Method for determining allowable bearing capacity of railroad bed

A railway and foundation technology, applied in infrastructure engineering, foundation structure testing, construction, etc., can solve problems such as inaccuracy, insufficient theoretical basis, and disputes, and achieve the effect of precise design, clear concept, and sufficient theoretical basis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

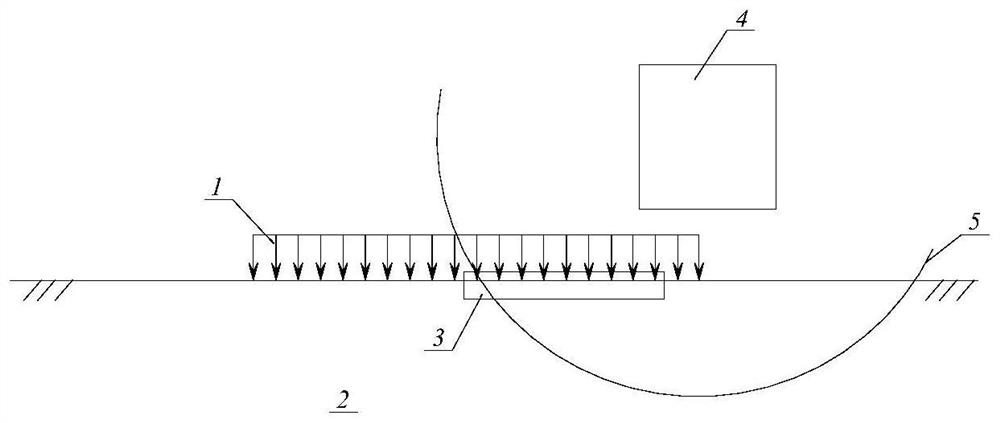

[0037] A high-speed railway is a double-track railway, with a design speed of 350km / h, a subgrade width of 13.6m, and an average fill height of 6m in sections DK50+300~DK51+400. The method of the present invention is used to determine the allowable bearing capacity of the substrate.

[0038] The specific steps are:

[0039] ①According to the geological prospecting report: the basement stratum in this section is soft plastic clay with a weight of 18kN / m 3 , the cohesion is 10kPa, the internal friction angle is 10°, and the filler weight is 20kN / m 3 .

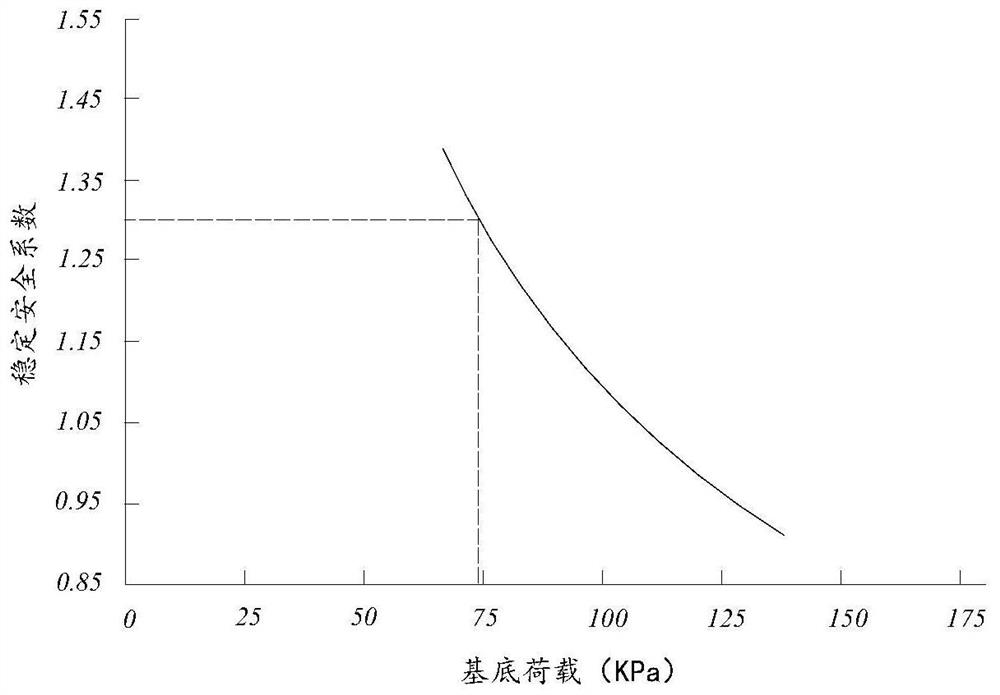

[0040] ②The design speed of the railway involved is 350km / h, and the Swedish slicing method is to be adopted for the calculation. According to the specification, it can be seen that [Fs]≥1.30.

[0041] ③The width of the subgrade surface is 13.6m, the average filling height is 6m, and the slope ratio of the embankment is 1:1.5. Therefore, the initial value of the base load p can be taken as 1 / 2×20×6=60kPa, and the base width B ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com