a tio 2 Fabrication method of /au/copi composite nanotube array photoanode

A nanotube array, photoanode technology, applied in electrodes, coatings, electrolytic components, etc., can solve the problem of low reaction rate and achieve the effect of increasing active sites, high efficiency and uniform morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A kind of TiO 2 The preparation method of Au / CoPi composite nanotube array photoanode is carried out as follows:

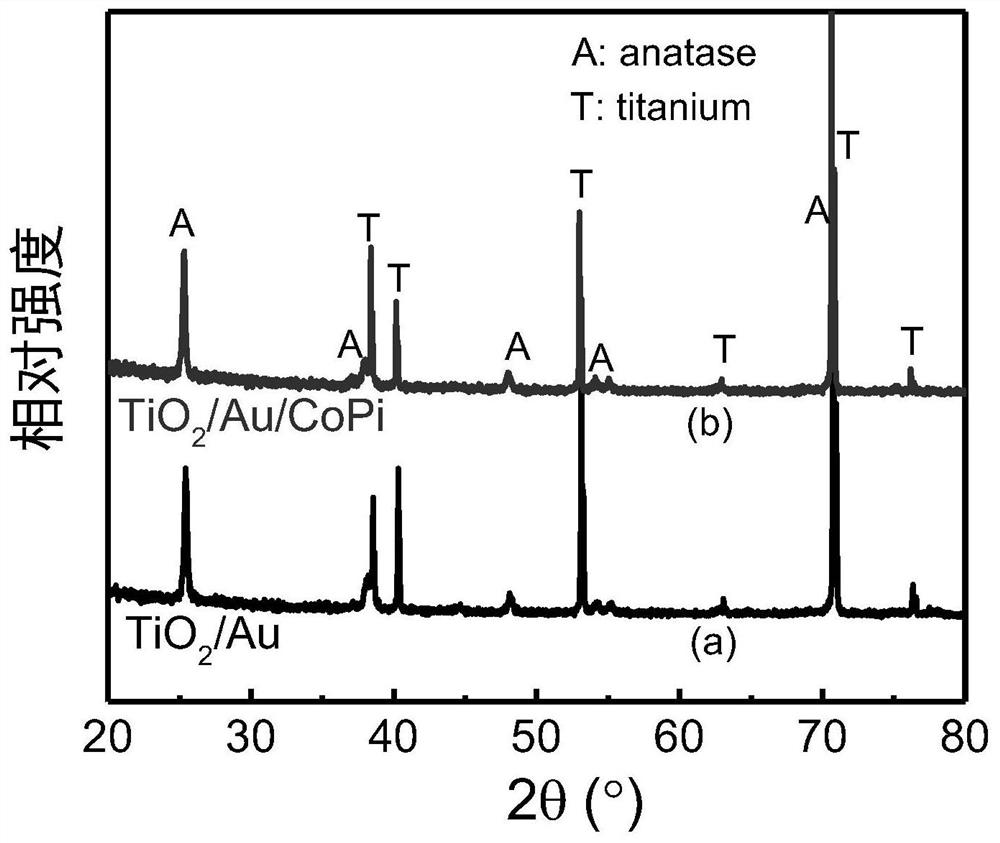

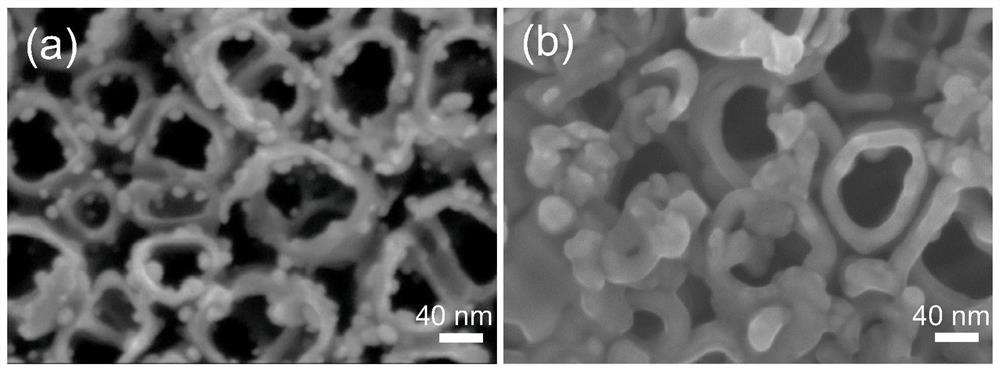

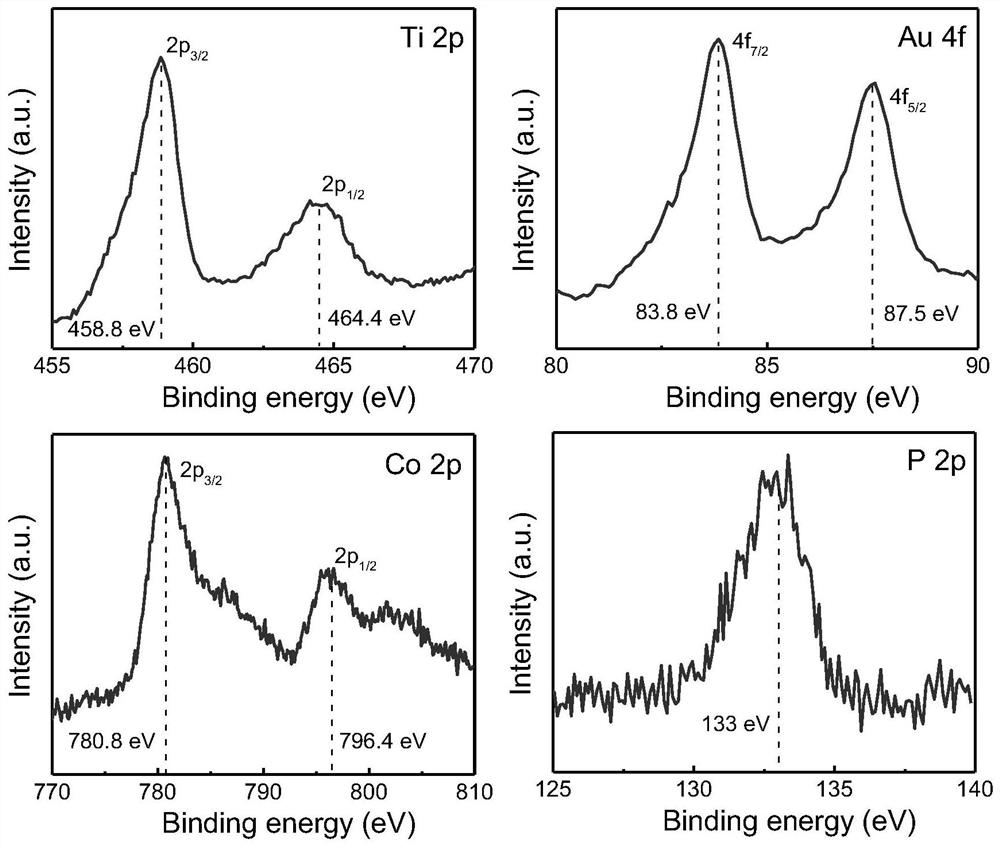

[0033] 1) TiO 2 Fabrication of Nanotube Array Thin Films

[0034] The titanium sheet substrate was pretreated with an equal volume of NH at a concentration of 0.4M 4 F and H at a concentration of 0.2M 3 PO 4 The mixed solution was used as the electrolyte, the Ti sheet was used as the working electrode, and the Pt sheet was used as the counter electrode. Anodization was carried out at a voltage of 20 V for 7 h, and then placed in a muffle furnace for 500 o C roasted for 2 h to obtain anatase TiO 2 nanotube array films;

[0035] 2) TiO 2 / Preparation of Au nanotube array films

[0036] TiO 2 Nanotube arrays in 1 mM HAuCl 4 The solution was ultrasonically treated for 5 min, and then it was used as the working electrode, the Pt sheet was used as the counter electrode, and the Ag / AgCl electrode was used as the reference electrode, and HAuCl with a conc...

Embodiment 2

[0040] A kind of TiO 2 The preparation method of the / Au / CoPi composite nanotube array photoanode is characterized in that it proceeds as follows:

[0041] 1) TiO 2 Fabrication of Nanotube Array Thin Films

