Drip irrigation pipe rolling system

A drip irrigation tube and rewinding reel technology is applied in the direction of conveying filamentous materials, thin material handling, transportation and packaging, etc., which can solve the problems of increasing processing costs, affecting production efficiency, and different winding tightness, etc. Convenience and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

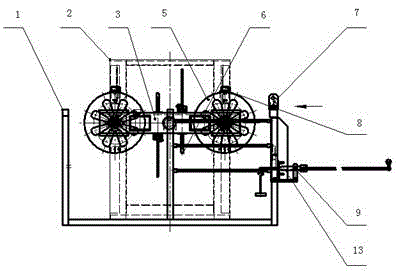

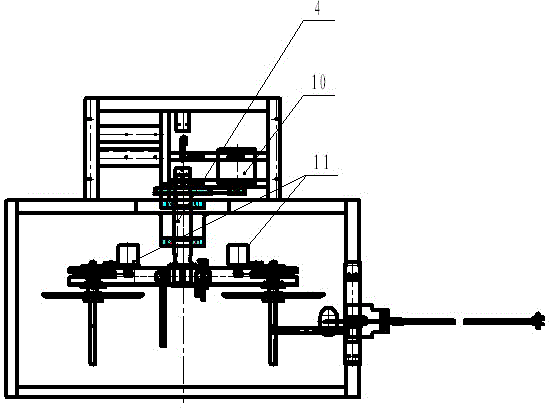

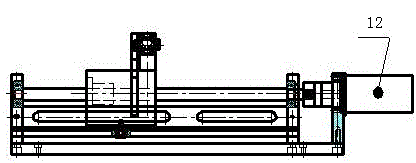

[0014] Embodiment: a kind of drip irrigation pipe winding system (see Figure 1 to Figure 3 ), which is characterized in that it includes a main frame 1, a rotating arm 3, a main shaft 4, two winding motors 11, two winding reels 5, a tensioning rod 9, a cable puller 7, a tube puller 6, and a tube gripper 8. Electric box 2, rotating motor 10 and control unit; the main shaft 4 is installed on the main frame 1, the rotating arm 2 is fixed on the main shaft 4, and the main shaft 4 is connected with the rotating motor 10; the winding motor 11 is installed on the rotating On the arm 3, and connected to the reel 5; the potentiometer 13 is installed inside the tensioning rod 9; the cable controller 7 is connected to the cable servo motor 12 and installed on the main frame 1; , a potentiometer 13, and a cable servo motor 12 are all connected to the control unit; the reel 5 is provided with a gripper 8;

[0015] The main shaft 4 is connected with the rotating electrical machine 10 thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com