Ship drag reduction system and drag reduction method thereof

A ship and bow technology, applied in the ship drag reduction system and its drag reduction field, can solve the problems that the reverse jet drag reduction technology has not attracted widespread attention, and the drag reduction effect has been discounted, so as to eliminate the singleness, improve the high pressure area, The effect of improving drag reduction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further clarified below in conjunction with the accompanying drawings and specific embodiments. It should be understood that these embodiments are only used to illustrate the present invention and not to limit the scope of the present invention.

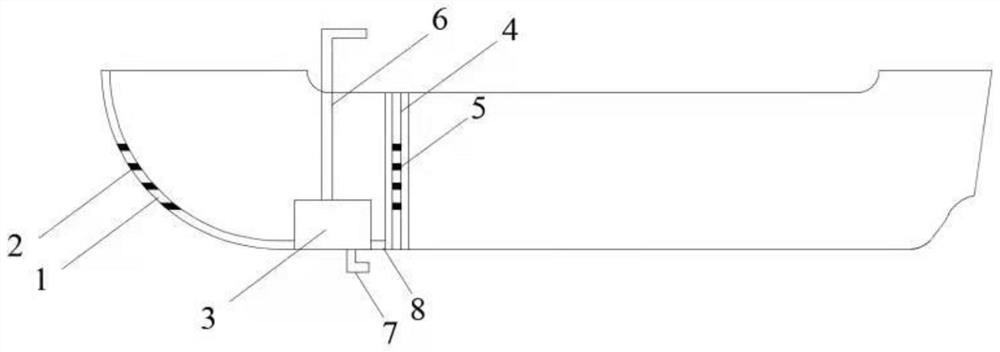

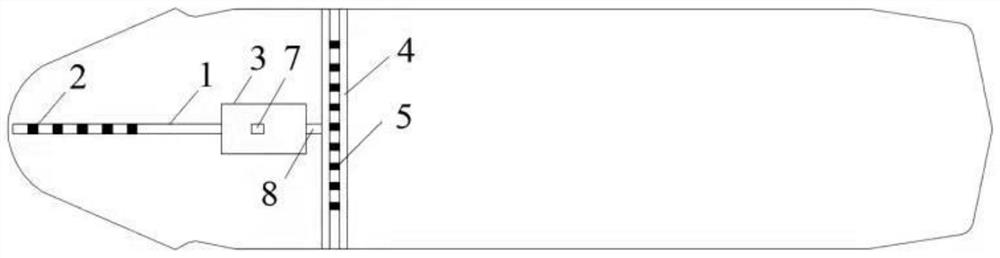

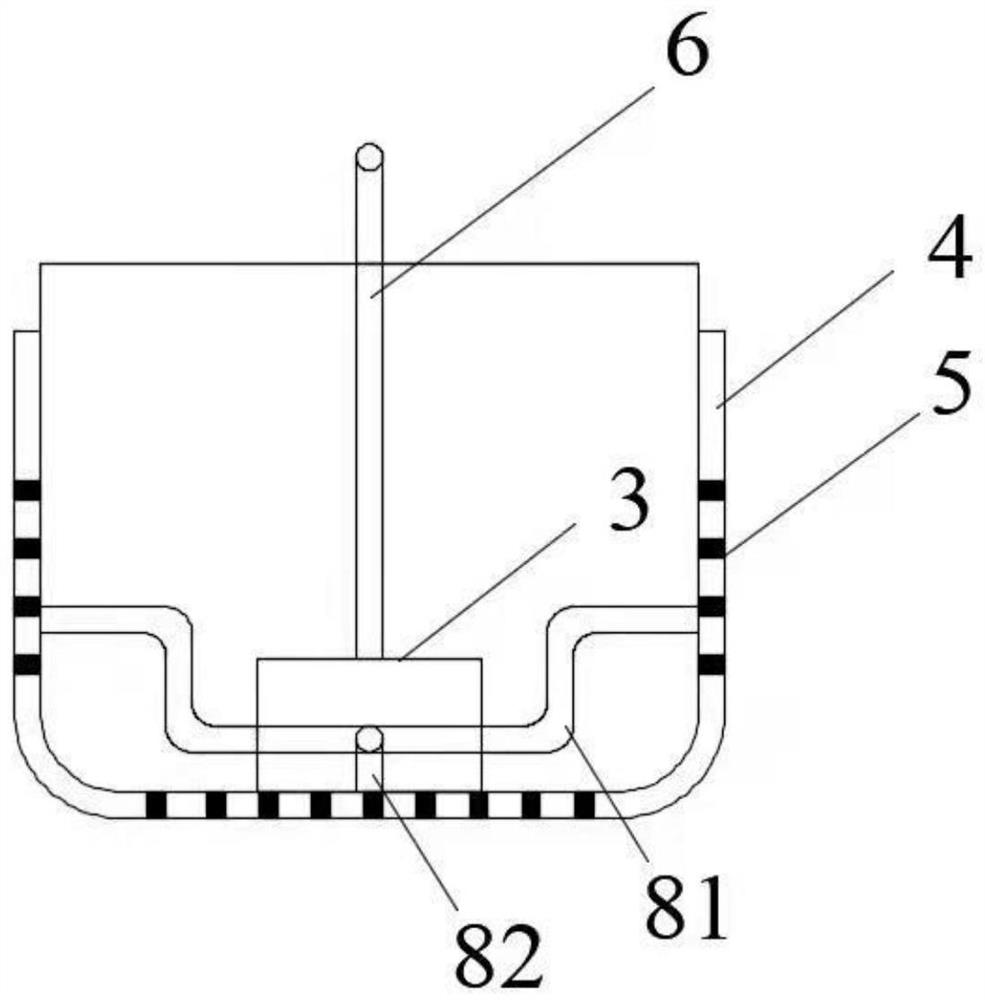

[0024] A ship drag reduction system, such as Figures 1 to 4 As shown, it includes an upstream liquid spray device, a jet device, a high-pressure pump 3, a control device, an air inlet pipe 6, and a water inlet pipe 7.

[0025] The high-pressure pump 3 is installed at the bottom of the bow, and its opposite sides are respectively provided with an upstream spray device and a jet device. The upstream spray device is installed at the bow of the ship. The air inlet of the high-pressure pump 3 is sealed with one end of the air intake pipe 6. The other end of the air inlet pipe 6 extends above the ship, the water inlet of the high pressure pump 3 is sealedly connected to one end of the water inlet pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com