Oxygen-enriching machine

A technology of an oxygenation device and aerator, which is used in water/sludge/sewage treatment, animal husbandry, mixing methods, etc., can solve the problems of affecting the oxygenation effect, uneven oxygenation of water bodies, and reduced water flow, etc. The structure of the whole machine is improved, which is conducive to maintenance and reduces the air resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

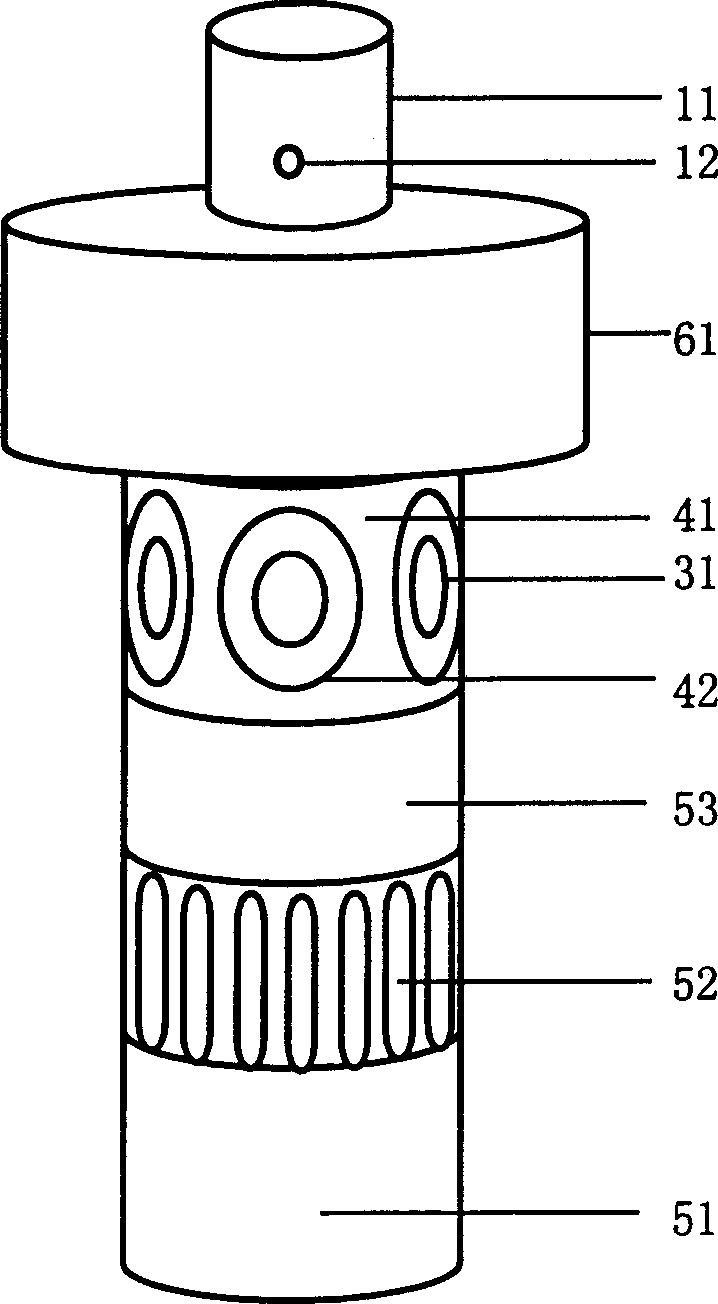

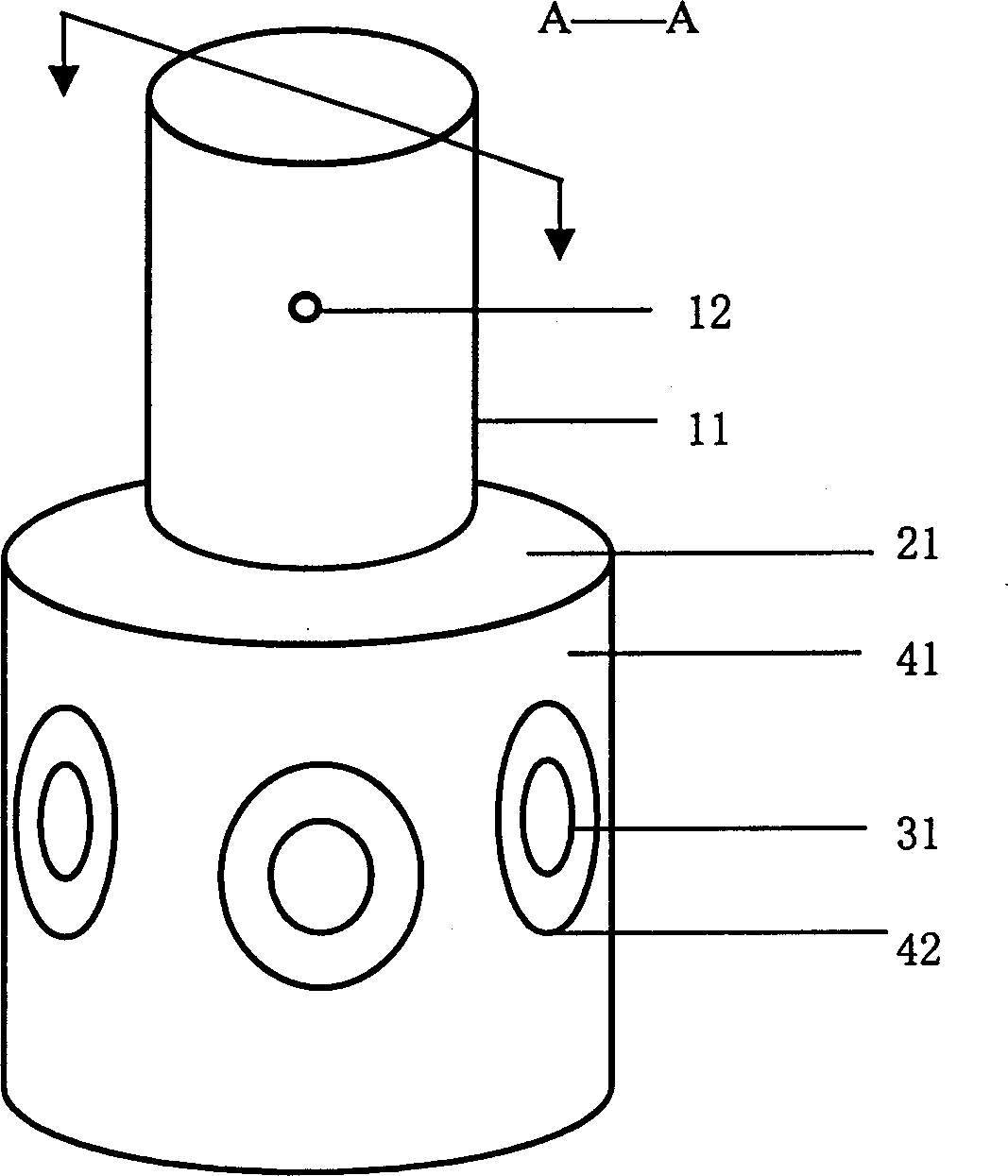

