Steel rail wheel structure under severe working conditions

A technology of rails and working conditions, applied in the field of rail wheels, can solve the problems of reducing the service life of rail wheels, easy-to-seize bearings, etc., and achieve the effects of cost saving, reduction of processing difficulty and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, but not all of the embodiments.

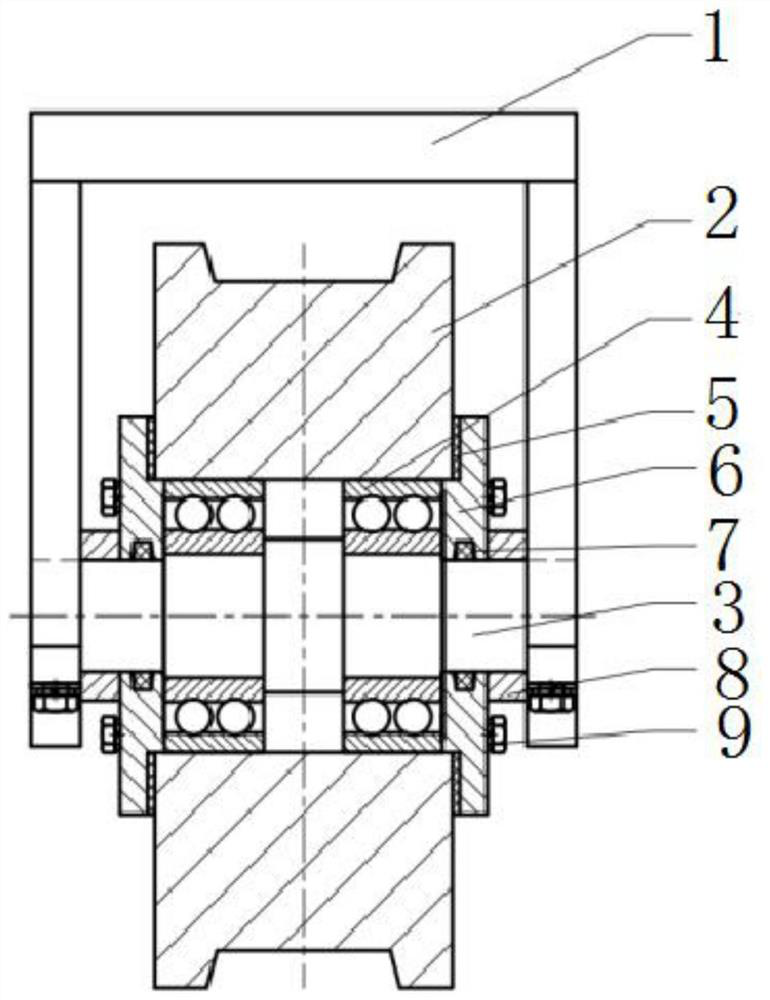

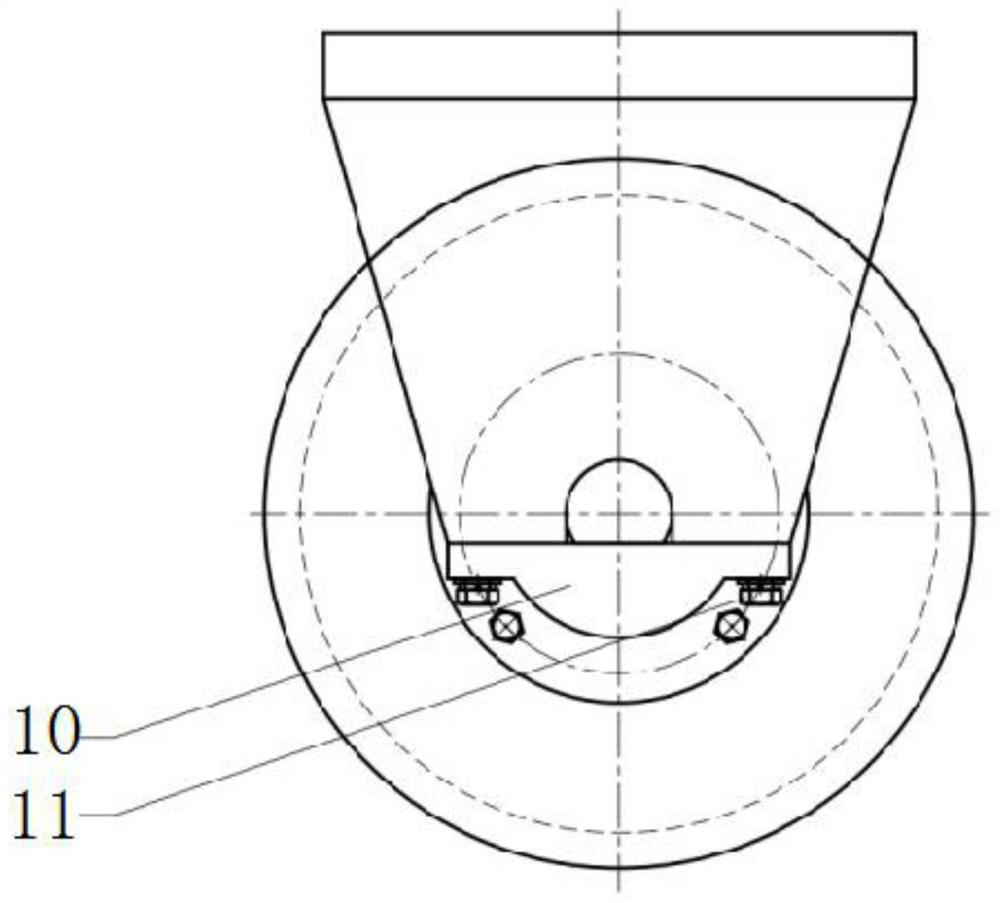

[0015] refer to Figure 1-2 , a rail wheel structure under severe working conditions, including a wheel base 1, a mandrel 3 is rotatably installed in the wheel base 1, a shaft sleeve 8 is sleeved on the mandrel 3, and a double dust cover is sleeved on the shaft sleeve 8 Row deep groove ball bearing 4, double row deep groove ball bearing 4 with dust cover is sleeved with rail wheel 2.

[0016] In the present invention, both sides of the rail wheel 2 are provided with end sealing plates 6 sleeved on the shaft sleeve 8 , and the two end sealing plates 6 are fixedly connected by the first connecting bolts 9 .

[0017] In the present invention,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com