[0042] The titanium sheet substrate was pretreated with an equal volume of NH at a concentration of 0.4M 4 F and H at a concentration of 0.2M 3 PO 4 The mixed solution was used as the electrolyte, the Ti sheet was used as the working electrode, and the Pt sheet was used as the counter electrode. Anodization was carried out at a voltage of 20 V for 7 h, and then placed in a muffle furnace for 500 o C roasted for 2 h to obtain anatase TiO 2 nanotube array films;

[0043] 2) TiO 2 / Preparation of Au nanotube array films

[0044] TiO 2 Nanotube arrays in 1 mM HAuCl 4 The solution was sonicated for 6 min, and then it was used as the working electrode, the Pt sheet was used as the counter electrode, and the Ag / AgCl electrode was used as the reference electrode. 4 The ...

Embodiment 3

[0048] A kind of TiO 2 The preparation method of the / Au / CoPi composite nanotube array photoanode is characterized in that it proceeds as follows:

[0049] 1) TiO 2 Fabrication of Nanotube Array Thin Films

[0050] The titanium sheet substrate was pretreated with an equal volume of NH at a concentration of 0.4M 4 F and H at a concentration of 0.2M 3 PO 4 The mixed solution is the electrolyte, the Ti sheet is used as the working electrode, and the Pt sheet is used as the counter electrode. Anodization is carried out at a voltage of 20 V for 7 hours, and then placed in a muffle furnace for 500 o C roasted for 2 h to obtain anatase TiO 2 nanotube array films;

[0051] 2) TiO 2 / Preparation of Au nanotube array films

[0052] The TiO prepared in step 1) 2 nanotube arrays in 1 mM HAuCl 4 The solution was sonicated for 3 min, and then it was used as the working electrode, the Pt sheet was used as the counter electrode, and the Ag / AgCl electrode was used as the reference el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com