Special lifting appliance for triangular iron core

A triangle iron and spreader technology, applied in the direction of load hanging components, transportation and packaging, etc., can solve the problems of iron core loss, iron core cannot be translated, low hoisting efficiency, etc., to avoid the movement of the spreader, improve efficiency, and hoisting quality Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

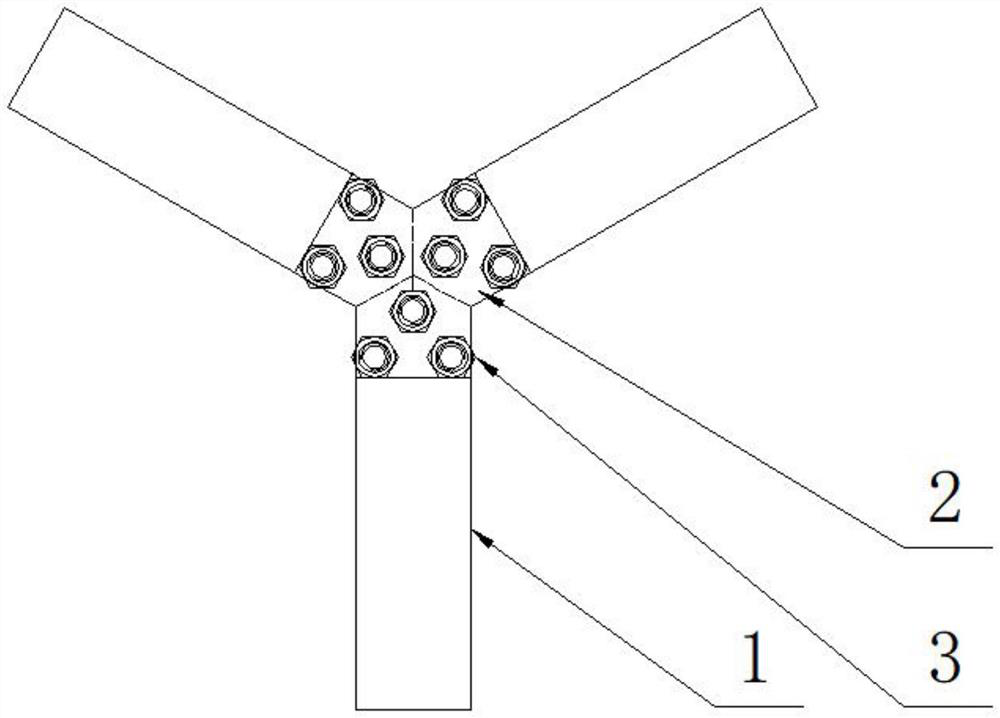

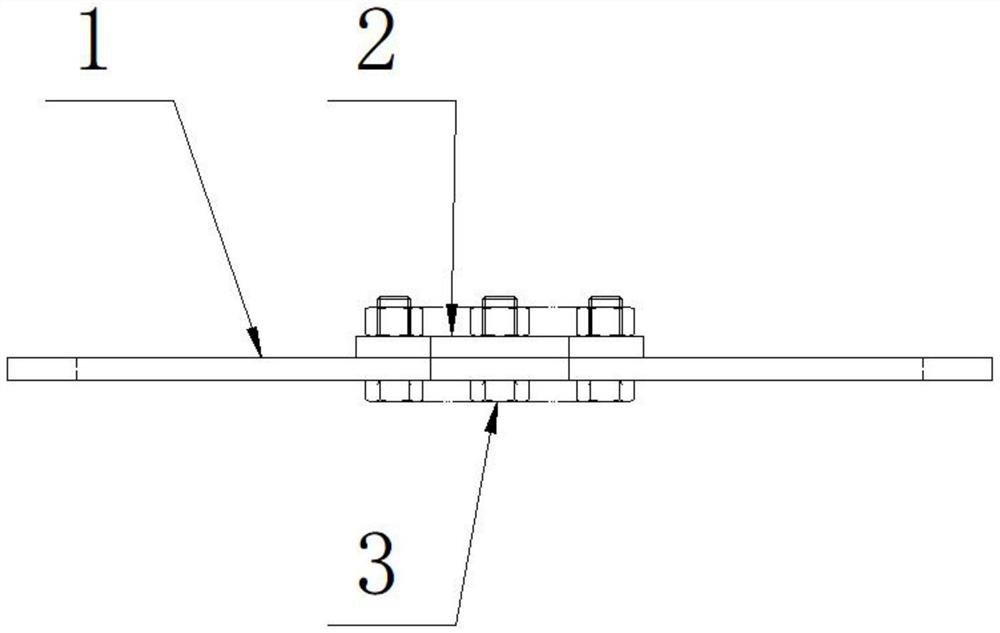

[0032] like figure 1 and figure 2 As shown, a special hanger for a triangular iron core includes a main hanger plate 1 and a reinforcing plate 2. The main hanger plate 1 is a plate in the form of three blades arranged horizontally, and the three blades are evenly arranged around the circumference. The three blades can respectively protrude under the three window top beams of the triangular iron core to be hoisted. The reinforcing plate 2 is superimposed on the middle part of the main hanger plate 1 .

