Cylindrical surface printing control method and device, control panel, printer and medium

A printing control, cylindrical technology, applied in printing devices, copying/marking methods, typewriters, etc., can solve the problems of printing effect decline, picture stretching, etc., and achieve the effect of ensuring image accuracy and avoiding stretching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

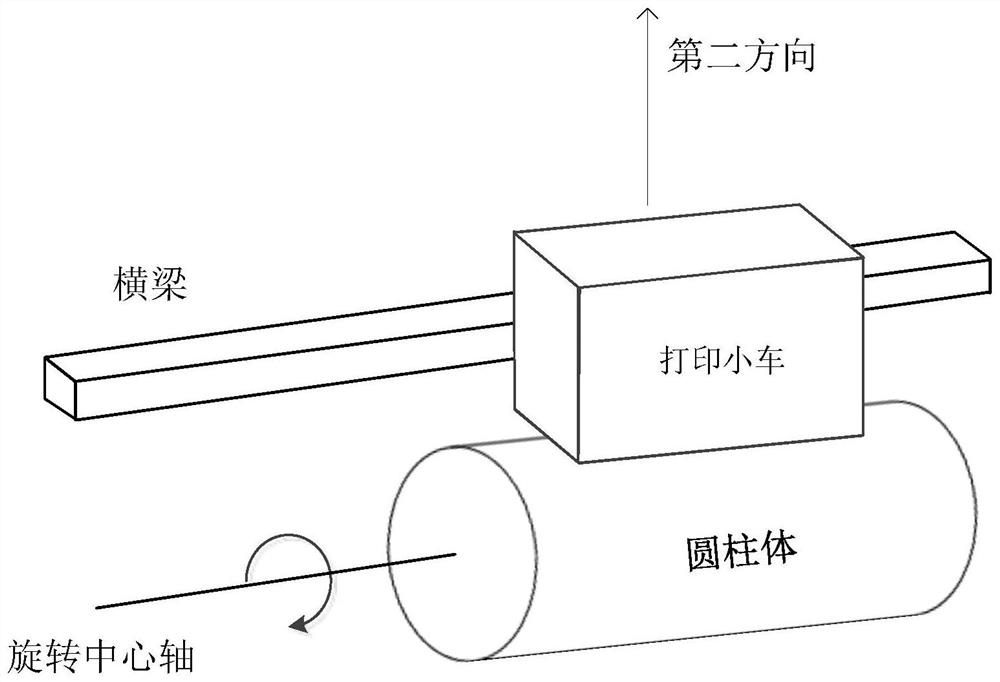

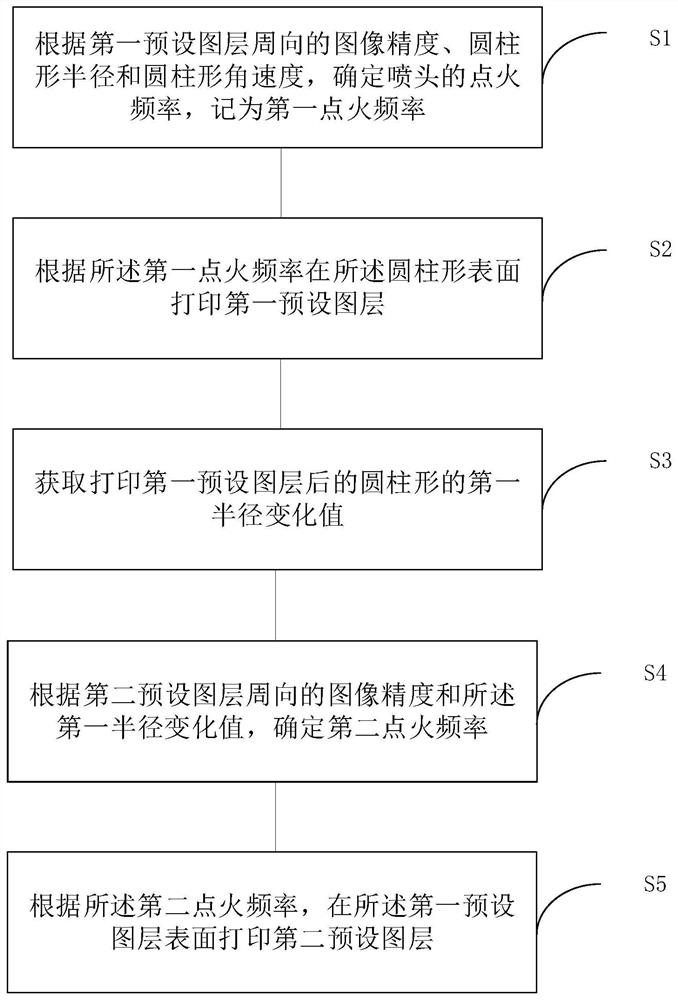

[0055] See figure 2 , a cylindrical surface printing control method provided by the embodiment includes the following steps:

