Interlocking condition detection method and semiconductor process equipment

A technology for process equipment and condition detection, applied in the directions of comprehensive factory control, comprehensive factory control, program control, etc., can solve the problem that the semiconductor process equipment cannot quickly determine the fault point, so as to improve the efficiency of troubleshooting, quickly determine, and narrow the troubleshooting. range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the above objects, features and advantages of the embodiments of the present invention more clearly understood, the embodiments of the present invention will be described in further detail below with reference to the accompanying drawings and specific implementation manners.

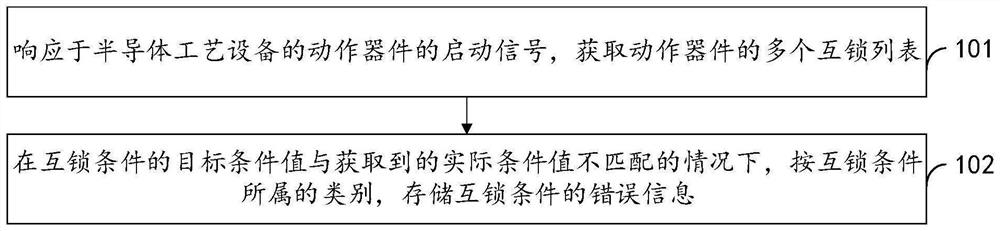

[0032] refer to figure 1 , showing a flow chart of the steps of an embodiment of an interlock condition detection method provided in this embodiment. The method is applied to semiconductor process equipment and may include:

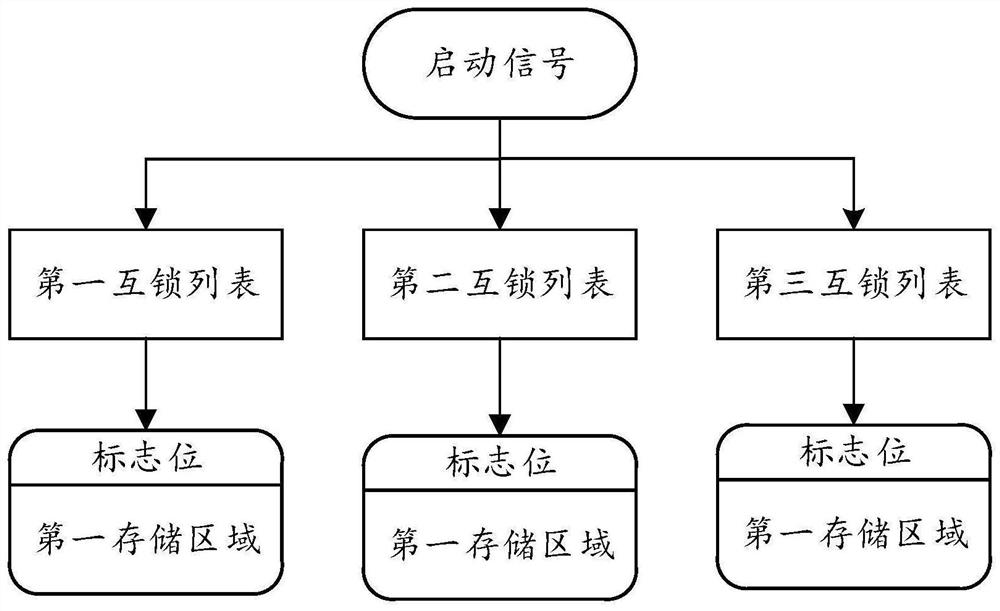

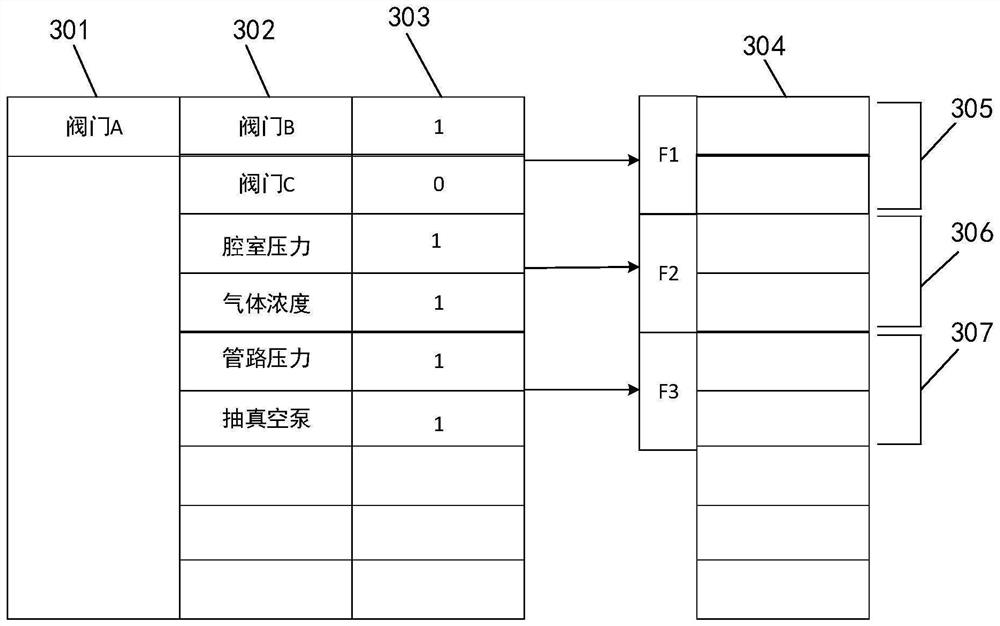

[0033] Step 101: Acquire a plurality of interlock lists of the active devices in response to the activation signal of the active device of the semiconductor process equipment.

[0034] Wherein, each interlock list includes a category of interlock conditions and target condition values of the interlock conditions.

[0035] In this embodiment, the interlock condition detection method may be implemented by a lower computer in the semiconductor process equipme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com