Automatic slide dyeing system

A staining system and technology for glass slides, applied in the field of cell slide staining, can solve the problems of large differences in the staining effect of glass slides, observation, and mutual recognition of glass slides.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

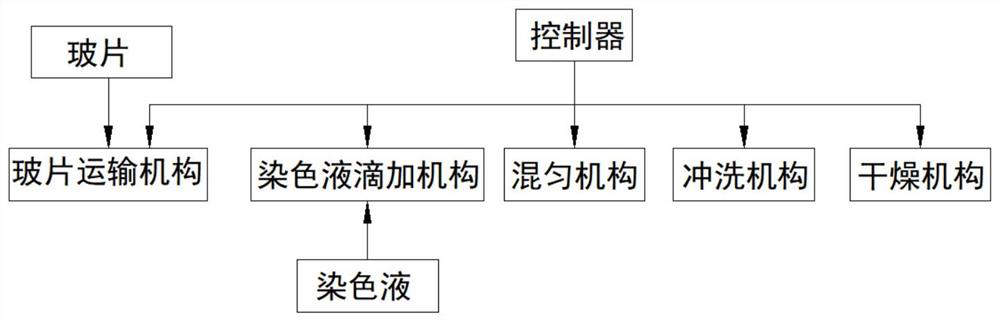

[0019] like figure 1 As shown, an automatic glass slide staining system includes a slide transport mechanism, a staining solution storage bin, a staining drop adding mechanism, a controller, a staining bin, a mixing mechanism, a rinsing mechanism, and a drying mechanism;

[0020] In this embodiment, the slide transport mechanism is provided with an electric slide clamp, a photoelectric sensor, a linear transport guide, a stepping motor and a driver; the dye drop adding mechanism is provided with a check valve, such as a peristaltic pump, pipeline, multi-channel switching Solenoid valve, liquid adding needle; mixing mechanism includes fan and electric swing tuyere; rinsing mechanism includes flushing water, micro pump, nozzle; drying mechanism includes electric heating element, fan and temperature sensor; dyeing liquid storage bin stores different dyeing liquids separately Several kinds, including a variety of dyeing solutions and buffer solutions; the controller includes an em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com