Maintenance electrician skill training and checking device

A skill and electrician technology, applied in the field of repairing electrician skills training and assessment devices, can solve the problems of inability to change the size of the module, changing the size of the module, inconvenient disassembly and assembly, etc., and achieve the effects of reducing capital construction investment, saving housing, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

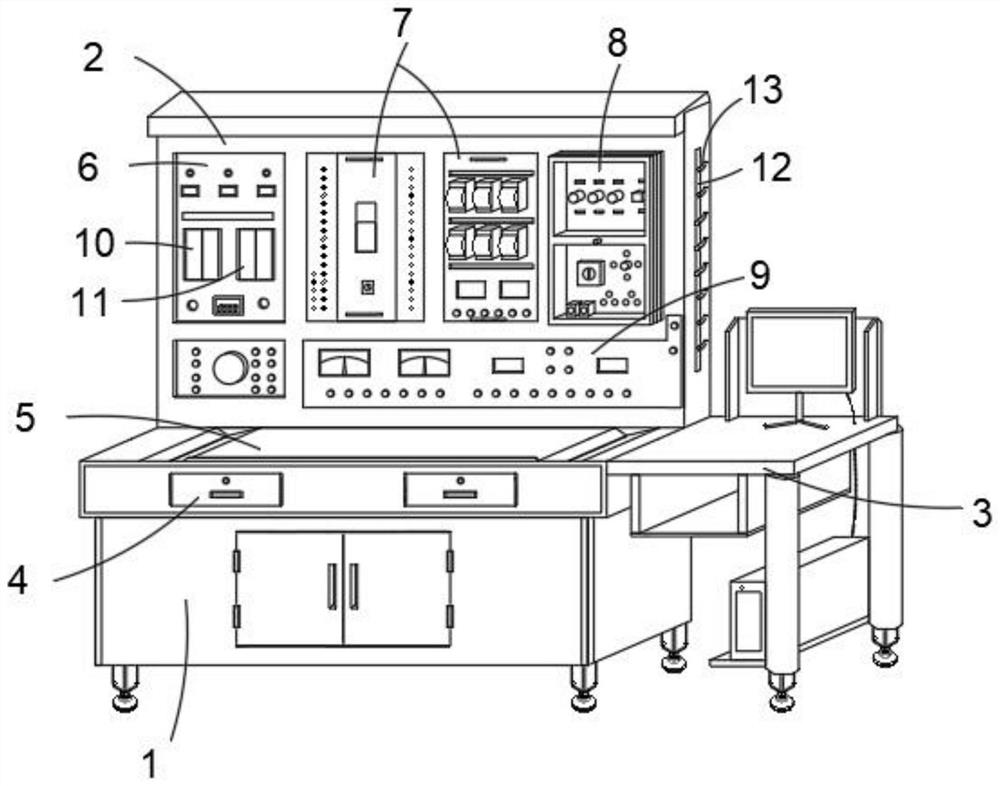

[0044] This embodiment gives the specific structure of the whole device, such as Figure 1-5 As shown in the figure, a maintenance electrician skills training assessment device includes three parts: a bottom box 1, a control panel 2 and a support plate 3,

[0045] The bottom box body 1 is equipped with a collection component for collecting waste; the control panel 2 is arranged on the top of the bottom box body 1, and its front side is arranged in the horizontal direction from left to right as a protection module 6, an installation module 7, and an expansion module. 8 and the display module 9, wherein the specific position of the display module 9 is located below the installation module 7 and the expansion module 8, and each functional area is modular, which is embodied in the above-mentioned various modules, and can be set at the edge of the corresponding functional area. The expansion device, specifically the expansion module 8, reserves a certain space to facilitate expansi...

