Auxiliary fire device for gas burner

A gas burner and sub-fire technology, applied in the direction of burner safety devices, gas fuel burners, burners, etc., can solve the problems of high ignition failure rate, short service life, poor safety performance, etc., to avoid misoperation, Long service life, monitoring and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

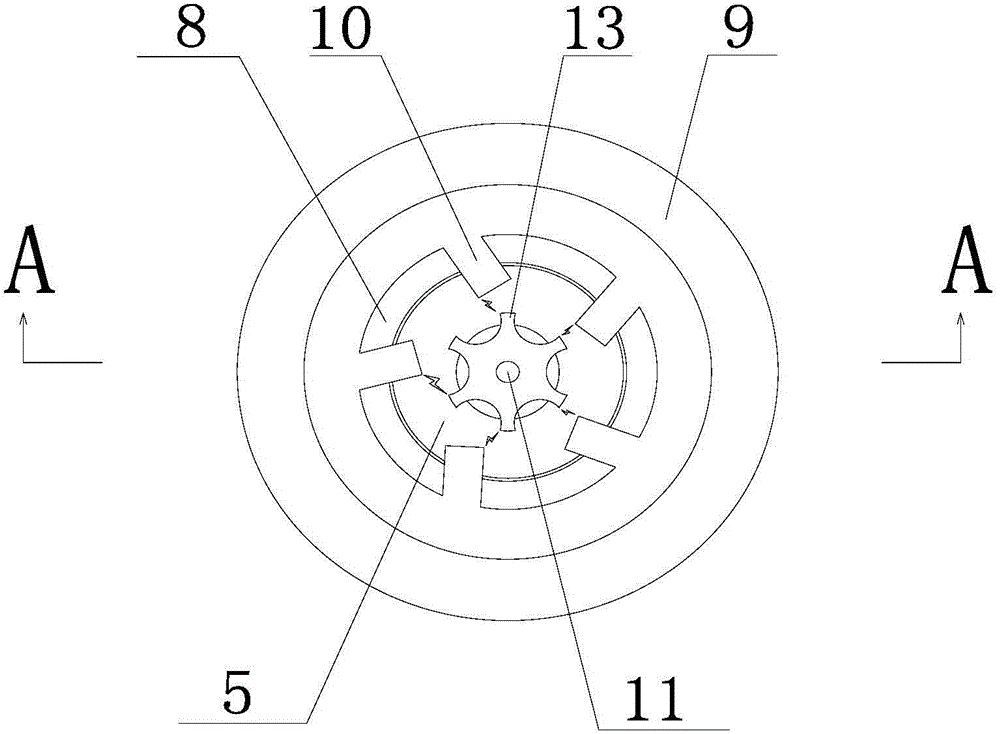

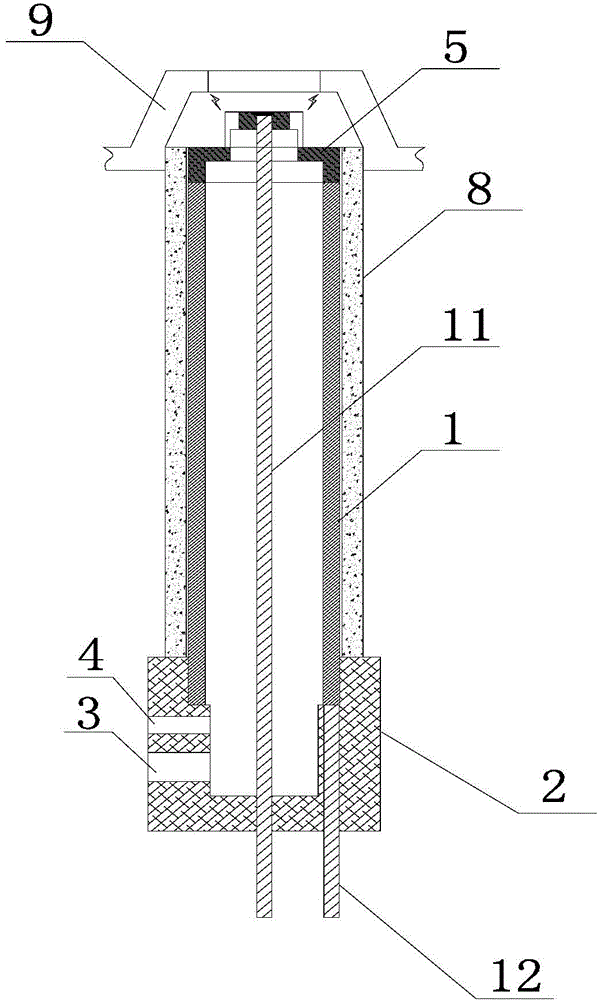

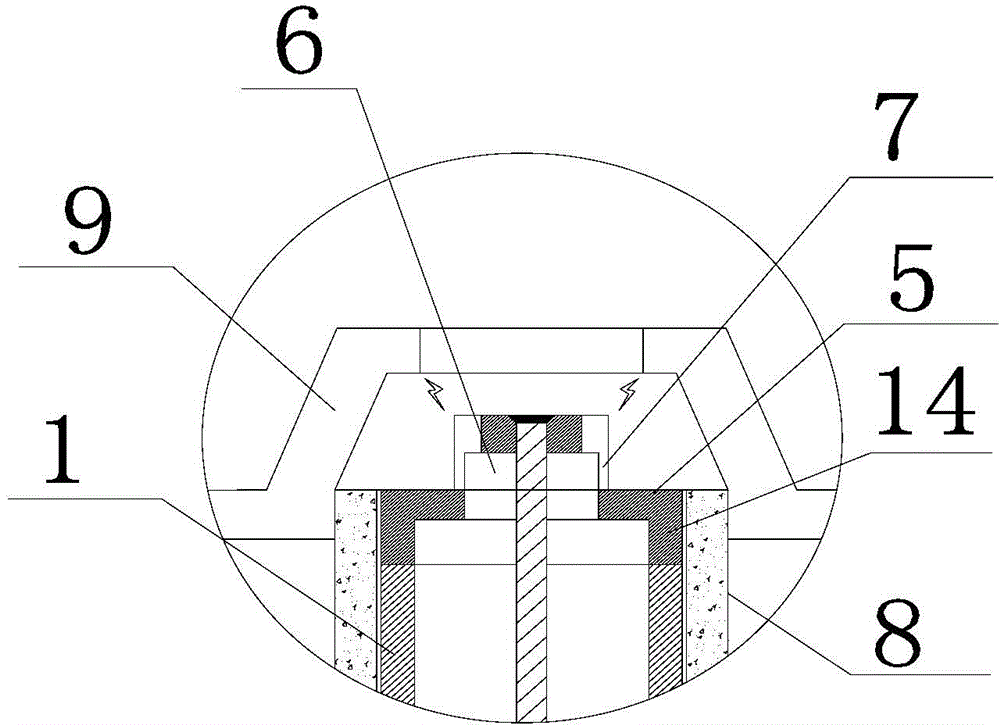

[0046] figure 1 A top view of a sub-ignition device for a gas burner provided in an embodiment of the present invention; figure 2 for figure 1 Middle A-A sectional view; image 3 A partial enlarged view of a secondary fire device for a gas burner provided in an embodiment of the present invention; Figure 1-3 As shown, a sub-ignition device for a gas burner provided in this embodiment includes a metal pipe 1, one end of the metal pipe 1 is connected with an insulating base 2, the insulating base 2 seals the metal pipe 1, and the insulating base 2 is respectively provided with a The air inlet 3 and the gas inlet 4 connected by the metal pipe 1;

[0047] The end of the metal pipe 1 away from the insulating base 2 is provided with a cover 5, and the cover 5 is provided with a protrusion extending upward, and the protrusion is provided with a blind hole 6, the bottom of which is connected to the metal pipe, and the bottom of the blind hole 6 is connected to the metal pipe. Th...

Embodiment 2

[0055] figure 1 A top view of a sub-ignition device for a gas burner provided in an embodiment of the present invention; figure 2 for figure 1 Middle A-A sectional view; image 3 A partial enlarged view of a secondary fire device for a gas burner provided in an embodiment of the present invention; Figure 1-3 As shown, a sub-ignition device for a gas burner provided in this embodiment includes a metal pipe 1, one end of the metal pipe 1 is connected with an insulating base 2, the insulating base 2 seals the metal pipe 1, and the insulating base 2 is respectively provided with a The air inlet 3 and the gas inlet 4 connected by the metal pipe 1;

[0056] The end of the metal pipe 1 away from the insulating base 2 is provided with a cover 5, and the cover 5 is provided with a protrusion extending upward, and the protrusion is provided with a blind hole 6, the bottom of which is connected to the metal pipe, and the bottom of the blind hole 6 is connected to the metal pipe. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com