[0056] S1: According to the circumferential precision of the first preset layer, the cylindrical radius and the cylindrical angular velocity, determine the ignition frequency of the nozzle, which is recorded as the first ignition frequency;

[0057] Let the cylindrical radius be R, the image accuracy in the circumferential direction of the layer to be printed is D, the angular velocity is ω, the linear velocity is v, and the ignition frequency is F.

[0058] The calculation relationship between image accuracy D, linear velocity v and ignition frequency F is as follows:

[0059] D=F / v;

[0060] Among them, the linear velocity v=ω×R;

[0061] It can be known that D=F / (ω×R), or F=ω×R×D.

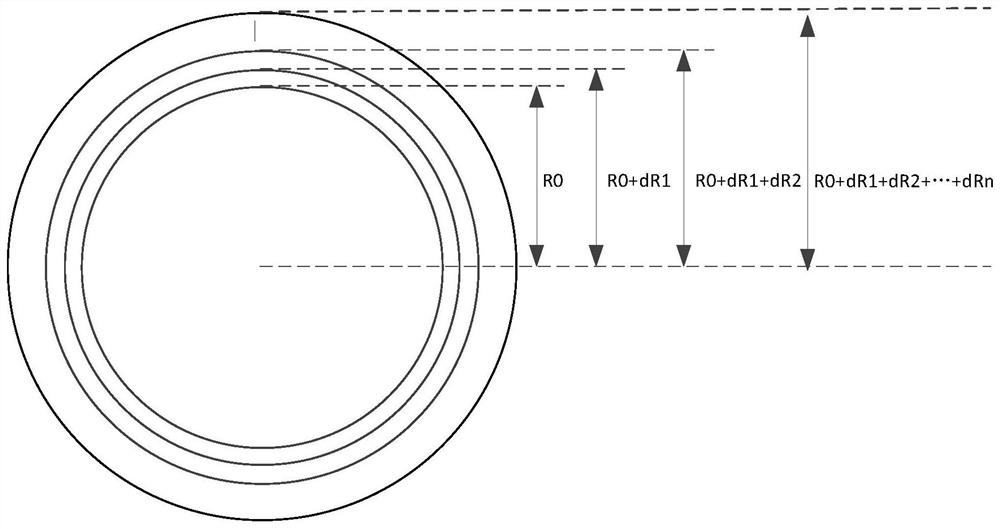

[0062] The firing frequency F depends on the image accuracy D, the angular velocity ω and the cylindrical radius R. When printing multiple layers on the same cylin...

Embodiment 2

[0110] see Figure 4 , the embodiment of the present invention provides a cylindrical surface printing control device 10, the device includes:

[0111] The first ignition frequency determination module 11 is configured to determine the ignition frequency of the nozzle according to the circumferential image accuracy, the cylindrical radius and the cylindrical angular velocity of the first preset layer, which is recorded as the first ignition frequency;

[0112] a first preset layer printing module 12, configured to print a first preset layer on the cylindrical surface according to the first ignition frequency;

[0113] The first radius change value acquisition module 13 is used to obtain the first radius change value of the cylindrical shape after printing the first preset layer;

[0114] The second ignition frequency determination module 14 is configured to determine the second ignition frequency according to the printing parameter and the first radius change value;

[0115]...

Embodiment 3

[0131] The embodiment of the present invention provides a control board 20 for printing control on a cylindrical surface, such as Figure 5 As shown, the control panel includes:

[0132] The main control device 21 is used to control the operation of the control board 20;

[0133] Cylindrical surface printing control device 10, the device 10 includes at least:

[0134] The first ignition frequency determination module 11 is configured to determine the ignition frequency of the nozzle according to the circumferential image accuracy, the cylindrical radius and the cylindrical angular velocity of the first preset layer, which is recorded as the first ignition frequency;

[0135] a first preset layer printing module 12, configured to print a first preset layer on the cylindrical surface according to the first ignition frequency;

[0136] The first radius change value acquisition module 13 is used to obtain the first radius change value of the cylindrical shape after printing the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com