Multi-product compatible defect detection equipment and detection method thereof

A defect detection, multi-product technology, applied in sorting and other directions, can solve the problems of low detection efficiency, affect the quality of photos, and reduce detection efficiency, and achieve the effect of improving conveying efficiency, improving detection accuracy, and ensuring detection accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

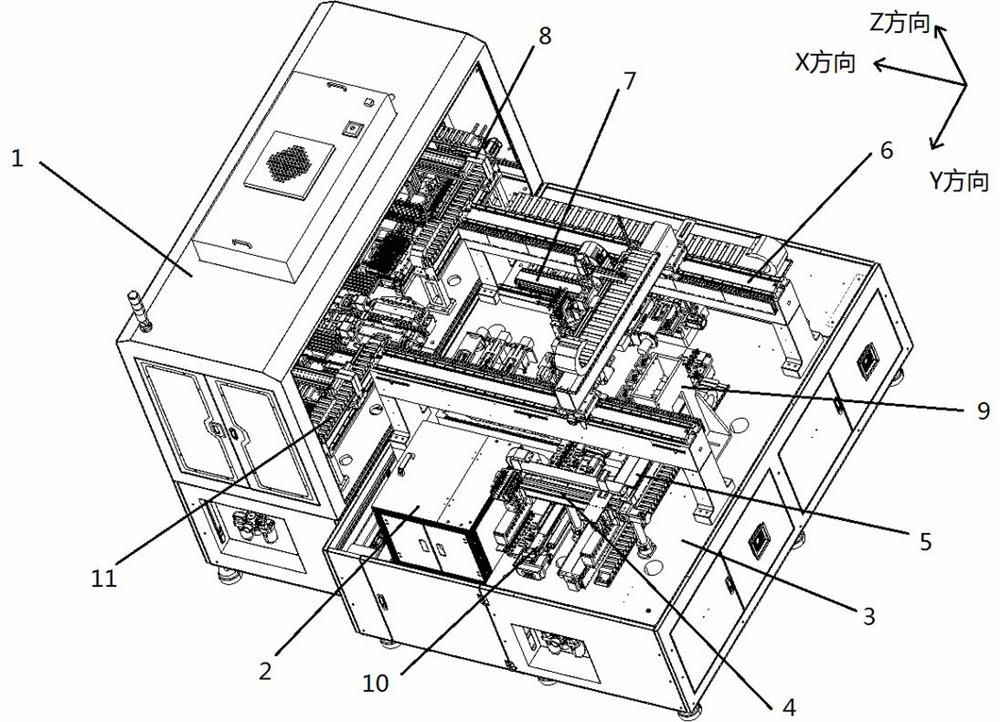

[0055] like Figure 1-2 As shown, the present invention discloses a schematic three-dimensional structure of a multi-product compatible defect detection device.

[0056] A multi-product compatible defect detection device, comprising: a feeding device 2, a detection device and a feeding device 1 are arranged in sequence,

