Sleeving tool for stator and casing of motor for new energy automobile

A new energy vehicle and stator technology, applied in the field of jigs and fixtures, can solve the problems of time-consuming and labor-intensive assembly work, and the inability to use the gravity of the motor casing, etc., to achieve high-efficiency assembly, save manufacturing costs, and improve assembly efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

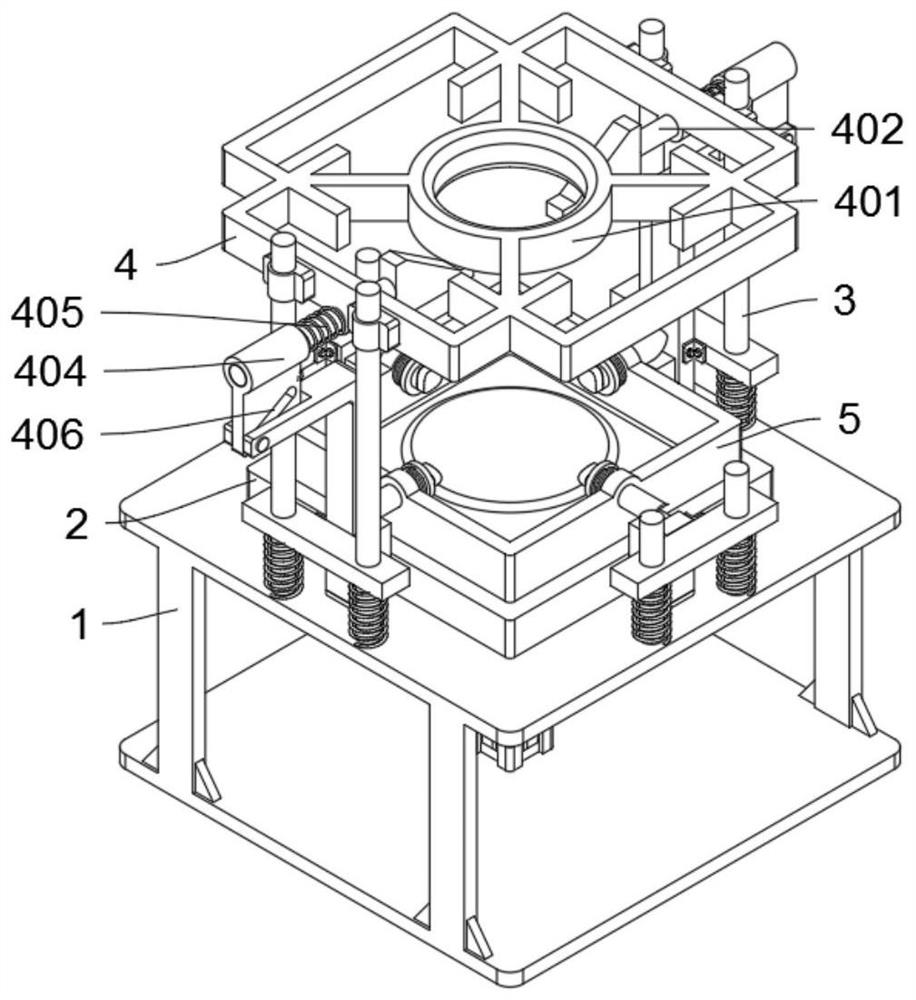

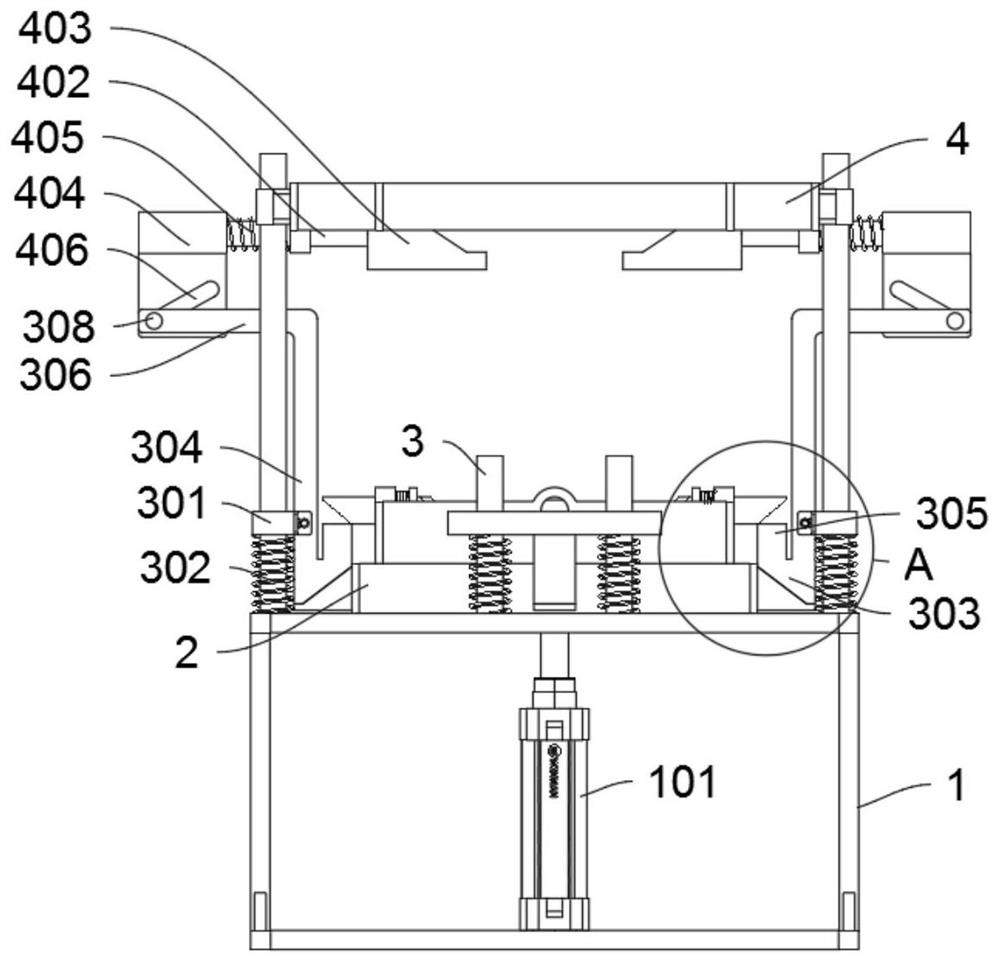

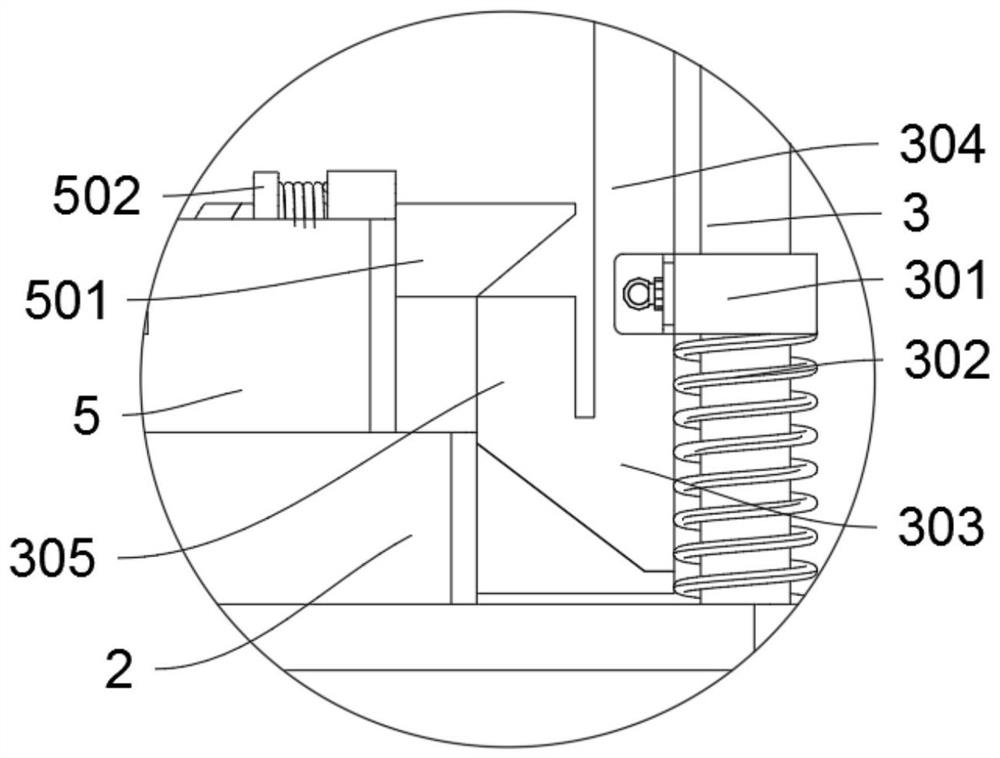

[0049] Example: please refer to Figure 1 to Figure 8 :

[0050] The invention proposes a set tooling for a stator and a casing of a motor for a new energy vehicle, comprising: a main body 1, a positioning member 2 is fixedly installed at the top center position of the main body 1; a hole is opened at the bottom center position of the positioning member 2; A push cylinder 101 is arranged at the inner center position; a carrier rod 3 is arranged on the outer side of the top of the main body 1; a carrier 4 is fixedly installed at the top of the carrier rod 3 on the left and right sides; The side load rod 3; the top of the positioning member 2 is provided with a limiting member 5, which is operated by the pushing cylinder 101 to push the triggering support plate 205 upward through the hole, and restore it, so that the casing is no longer clamped and limited , it is convenient to take out the assembled casing and stator.

[0051] Furthermore, according to embodiments of the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com