Tension control device for continuous winding of yarn

A tension control and yarn technology, applied in the field of yarn, can solve the problems of poor yarn tension adjustment effect and inability to accurately adjust the tension, and achieve the effects of improving accuracy, avoiding knots and uniform tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

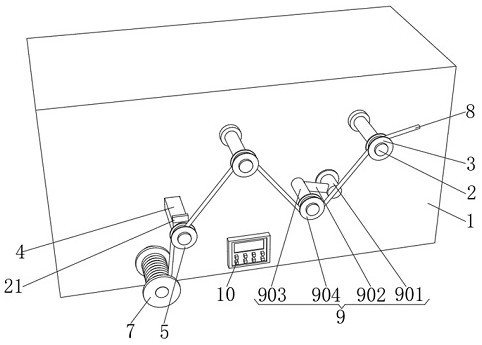

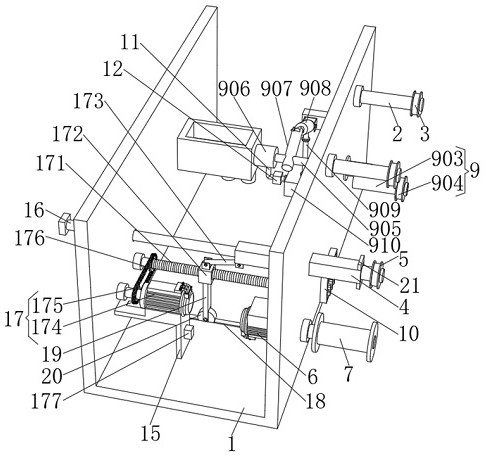

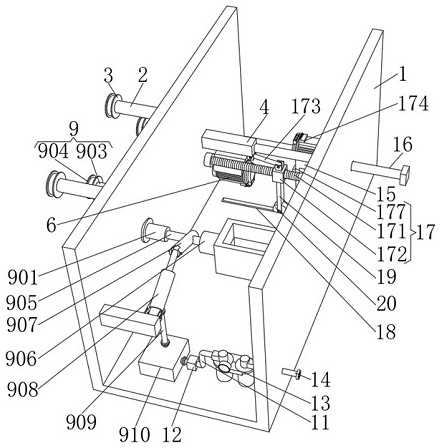

[0027] see Figure 1-6 , the present invention provides a technical solution: a tension control device for continuous yarn winding, comprising an installation frame 1, and two sets of fixed rods 2 are installed on the top of the front of the installation frame 1 to rotate along the left-right direction, and the fixed rods 2 are fixed on the A fixed guide wheel 3 is connected, a fixed rod 4 is inserted on the left side of the bottom of the front of the installation frame 1, and the fixed rod 4 is located on the left side of the fixed rod 2, and the front of the fixed rod 4 is fixedly connected with the adjustment wheel 5 through the cable rod. The frame 1 is provided with a reciprocating mechanism 17 that is used in conjunction with the adjusting wheel 5. The design of the reciprocating mechanism 17 uses the second motor 174 to provide a driving source, which can push the adjusting wheel 5 to reciprocate according to the line distance required by the product, so that the yarn T...

Embodiment 2

[0029] see Figure 1-6, the present invention provides a technical solution: a tension control device for continuous yarn winding, comprising an installation frame 1, and two sets of fixed rods 2 are installed on the top of the front of the installation frame 1 to rotate along the left-right direction, and the fixed rods 2 are fixed on the A fixed guide wheel 3 is connected, a fixed rod 4 is inserted on the left side of the bottom of the front of the installation frame 1, and the fixed rod 4 is located on the left side of the fixed rod 2. The fixed rod 4 has a square structure, which can prevent the fixed rod 4 from rotating when moving. The front of the fixing rod 4 is fixedly connected with the adjusting wheel 5 through the cable rod, and the fronts of the top and bottom of the fixing rod 4 are fixedly connected with baffles 21, which can limit the front of the fixing rod 4 and prevent the fixing rod 4 from entering the installation completely. Frame 1, it is easy to make th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com