Method for applying an elastomer on a sheath

An elastomer and elastomer layer technology, applied in the treatment of textile materials, local treatment of textile materials, pipes/pipe joints/pipe fittings, etc., can solve the problem of inaccurate application of elastomers, uneven thickness of elastomer layers, Excessive consumption and other problems to achieve the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

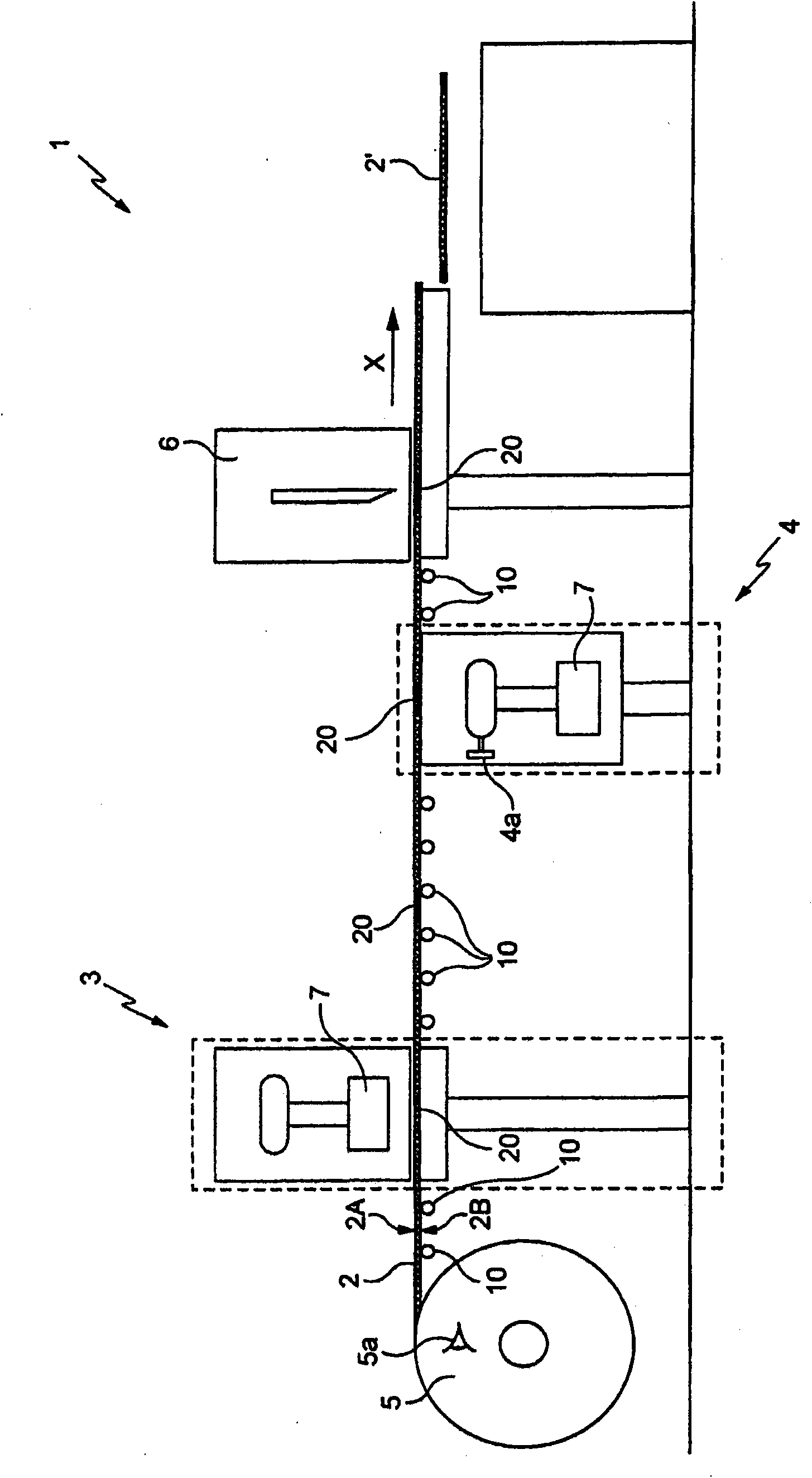

[0059] First refer to figure 1 A pad printer for depositing elastomers on a sleeve of the present invention is described.

