A method for manufacturing and installing a pressure-stabilizing and damping body of a penstock steel pipe

A technology of penstock and installation method, which is applied in the direction of manufacturing tools, auxiliary devices, and ship lifting devices, and can solve problems such as noise and vibration of water delivery pressure pipes and valves on them, so as to achieve smooth and safe movement in place, and is conducive to dispersal Effects of simple loads and structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

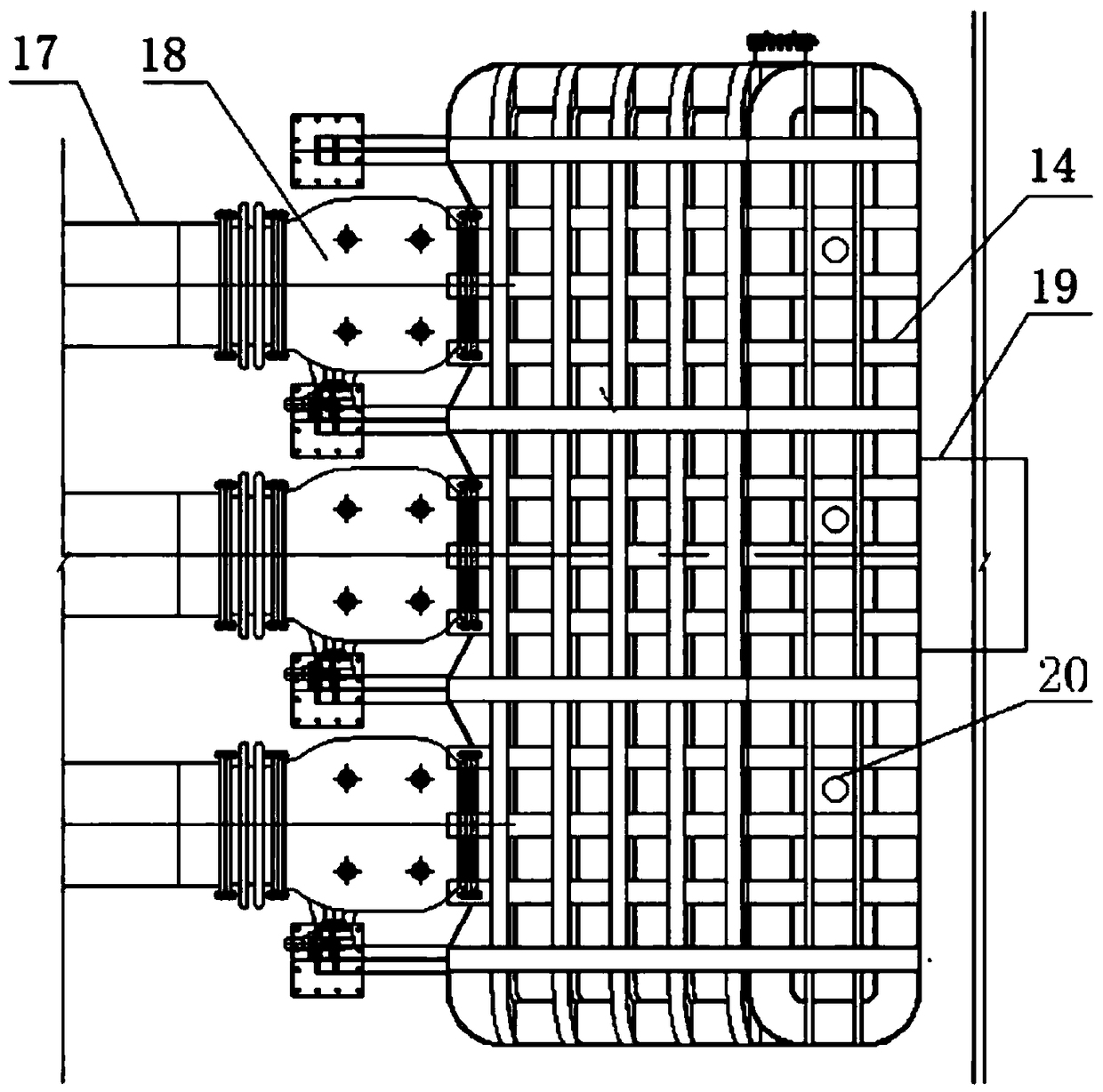

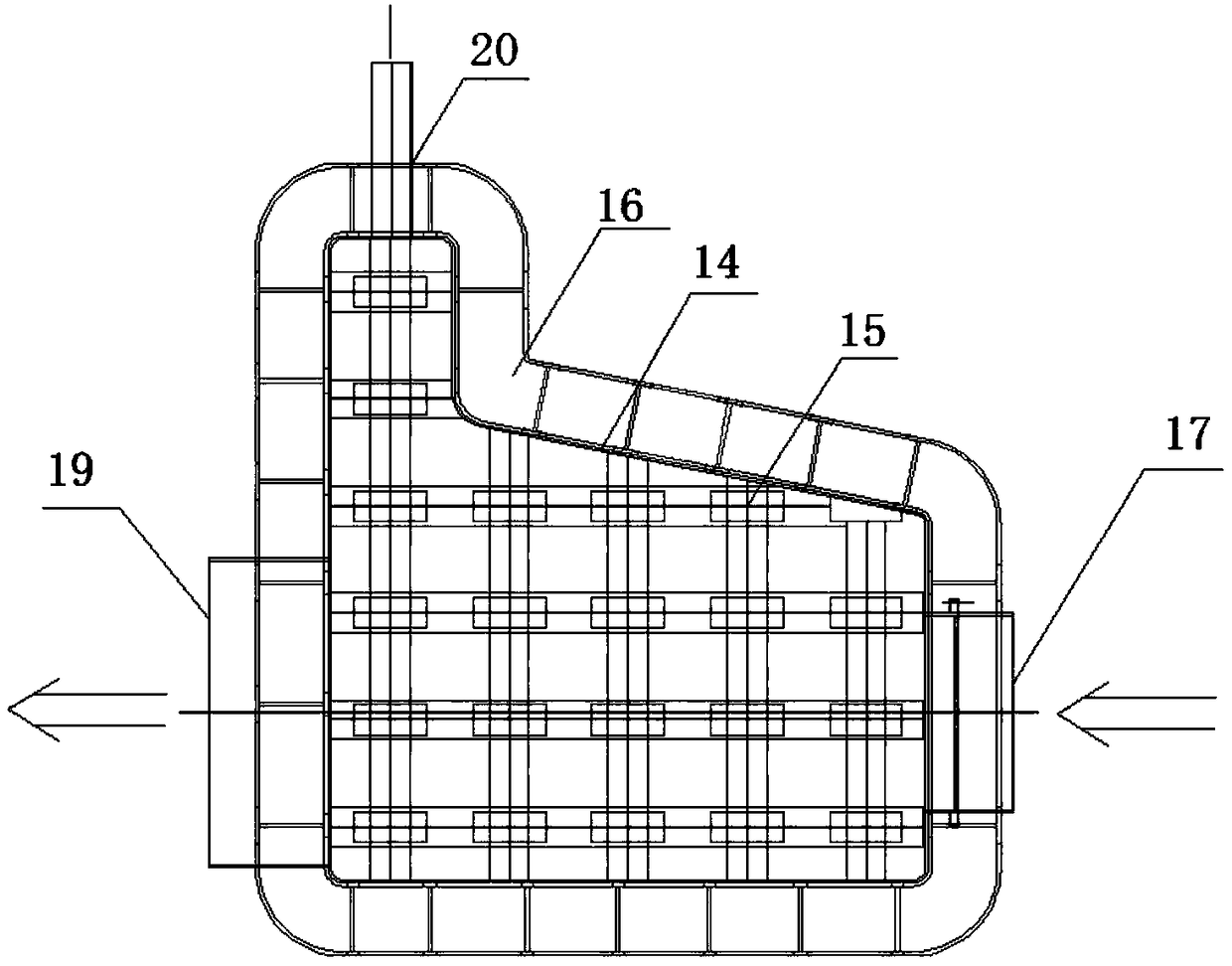

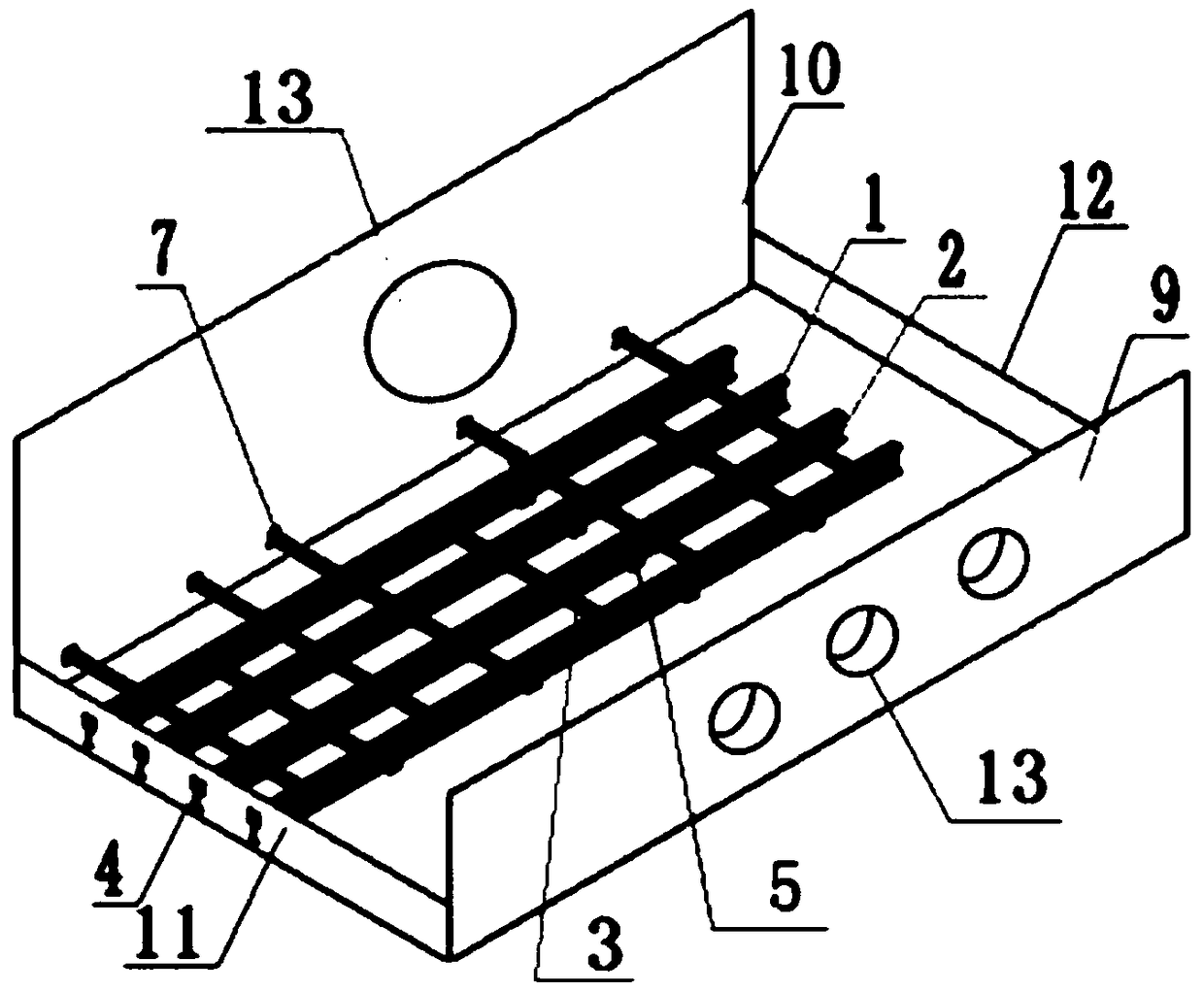

[0046] Such as Figure 1-2 As shown, a penstock steel pressure stabilizing and damping body includes a shell 14, an inner support beam system 15 that is located in the shell 14 and welded to the inner wall of the shell 14, and welded to the