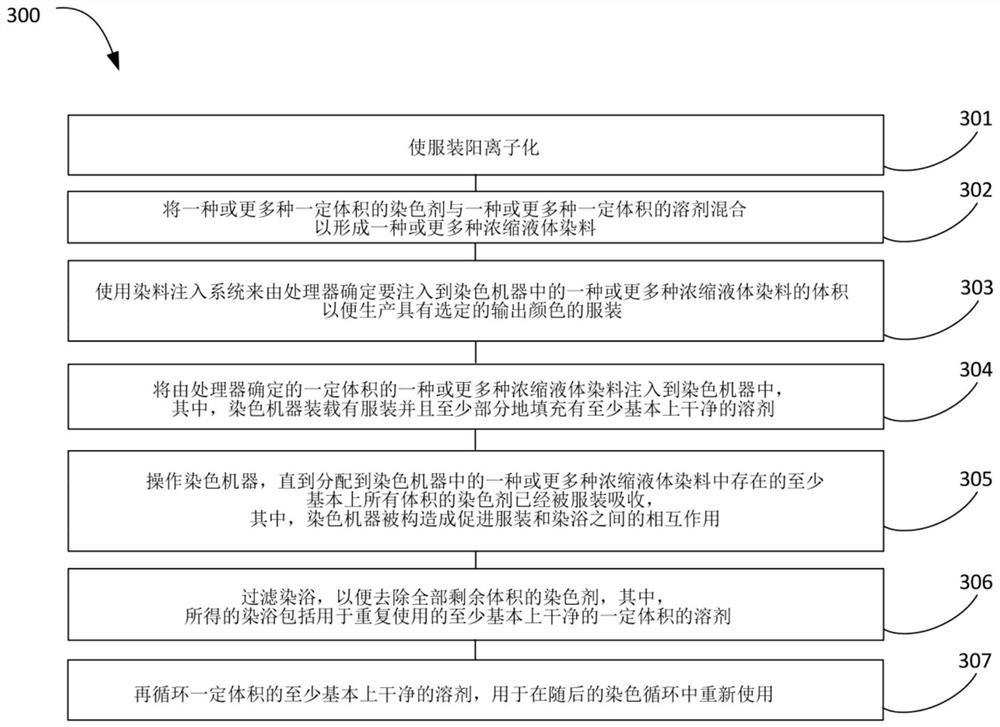

Method and apparatus for dyeing garments

PendingCN114026280ALiquid/gas/vapor treatment of propelled fabricsComputer controlProcess engineeringIndustrial engineering

Described herein are apparatuses and methods for dyeing garments. An exemplary apparatus comprises a dye injection system configured to dispense concentrated liquid dye; a dyeing machine comprising a dyeing chamber configured for dyeing at least one garment in a dyebath; and a controller in communication with the dye injection system and the dyeing machine, wherein the controller is configured: to receive at least one garment parameter corresponding to the at least one garment; based at least in part on the at least one received garment parameter, cause the dye injection system to dispense a volume of concentrated liquid dye containing an amount of dyestuff that can be substantially absorbed by the at least one garment; and cause the dyeing machine to execute a dye cycle such that substantially all of the dyestuff in the dispensed concentrated liquid dye is absorbed by the at least one garment within the dyeing chamber.

Owner:랄프로렌코포레이션

Dyeing process of jean fabric

InactiveCN107747174AImprove aestheticsSimplify production stepsLiquid/gas/vapor article treatmentLiquid/gas/vapor removalEngineeringDyeing

The invention discloses a dyeing process of a jean fabric. The dyeing process comprises the following steps that firstly, a dye is prepared; secondly, sample cloth is subjected to trial dyeing and comparison; thirdly, pre-dyeing pretreatment is carried out; fourthly, the dye and water are added to a dye vat and a to-be-dyed garment is added; fifthly, an additive is added, and heating and stirringare conducted; sixthly, water reducing and drying are conducted; seventhly, washing and airing are conducted; eighthly, the ready-to-wear garment is finished. The technical steps of the dyeing processare simple, the production cost is low, mass production is easy, the efficiency is high, and the attractiveness of the garment is good.

Owner:FANCHANG QINGXIN WASHING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com