High tower graining method for producing composite (mixed) fertilizer

A high-tower granulation and granulation technology, which is applied in the direction of fertilizer forms, fertilization devices, fertilizer mixtures, etc., can solve the problems of unadjustable viscosity, poor product quality, and product variety restrictions, and achieve reduced steam loss and high pelleting rate , the effect of many product varieties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

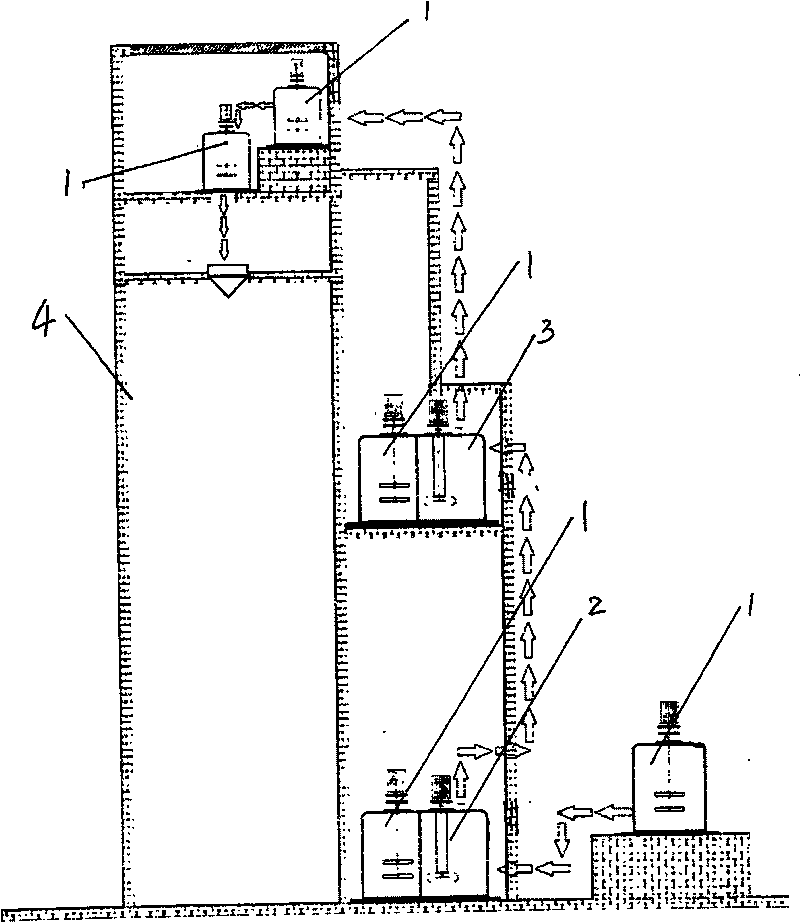

[0011] Reference figure 1 ; Transport the liquid material (liquid urea or liquid ammonium nitrate) to the controllable mixing buffer device 1, add normal temperature solid material potassium sulfate or potassium chloride to mix, according to the ratio of the normal temperature solid material to the liquid material, through the controllable mixing buffer Device 1, to keep the temperature of the suspension material within a certain range, pump 2 to the controllable mixing buffer device 1 at the top of the prilling tower 4, and add normal temperature solid material phosphate fertilizer (monoammonium phosphate or diammonium phosphate), The temperature of the material is controlled by the controllable mixing buffer device 1 to ensure its proper granulation temperature, and finally the suspension material enters the granulator for granulation.

[0012] Reference figure 1 As shown, when the pump 1 for transporting ground suspension materials cannot be transported to the top of the prilli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com