Bearing platform for platform type home elevator

A home elevator and load-carrying platform technology, which is applied to elevators, hoists, transportation and packaging in buildings, etc., can solve problems such as troublesome installation and disassembly, large load capacity, and poor safety performance, and achieve convenient installation and disassembly, and high safety performance Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

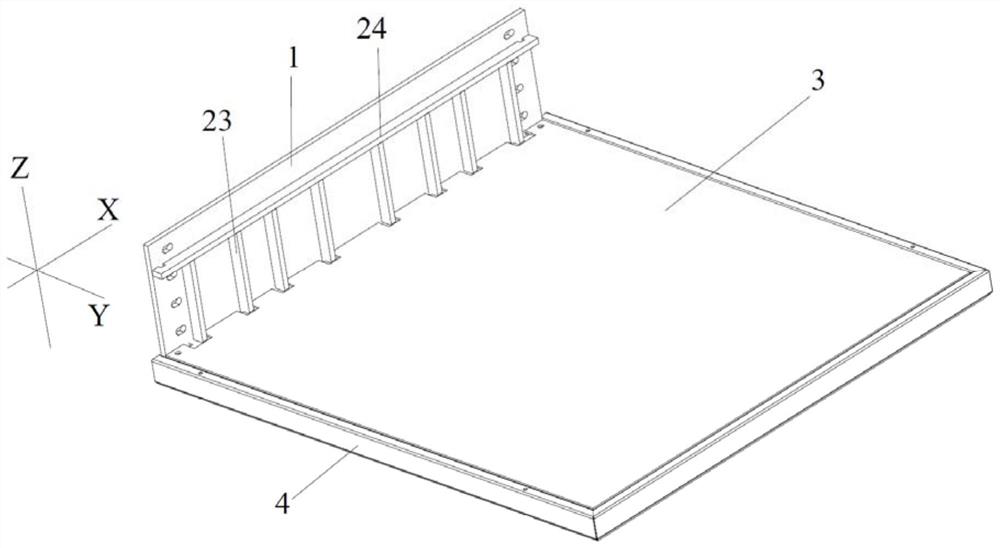

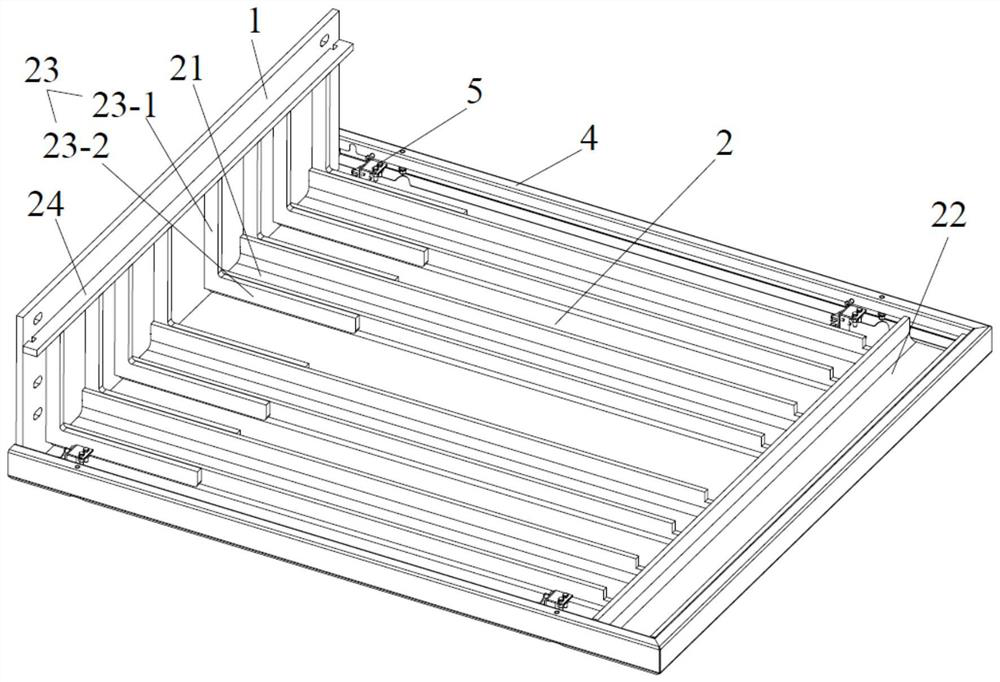

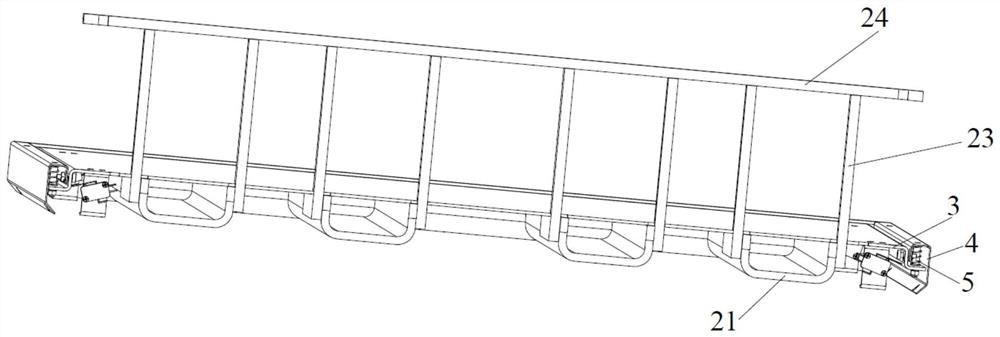

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings: Figures 1 to 4 As shown, the present invention includes a base plate 1, a carrying component 2 and a platform board 3 for carrying people or objects. The platform board 3 is installed and fixed above the carrying component 2, and the carrying component 2 is fixedly connected to one side of the base plate 1. The base plate 1 The other side is connected with two symmetrically distributed mounting plates 6, the two mounting plates 6 are distributed along the X-direction of the bearing platform, and the mounting plates 6 are integrally bent into an L shape, one side of which is fixed with the base plate 1, and the other side is The guide shoe 7 is fastened, so that the entire bearing platform can be installed on the elevator guide rail through the mounting plate 6 fastened with the guide shoe 7 and ensure that the force of the bearing platform is directly transmitted to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com