Method for preparing fluidizing chlorination furnace charge by granulating fine-grained titanium-rich material

A technology of boiling chlorination furnace and titanium-rich material, applied in the direction of titanium halide, etc., can solve problems such as the inability to use boiling chlorination furnace, and achieve the effects of easy mass production, low granulation cost and high drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

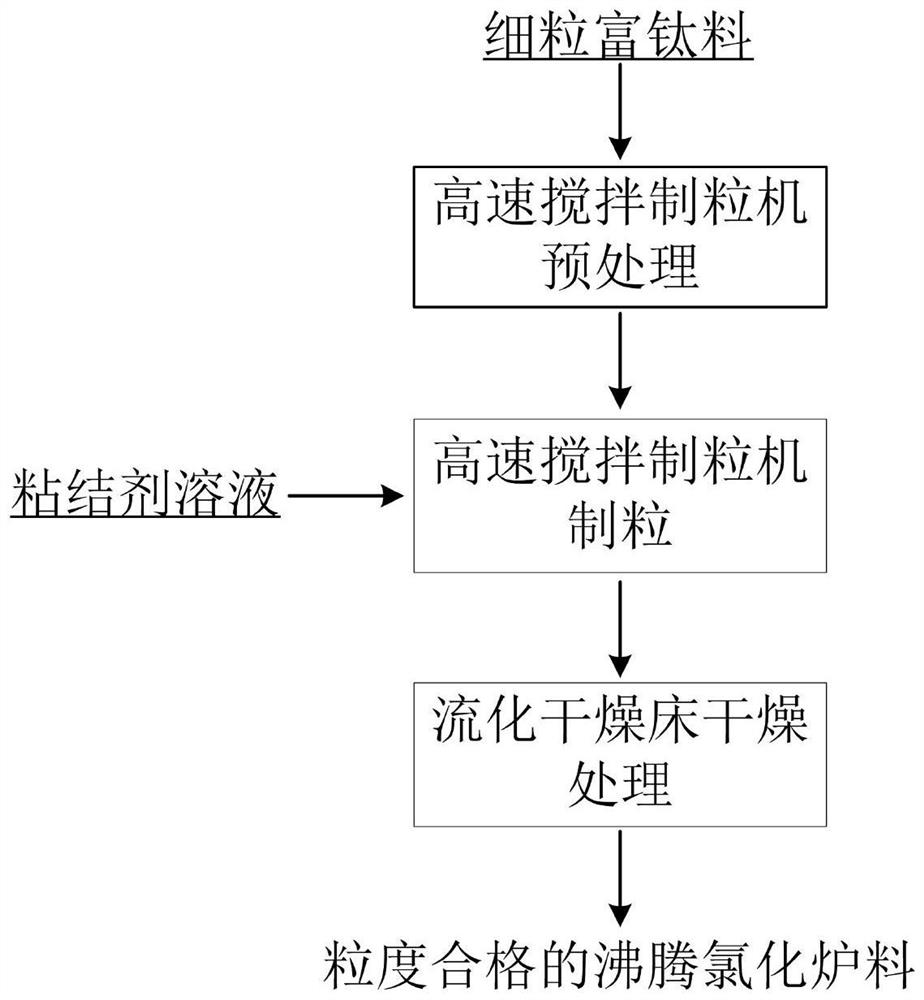

Image

Examples

Embodiment 1

[0032] Weigh 500g of fine-grained titanium raw material with a particle size of less than 150μm and put it into the granulation bucket of a high-speed stirring granulator. Set the stirring paddle speed: 300 rpm, stirring time: 2 minutes, and stir the material evenly. The prepared binder solution was evenly sprayed into the fine-grained titanium raw material in the form of atomization through a spray gun, and the rotating speed of the stirring paddle was set: 200 rpm; After the granulation is completed, put the granules into the fluidized bed dryer, set the drying wind speed: 10m / s, the drying temperature: 300°C, and the drying time: 30 minutes. The particle size distribution of the dried product is between 150 and 1000 μm, accounting for 60%, particles larger than 1000 μm accounting for 20%, and particles smaller than 150 μm accounting for 20%.

Embodiment 2

[0034]Weigh 500g of fine-grained titanium raw material with a particle size of less than 150μm and put it into the granulation bucket of a high-speed stirring granulator. Set the stirring paddle speed: 300 rpm, stirring time: 2 minutes, and stir the material evenly. The prepared binder solution was evenly sprayed into the fine-grained titanium raw material in the form of atomization through a spray gun, and the speed of the stirring paddle was set: 200 rpm; After the granulation is completed, put the granules into the fluidized bed dryer, set the drying wind speed: 10m / s, the drying temperature: 300°C, and the drying time: 30 minutes. The particle size distribution of the dried product is between 150 and 1000 μm, accounting for 75%, the particle size larger than 1000 μm accounting for 20%, and the particle size smaller than 150 μm accounting for 5%.

Embodiment 3

[0036] Weigh 500g of fine-grained titanium raw material with a particle size of less than 150μm and put it into the granulation bucket of a high-speed stirring granulator. Set the stirring paddle speed: 300 rpm, stirring time: 2 minutes, and stir the material evenly. The prepared binder solution was evenly sprayed into the fine-grained titanium raw material in the form of atomization through a spray gun, and the speed of the stirring paddle was set: 200 rpm; After the granulation is completed, put the granules into the fluidized bed dryer, set the drying wind speed: 8m / s, the drying temperature: 300°C, and the drying time: 30 minutes. The particle size distribution of the dried product is between 150 and 1000 μm, accounting for 80%, particles larger than 1000 μm accounting for 17%, and particles smaller than 150 μm accounting for 3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com