Operation table with anti-falling mechanism for attached scaffold

An attached and operating table technology, which is applied to the scaffolding supported by the building structure, the accessories of the scaffolding, and the building structure, etc., can solve the problems of safety hazards, platen falling, etc., to protect the environment, facilitate subsequent use, and avoid corrosion effects on lifespan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

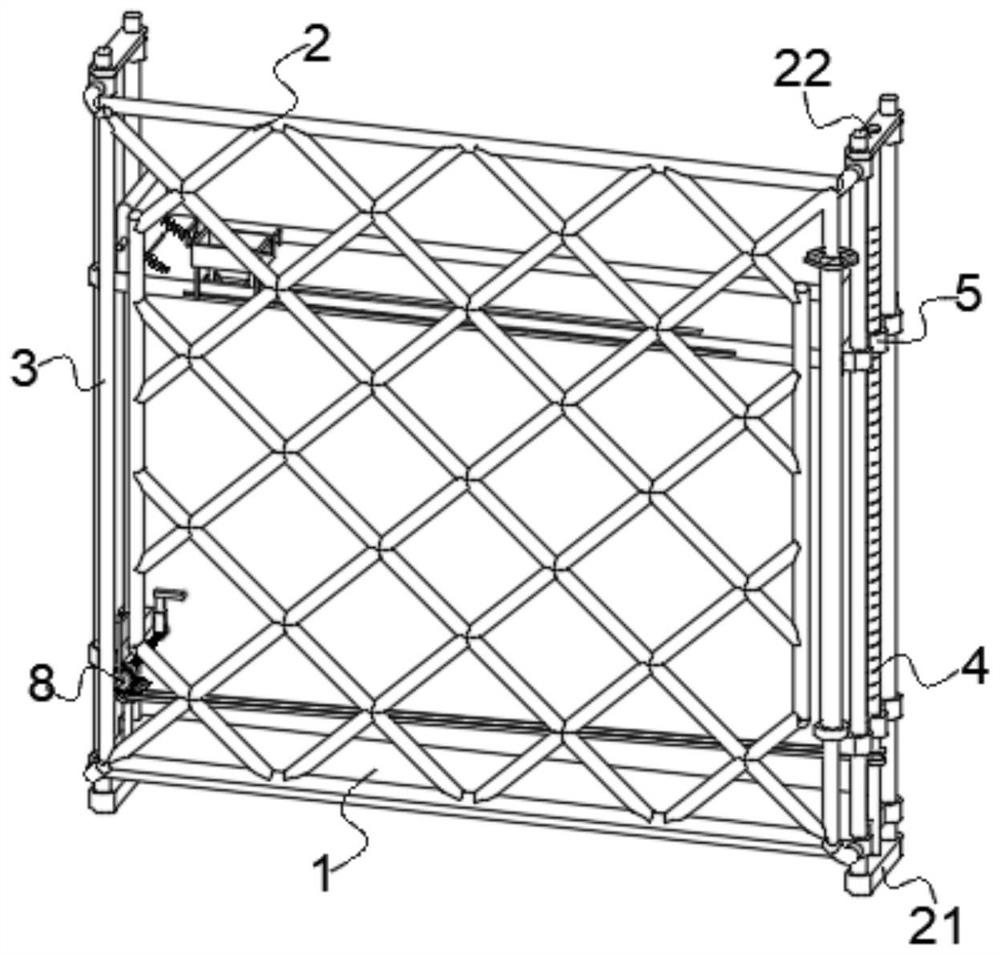

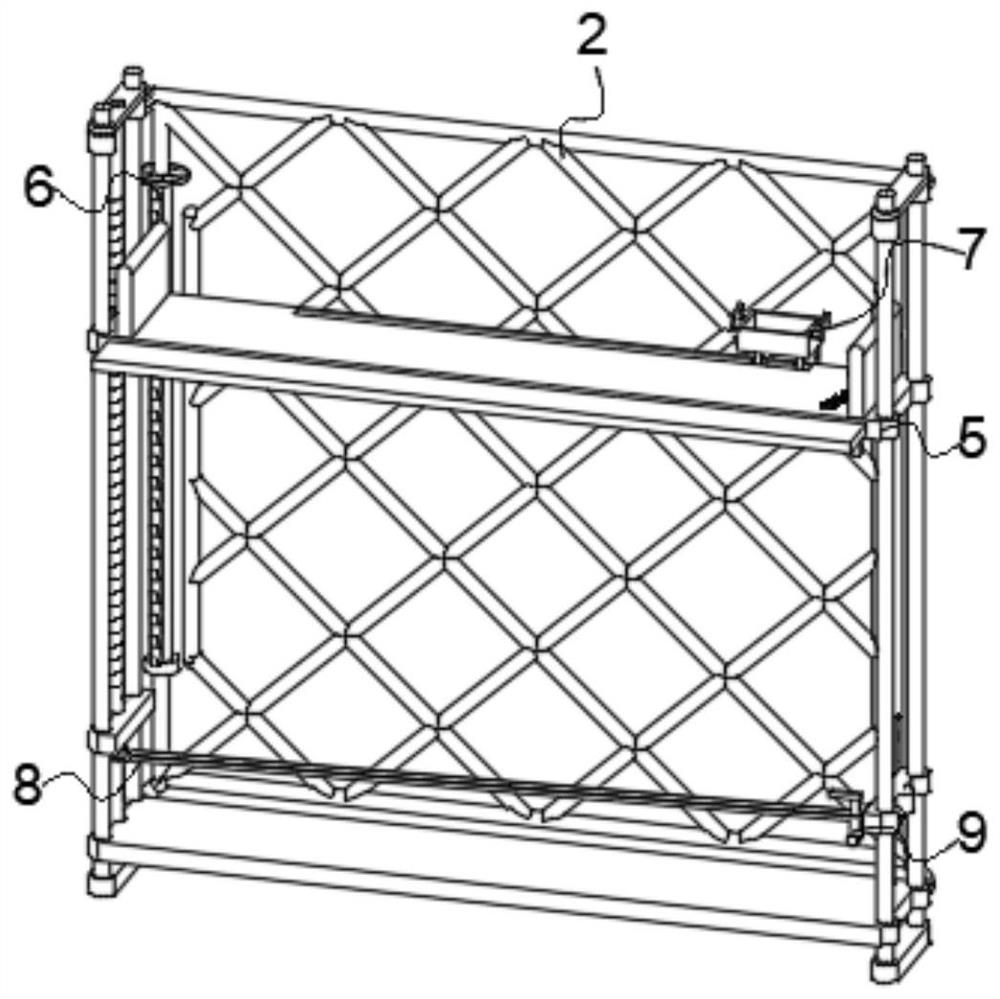

[0044] see Figure 1-Figure 10 As shown, the purpose of this embodiment is to provide an attached scaffolding operating table with an anti-fall mechanism, including at least:

[0045] A support plate 1, an outer rail 2 is installed on the outside of the support plate 1, and the outer rail 2 is composed of multiple groups of rod bodies. The two sides of the outer rail 2 are symmetrically provided with support rods 3, and each group of support rods 3 is at least two, and the support rod 3 A fixed plate 21 is installed at the bottom of the vertical screw rod 4, and a vertical screw rod 4 is arranged on the surface of the fixed plate 21. The bottom of the vertical screw rod 4 can be driven by a motor, and the surface of the vertical screw rod 4 is threadedly connected