[0060] In this embodiment, the method is applied to a tubular fabric kit 2 .

[0061]By way of non-limiting example, this sheath 2 is a fabric sheath knitted from multifilaments of glass fibers impregnated with an acrylic solution containing graphite. Thus, the sheath 2 is flexible and can be crushed.

[0062] Of course, the sleeve 2 can also be manufactured from other materials, such as eg silicon dioxide, ceramics or polymers. In the case of a textile sheath, the sheath can for example consist of knitted, woven or braided multifilaments or monofilaments.

[0063] The flattened kit 2 is transported along the pad printing machine 1 by standard transport means 10 such as, for example, a series of driven rollers.

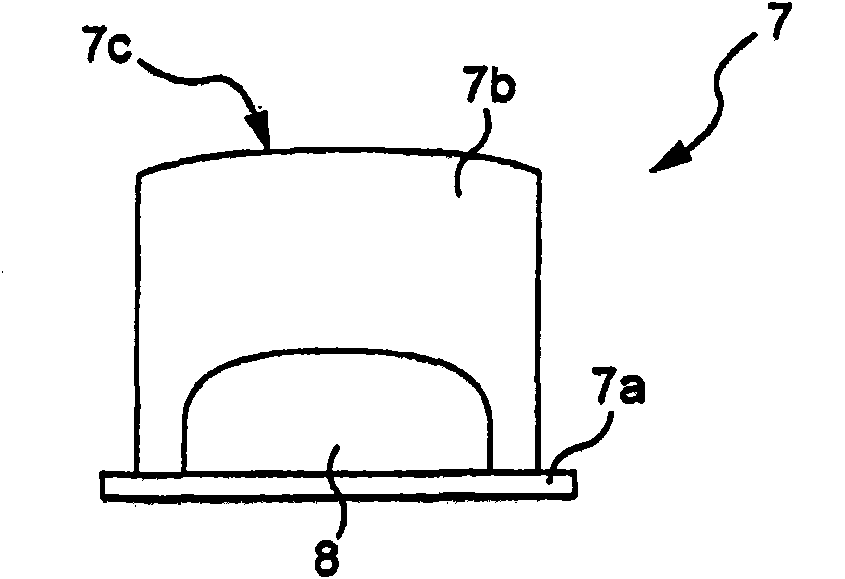

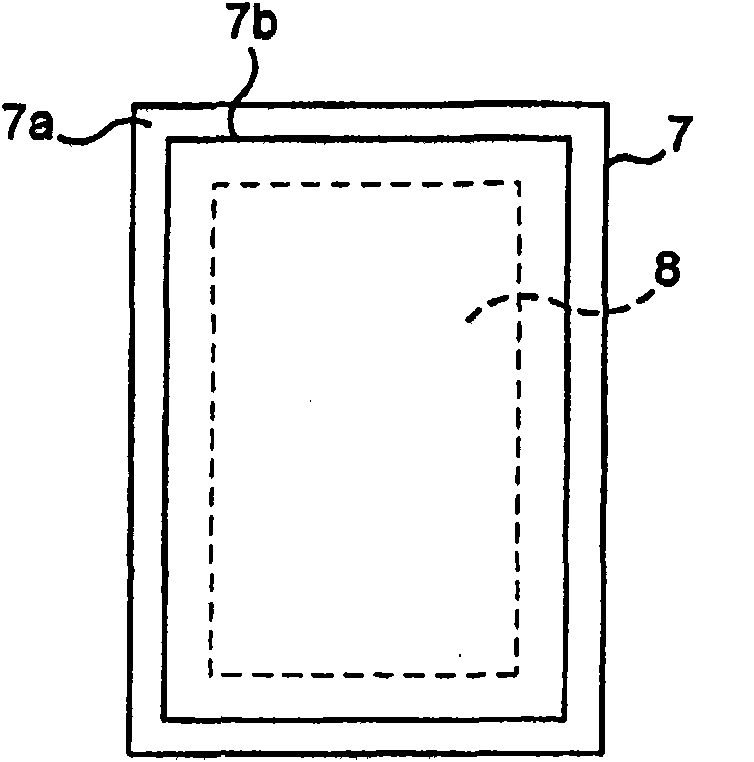

[0064] In this embodiment, the pad printing machine 1 comprises two pad printing modules 3 , 4 . Each pad printing module 3,4 all includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com