[0033] When hoisting, the special hanger for the triangular iron core of the present invention is tilted and placed into the triangular iron core from the top opening of the triangular iron core to be hoisted, and the three blades respectively probe into the three windows of the triangular iron core that needs to be hoisted. Below the top beam, use a sling to kidnap to the middle part of the superimposed reinforcement plate 2, and lift it from the midpoint.

[0034] Specific...

Embodiment 2

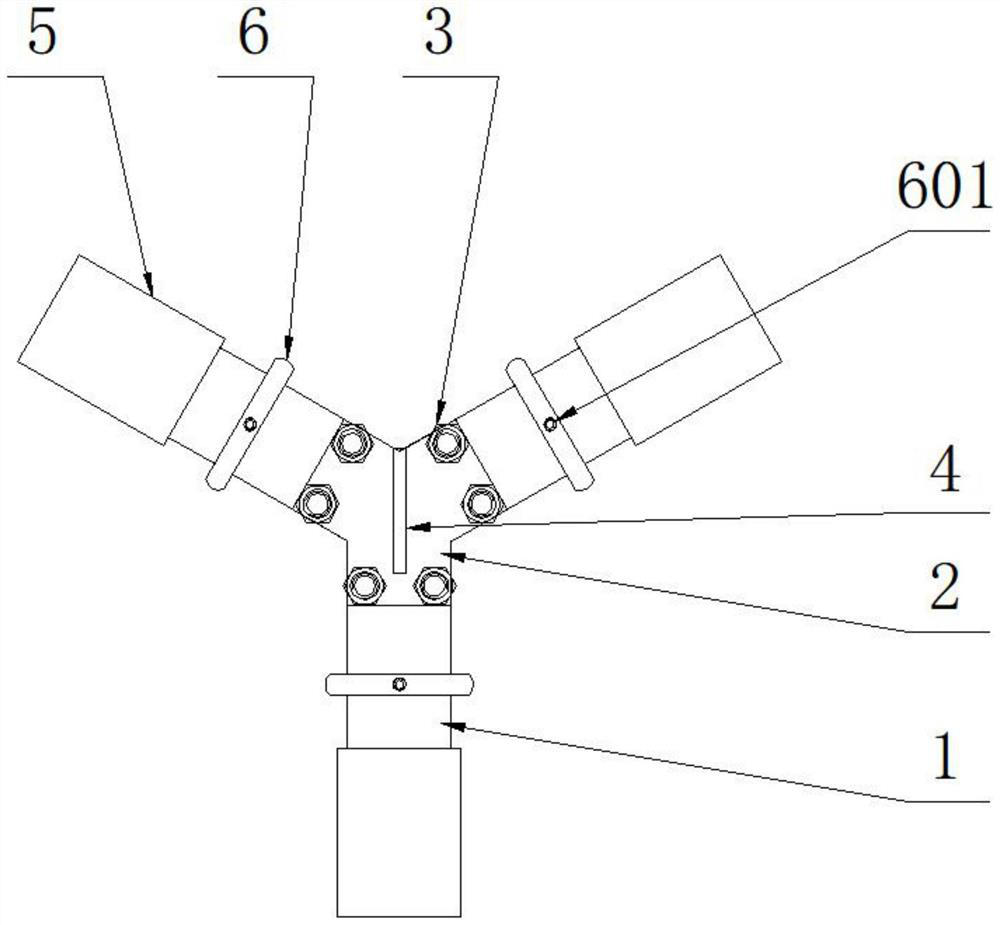

[0037] On the basis of the above embodiment 1, the lifting point is added to form this embodiment, such as image 3 and Figure 4 As shown, the reinforcing plate 2 is arranged above the main hanging plate 1, and the middle of the reinforcing plate 2 is vertically welded with a lifting lug plate 4, and the hanging lug plate 4 is provided with a lifting hole. The hoisting hole connects the sling and the hook through a U-shaped shackle.

[0038] By welding the lifting lug plate 4 in the middle of the reinforcing plate 2, the position is reasonable, the lifting can be balanced, and the lifting is convenient after connecting the lifting strap, which further improves the operation efficiency.

[0039] Specifically, as image 3 and Figure 4 As shown, the outer end of the blade is sleeved with an outer pad 5, and the top surface pad of the outer pad 5 is arranged below the top beam of the window.

[0040] Specifically, as image 3 and Figure 4 As shown, the jacket pad 5 is mad...

Embodiment 3

[0046] On the basis of the above-mentioned embodiment 1, the lifting point is added to form this embodiment, such as Figure 5 As shown, the special hanger for the triangular iron core of the present invention also includes a lifting ring 7 and a screw connecting piece 8. The screw connecting piece 8 passes through the middle hole of the main hanger plate 1 and the reinforcing plate 2 and is locked by the lock nut, and the top of the screw connecting piece 8 is locked. The threaded connection lifting ring 7 is also locked by a nut.

[0047] Through the arrangement of the hoisting ring 7 and the screw connecting piece 8, the main hoisting plate 1 and the reinforcing plate 2 can be locked while forming a hoisting point, which is convenient for smooth hoisting and quick installation of the suspender.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com