Customer-Created Textiles and Customer-Oriented Garment Dyeing Machine

a technology of customer-created textiles and dyeing machines, applied in the direction of dyeing process, textile treatment by spraying/projecting, article parts treatment, etc., can solve the problems of not being able to obtain the garment in the color, pattern, faded, etc., he or she wants, etc., to enhance the educational and educational experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example i

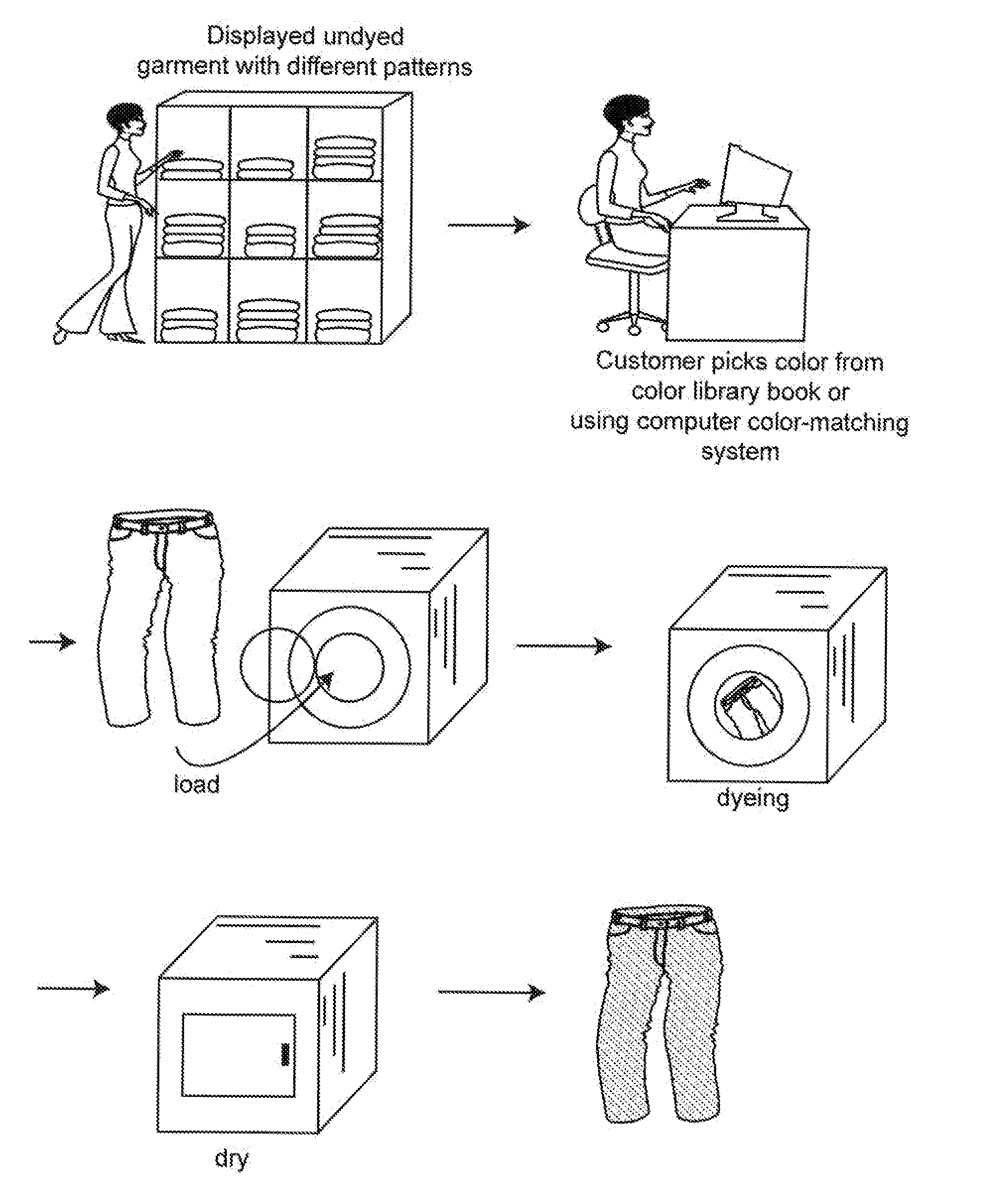

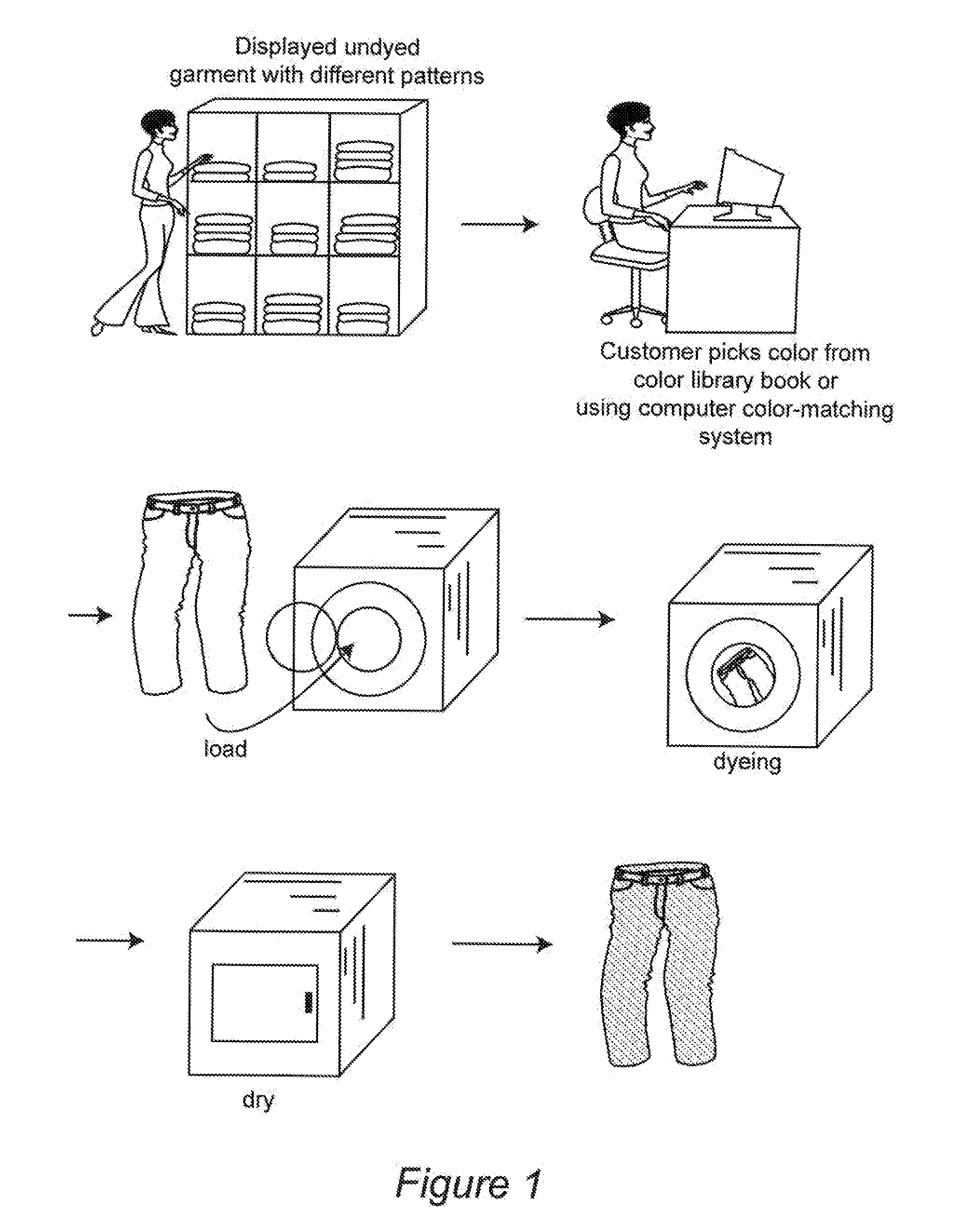

[0029]A customer chooses an undyed knit shirt having stripes made from cotton yarns containing different levels of cationic cotton. The customer chooses a red color. The shirt is loaded in a garment dyeing machine. Predissolved red fiber-reactive dye (1% on weight of garment) is added to the machine at the liquor to goods ratio of 15:1. The dyeing bath is heated to 180 F and run for 10 min. The bath was cooled, drained, rinsed with warm water, and extracted. The dyed garment was dried using a commercial drier. The final dyed shirt is obtained with red stripes with shade gradations.

example ii

[0030]A customer chooses undyed pants woven with cationic cotton yarn as warp and natural cotton yarn as filling. The customer chooses a blue color. The pants are loaded in a garment dyeing machine. Predissolved blue fiber-reactive dye (2% on weight of garment) is added to the machine at the liquor to goods ratio of 15:1. The dyeing bath was heated to 180 F and run for 15 min. The bath was cooled, drained, rinsed with warm water, and extracted. The dyed garment was dried using a commercial drier. The final dyed pants are obtained with blue jean look.

example iii

[0031]A customer chooses an undyed knit shirt made with cotton yarn containing 100% cationic cotton. The customer chooses a blue color. The shirt is loaded in a garment dyeing machine. Predissolved blue fiber-reactive dye (1% on weight of garment) is added to the machine at the liquor to goods ratio of 15:1. The dyeing bath was heated to 180 F and run for 10 min. The bath was cooled, drained, rinsed with warm water, and extracted. The dyed garment was dried using a commercial drier. The final dyed shirt is obtained with solid blue color.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| color | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com