Cutting tool

A technology for cutting tools and shells, which is applied in the direction of manufacturing tools, metal sawing equipment, metal processing equipment, etc., and can solve the problems of large volume, unfavorable motor performance and long-lasting operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

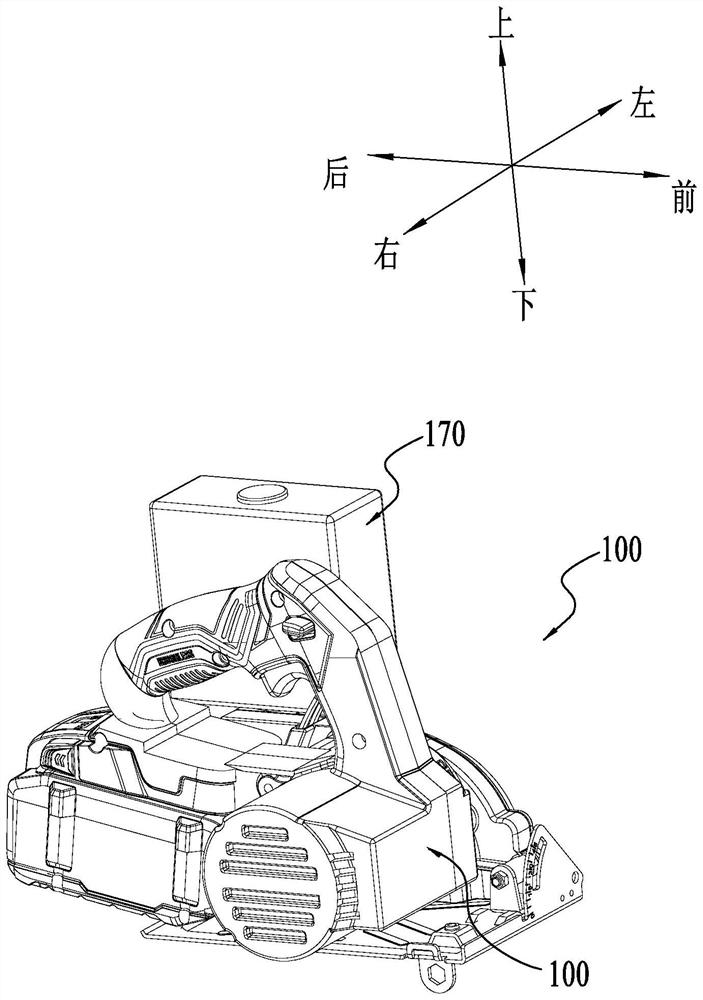

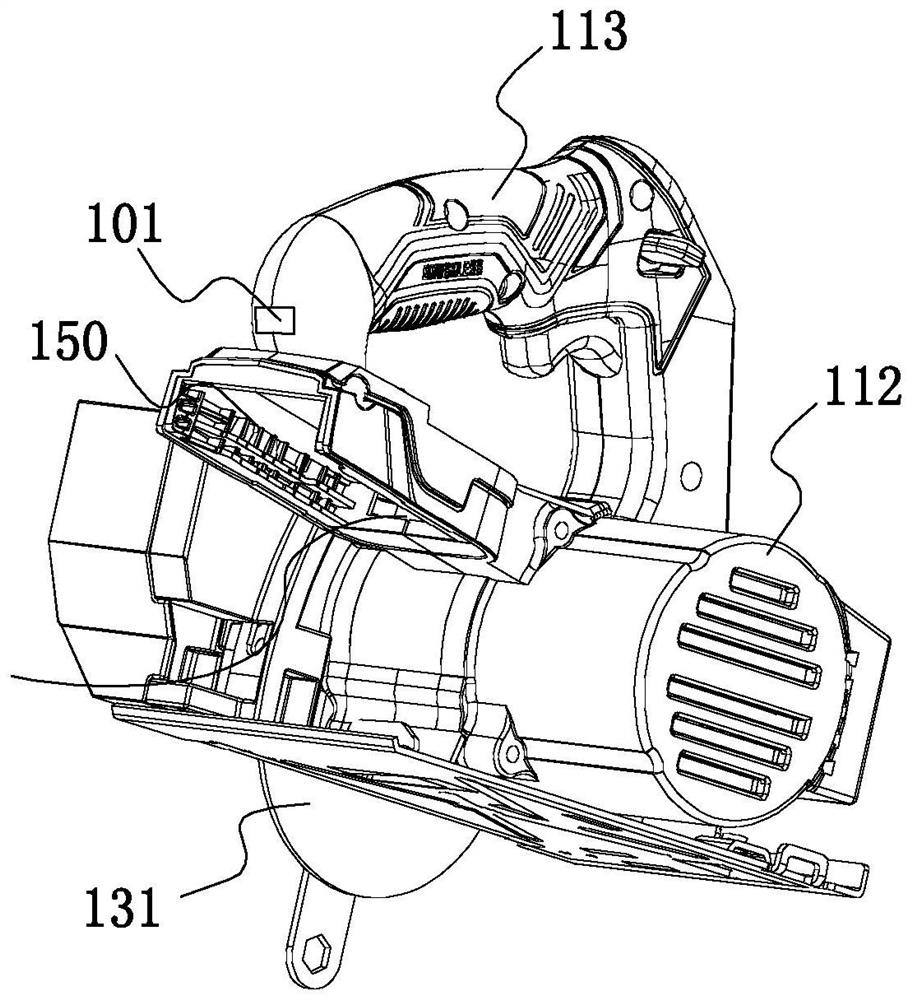

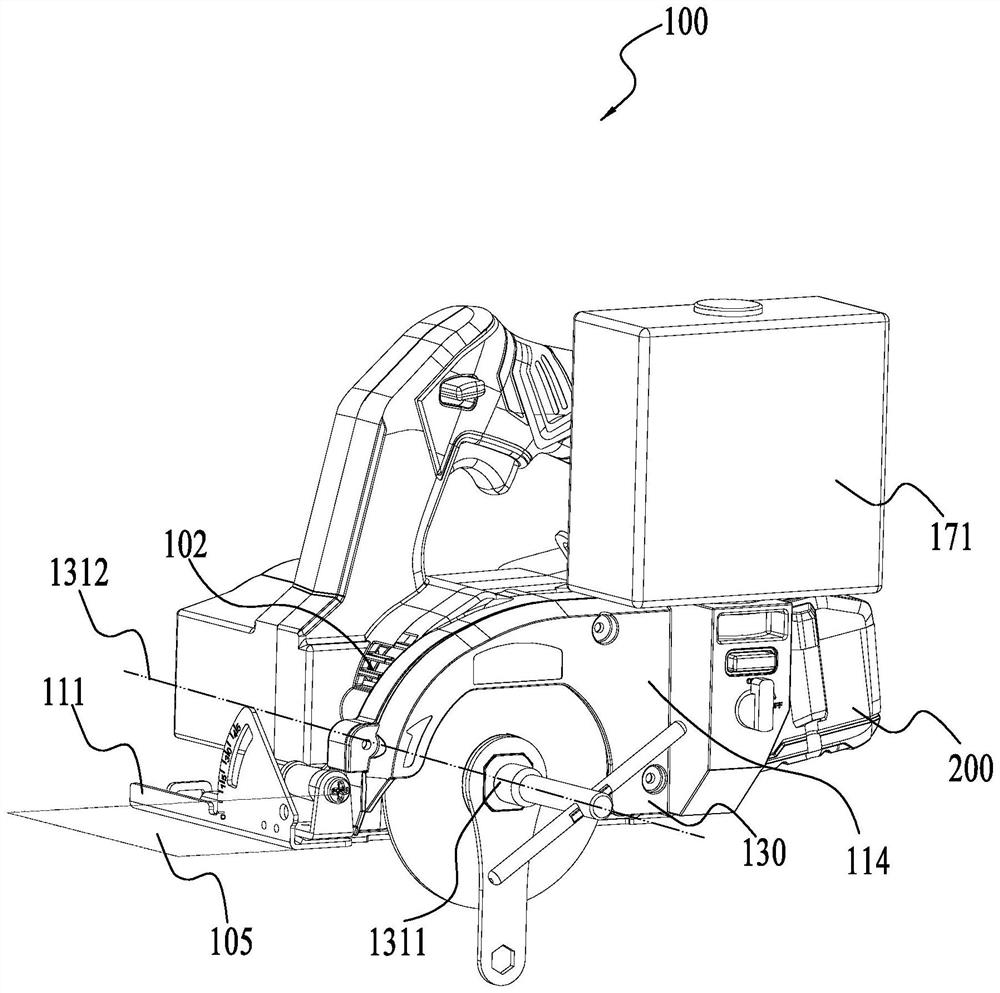

[0036] In one embodiment of the present invention, refer to Figure 1 to Figure 3 , to provide a cutting tool 100, specifically a marble machine, which can be used to cut workpieces such as stone, and grinds and cuts the stone by driving the grinding disc 131 to rotate. The cutting tool 100 includes a housing 110 , a motor 120 , an accessory mounting portion 130 and a transmission mechanism 140 , the motor 120 is supported by the housing 110 , the accessory mounting portion 130 includes an output member 1311 connected to the grinding disc 131 , and the transmission mechanism 140 connects the output member and the motor 120. The cutting tool 100 also includes a power interface 150 for accessing a power source. In one embodiment, the power source may be AC mains. In one embodiment, the power source is a DC power source, such as a battery pac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com