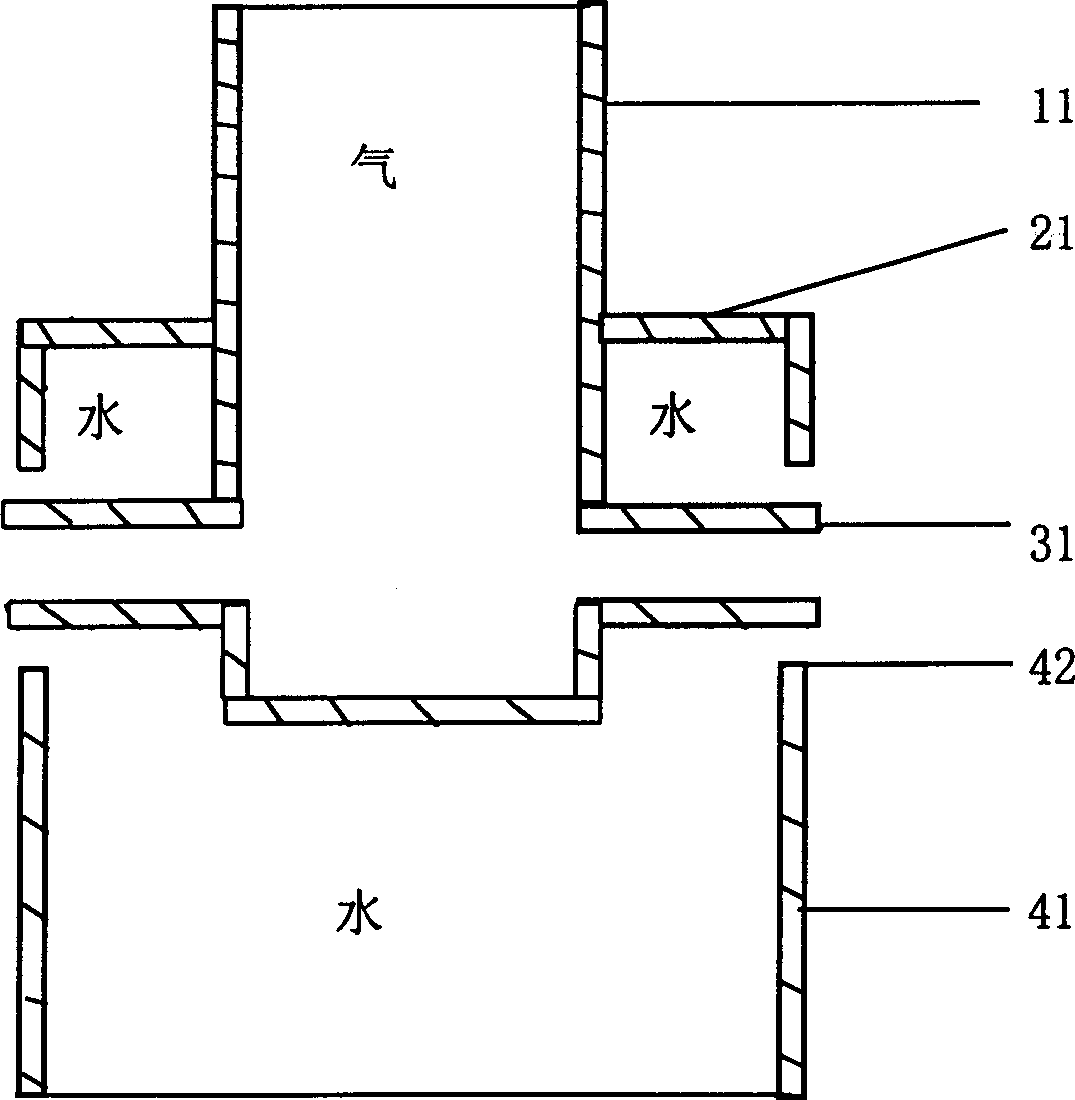

[0015] Preferred embodiments of the present invention such as figure 1 , wherein the gas main pipe 11, the jellyfish pipe 41, and the air branch pipe 31 all adopt a cylindrical structure, and the nozzle hole 42 is a circular hole. The outlet of the gas branch pipe 31 and the nozzle hole 42 form a double-channel nozzle. The air main pipe 11 communicates with the air branch pipe 31 to form an air passage. The space surrounded by the outer wall of the gas branch pipe 31 and the nozzle hole 42 constitutes a water channel. The geometric dimensions of the six double-channel nozzles are equal, and the angles between them are each 60 degrees. When working, the upper mouth of the gas main pipe is exposed to the water surface, the whole machine is vertical to the water surface and floats in the water body, and the 6 double-channel nozzles are below the water surface. The water in the lower layer enters the filter screen 52, and under the action of the pump body 53, this part of the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com