Embodiment 2

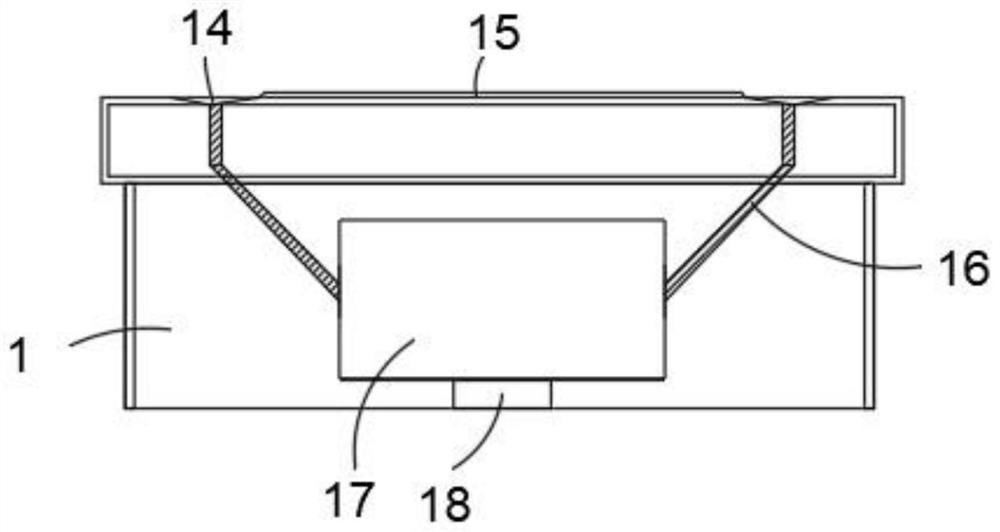

[0050] Based on Embodiment 1, this embodiment provides the specific structure of the collection assembly. The bottom box body 1 is equipped with a collection assembly for collecting waste; the control panel 2 is arranged on the top of the bottom box body 1, and its front side is in the horizontal direction. , from left to right are arranged as protection module 6, installation module 7, expansion module 8 and display module 9 in turn, and a hook assembly is arranged on the side of control panel 2; support plate 3 is arranged on one side of bottom box 1 Wherein, the collection assembly comprises a collection box 17 and a vacuum generator 18 installed at the bottom of the collection box 17, and the collection box 17 communicates with the area on both sides of the table 5 on the bottom box 1; the support plate 3 is provided with a device for controlling the entire assessment host and monitor.

[0051] In some examples, at least two groups of drawers 4 are assembled on the front s...

Embodiment 3

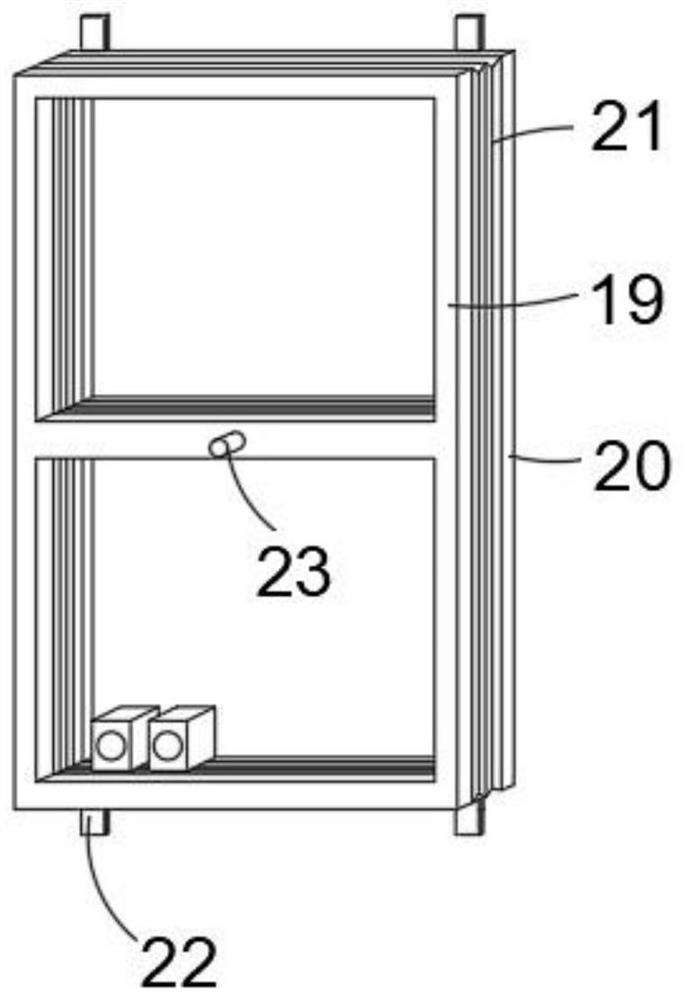

[0054] Based on Embodiment 1, this embodiment provides the specific structure of the protection module. The bottom box body 1 is equipped with a collection assembly for collecting waste materials; the control panel 2 is arranged on the top of the bottom box body 1, and its front side is in the horizontal direction. , from left to right are arranged as protection module 6, installation module 7, expansion module 8 and display module 9 in turn, and a hook assembly is arranged on the side of control panel 2; support plate 3 is arranged on one side of bottom box 1 Wherein, the collection assembly comprises a collection box 17 and a vacuum generator 18 installed at the bottom of the collection box 17, and the collection box 17 communicates with the area on both sides of the table 5 on the bottom box 1; the support plate 3 is provided with a device for controlling the entire assessment host and monitor.

[0055] In some examples, at least two groups of drawers 4 are assembled on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com