with an operating table 5. The operating table 5 is used for people to stand or place materials, and the supporting board 1, the outer railing 2, the supporting rod 3, the vertical screw 4 and the operating table 5 f...

Embodiment 2

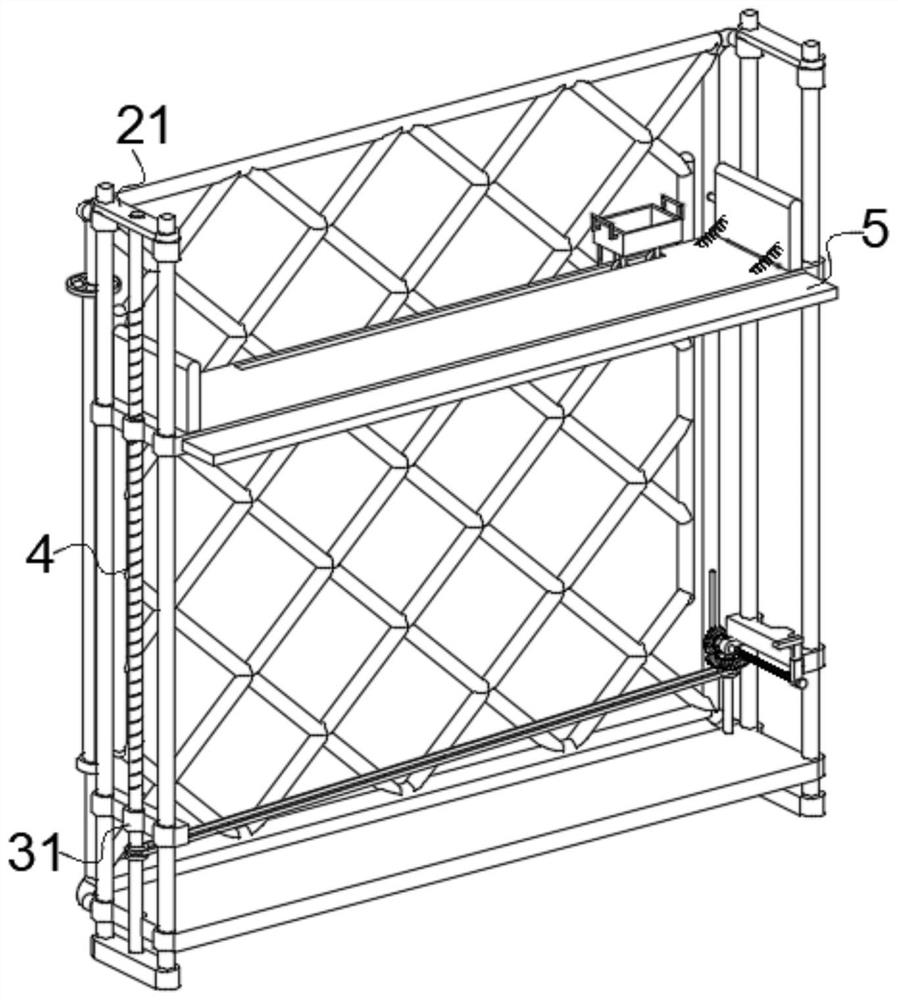

[0056]Considering that the personnel need to stand on the surface of the operating table 5, and the material will also be placed on the surface of the operating table 5, when the material is sand and other materials, a certain vibration force will be generated due to the operation of its own structure, and the inner diameter is smaller. The material placed on the surface of the operating table 5 will be driven by the internal vibration force, so that the material will be shaken out of the operating table 5 and dropped by the vibration. improvements, such as image 3 and 11 shown:

[0057] A storage bin 7 is arranged on the surface of the operation table 5, and the storage bin 7 is used for receiving materials. Two sets of fixed arms 71 are installed at the bottom of the storage bin 7, and pulleys 72 are hinged on the fixed arms 71. The operation platform The surface of the plate 5 is provided with a slideway, and the pulley 72 slides in the slideway. The side of the operatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com