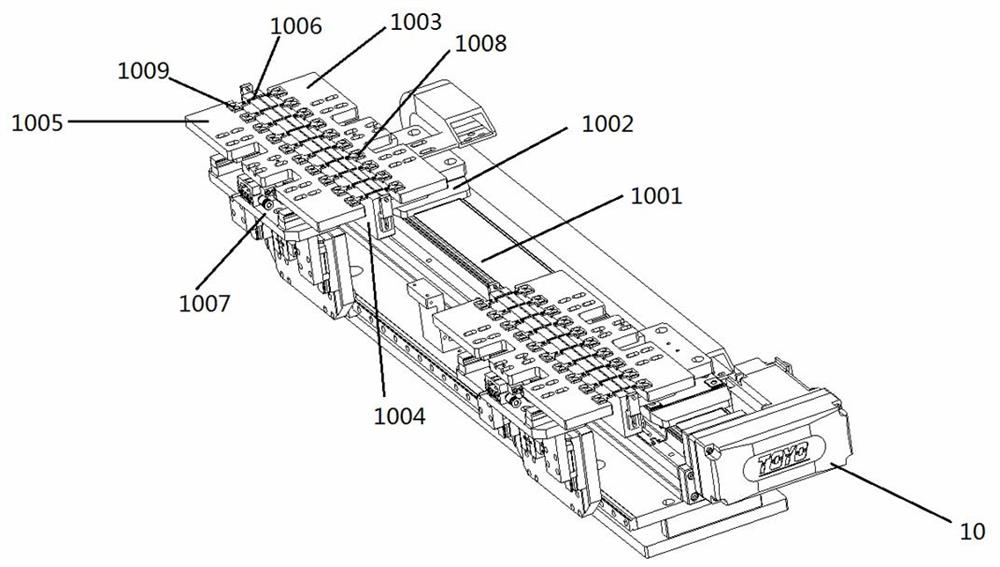

[0057] A vibrating plate 206 is arranged inside the feeding device 2, a feeding conveying mechanism 202 is disposed on one side of the vibrating plate 206, and at least one feeding channel 207 is arranged inside the feeding and conveying mechanism 202, and the feeding channel 207 is used for conveying the mobile phone buttons 208;

[0058] Further, the material is loaded by the vibrating plate 206, and two feeding channels 207 are arranged side by side on one side of the vibrating plate 206, so that the mobile phone keys 208 can be adjusted in the same direction and then conveyed, so as to improve the conveying efficiency of the mobile phone keys 208, and at ...

Embodiment 2

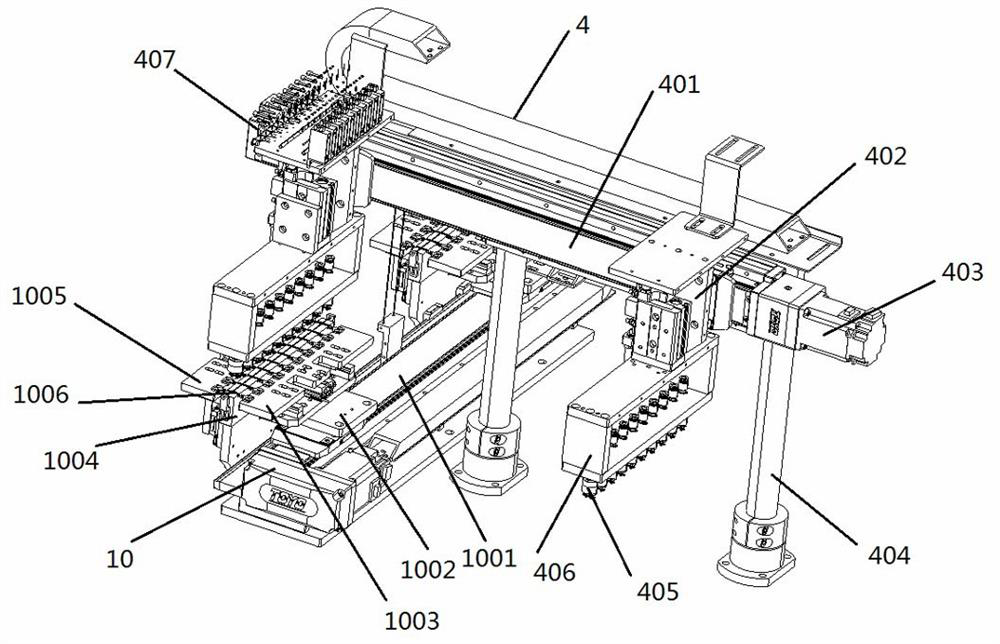

[0091] A defect detection method, applied to multi-product compatible defect detection equipment, includes the following steps: S1, the feeding device 2 adjusts the mobile phone buttons 208 to the same direction through the vibrating plate 206, and conveys to the receiving device through the feeding and conveying mechanism 202. In the groove 1006, after the mobile phone button 208 enters the receiving groove 1006, the second card board 1005 is lifted up by the lifting mechanism 1007 to fix the mobile phone button 208;

[0092] S2, the mobile phone buttons 208 in the plurality of receiving grooves 1006 are simultaneously grabbed and moved to the conveying jig 502 on the first conveying module 5 by several grabbing suction heads 405 on the grabbing module 4, and the conveying jig is 502 is detected by the second detection module 9 during the movement of the first conveying module 5;

[0093] S3, after the second module detection is completed, the mobile phone button 208 on the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com