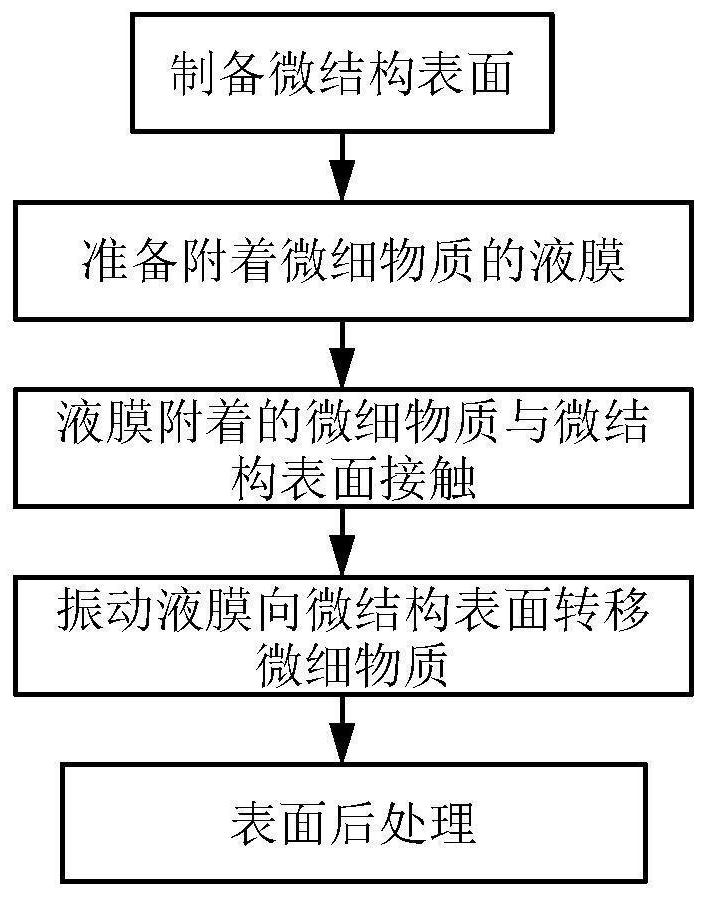

Liquid film transfer printing method of surface microstructure

A microstructure and liquid film technology, applied in microstructure technology, microstructure devices, manufacturing microstructure devices, etc., can solve problems such as poor controllability and poor orientation, less requirements for preparation conditions, high transfer efficiency, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

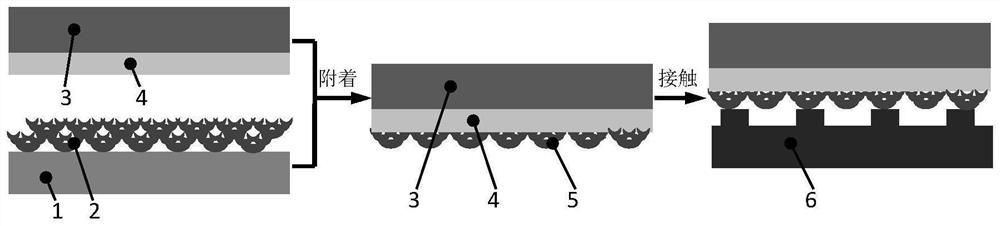

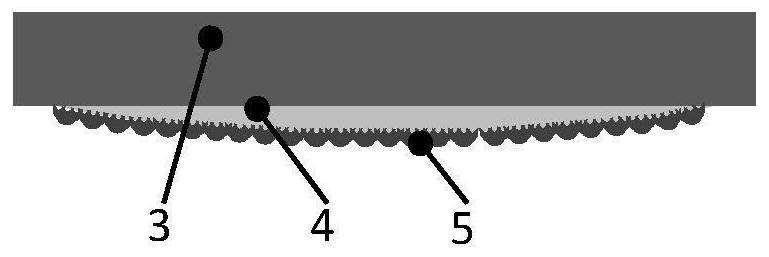

[0037] Example: LiOH solution is used to prepare a liquid film with fine substances attached, and the microstructure surface 6 is a silicon wafer processed by laser

[0038] see attached Figure 5, using the laser direct writing method to prepare a well-shaped groove structure on the surface of the silicon wafer to form a laser-processed microstructure surface 11, the width of the recessed part 12 of the laser-processed microstructure surface is about 50 μm, and the surface is silanized to improve the surface. Adhesion of fine substances. The prepared laser-machined microstructure surface 11 is placed horizontally, and a small amount of broken silicon wafers are laid on the laser-machined microstructure surface 11 as a spacer block. Pour a small amount of LiOH solution onto a smooth silicon wafer, spread the LiOH solution into a thin liquid film by blowing air, and blow carbon dioxide gas to the liquid film to make the surface of the liquid film react to generate fine substan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com