Alkaline battery sealing body structure

An alkaline battery, sealing body technology, applied in structural parts, battery pack parts, circuits, etc., can solve problems such as poor anti-drop performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

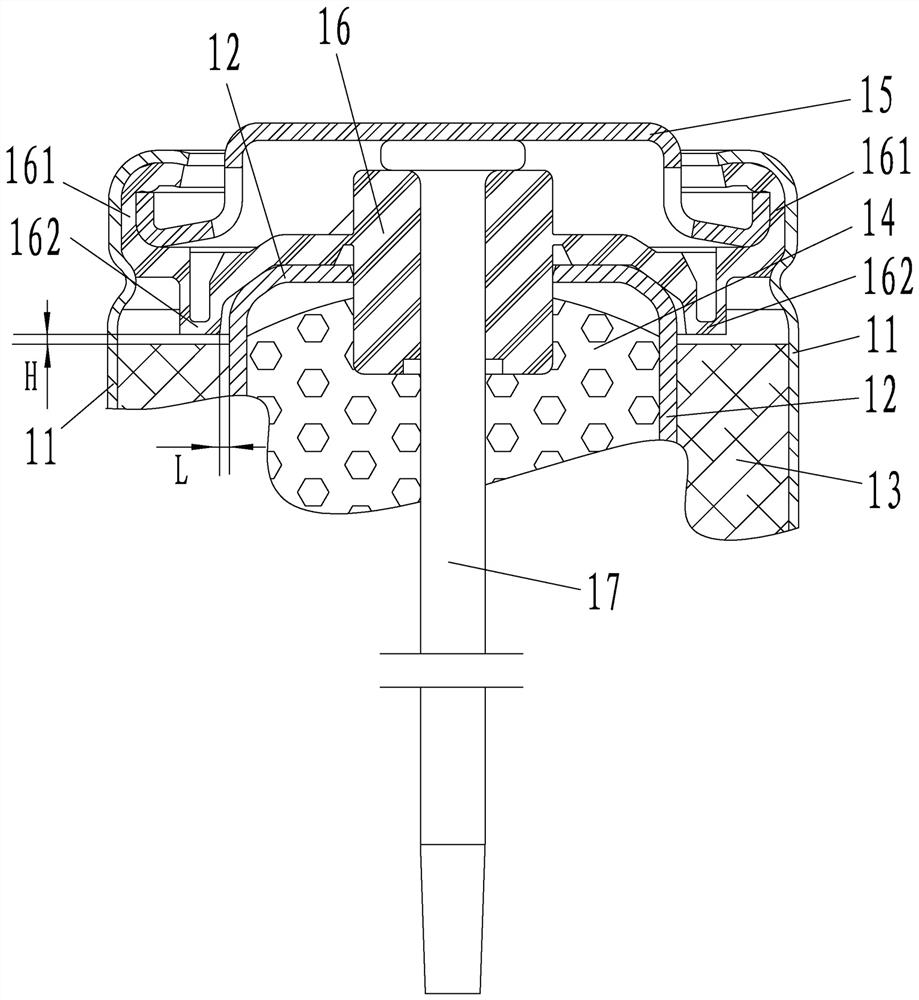

[0011] like figure 1 As shown, an alkaline battery sealing body structure is installed in an alkaline battery, the positive steel shell 11 of the alkaline battery is a cylindrical structure with only the upper end open, and the positive steel shell 11 is coaxially sleeved with an isolation tube 12. The upper edge of the separator tube 12 is lower than the upper edge of the positive electrode steel shell 11, the annular cavity between the positive electrode steel shell 11 and the separator tube 12 is filled with the pressed positive electrode ring 13, and the separator tube 12 is filled with negative electrode material 14. The bottom surface of the sealing body structure 16 is attached to the upper edge of the isolation tube 12 and the upper end opening of the isolation tube 12 is closed. The upper end opening of the positive steel case 11 is embedded with a negative electrode cover 15 to seal the upper end of the positive steel case 11. There is an annular gap between the oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com