Integrated fuel tank structure for amphibious ships

An amphibious and integrated technology, applied in the direction of fuel supply tank device, fluid pressure actuation device, fluid pressure actuation system components, etc., it can solve the problems of affecting the heat dissipation effect, increasing the ambient temperature, and being unable to apply, so as to prevent leakage The hidden danger of oil, the effect of improving safety performance and improving heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

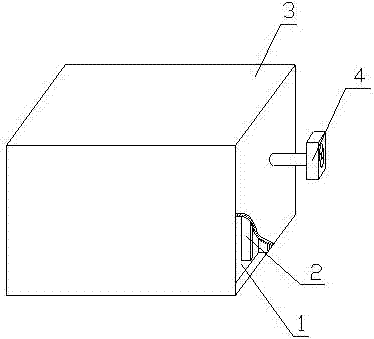

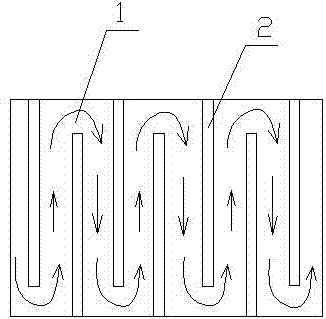

[0018] see Figure 1~2 , the present invention relates to an integrated fuel tank structure for amphibious ships, the structure includes a fuel tank body 1, the fuel tank body 1 is wrapped with a casing 3, the outer tank wall and the cover of the fuel tank body 1 A heat dissipation cavity is formed between the inner shell walls of the shell 3, and a plurality of heat dissipation fins 2 are arranged in parallel in the heat dissipation cavity, and the two sides of the heat dissipation fins 2 are respectively connected to the outer tank wall and the cover On the inner shell wall of the shell 3, the heat dissipation fins 2 are arranged in a staggered manner (staggered up and down or left and right, as shown in Figure 2). The heat dissipation cavity between the two separates the serpentine heat dissipation channel, so that the air flowing through it must go forward along the serpentine heat dissipation channel, which increases the heat dissipation length and heat dissipation time, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com