shell 14. Outer wall and grid-shaped outsourcing beam system 16; the top of the housing 14 is provided with a ventilation hole 20, and the downstream side of the housing 14 is provided with a water outlet communicating with the inner cavity of the housing 14. Three water inlets communicating with the inner cavity of the housing 14 are equidistantly arranged on the upstream side of the housing 14, and the inner support beam system 15 is in the form of a grid and has four columns, which are equidistantly distributed in the housing 14, and are all arranged along the water flow direction in the housing 14. The three water inlets are respectively connected to the water inlet steel pipes through three water filling valves 18, and the water outle...

Embodiment 2

[0049] Such as Figure 1-6 As shown, a method for manufacturing and installing a penstock steel pressure stabilizing and damping body, the manufacturing and installing method divides the described pressure stabilizing and damping body into several sub-block manufacturing units, and completes assembly, construction, transportation in the form of sub-block manufacturing units and hoisting, welding and connecting the sub-block manufacturing units in the lock chamber, completing the integral welding of the pressure stabilizing and damping body, and then installing through pipes, and finally welding and connecting with the water delivery pressure steel pipes and branch pipes.

[0050] The manufacturing and installation method specifically includes the following steps:

[0051] Step 1: Design division of block manufacturing units: using computer three-dimensional assisted analysis to divide the voltage stabilizing and damping body into six block manufacturing units;

[0052] Step 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com