Method for synergistically curing heavy metal Cr-Ni-Mn in stainless steel slag

A cr-ni-mn, stainless steel slag technology, applied in the field of synergistic solidification of heavy metals Cr, Ni, Mn, can solve the problems of affecting the stability and safety of building materials, limit the application field and utilization rate of stainless steel slag, and achieve no Harmful treatment, large amount of introduction, and the effect of reducing environmental pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

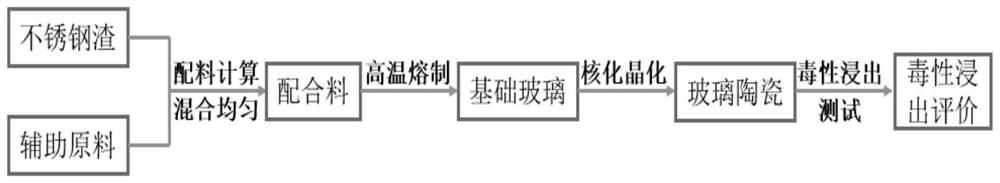

[0042] A method for synergistic solidification of heavy metals Cr-Ni-Mn in stainless steel slag, the specific steps are as follows:

[0043] (1) Preparation of the mixture: the design uses diopside as the main crystal phase, and different SiO 2 / Al 2 O 3 The basic glass formulation (see Table 1 for the basic composition of glass ceramics). Using stainless steel slag as the main raw material (main chemical composition is shown in Table 2), and the addition amount is 60% (wt%), with an appropriate amount of auxiliary raw materials such as quartz sand, alumina, soda ash, etc., calculate the raw material composition of glass ceramics (raw material composition See Table 3), weigh the raw materials according to the raw material composition of the glass ceramics and mix them uniformly.

[0044] Table 1 Different SiO 2 / Al 2 O 3 The basic composition formula of glass ceramics (wt.%)

[0045]

[0046] Attached: # TO x : T=Cr, Ni, Mn (ie TO x The content of : Cr 2 O 3 , N...

Embodiment 2

[0060] At the same time, only the crystallization heat treatment temperature in step (3) was changed (the crystallization temperature was 830° C.), and other conditions such as the basic component formula, raw material composition and preparation method of the glass ceramics were the same as those in Example 1, and the results obtained under different heat treatment temperatures were obtained. glass ceramics.

[0061] Leaching test of heavy metals in glass ceramics: Toxic metal testing of glass ceramics is carried out with reference to the standard HJ / T299-2007 "Toxic Leaching Method: Sulfuric Acid and Nitric Acid Method". 0-0.15ppm and 0.26-0.87ppm (eg Figure 4 a), all lower than the standard values of 15ppm (Cr), 5ppm (Ni) and 5ppm (Mn).

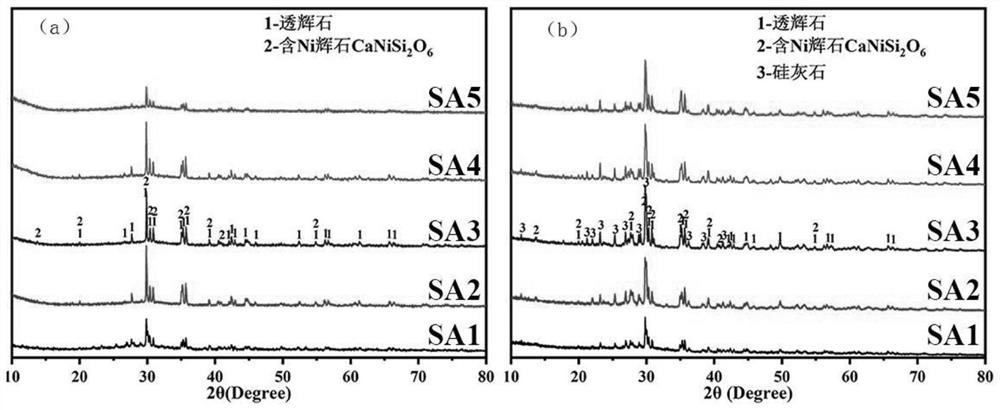

[0062] The X-ray diffraction pattern of the glass ceramics obtained in the present embodiment is analyzed, and the results are as follows image 3 (a).

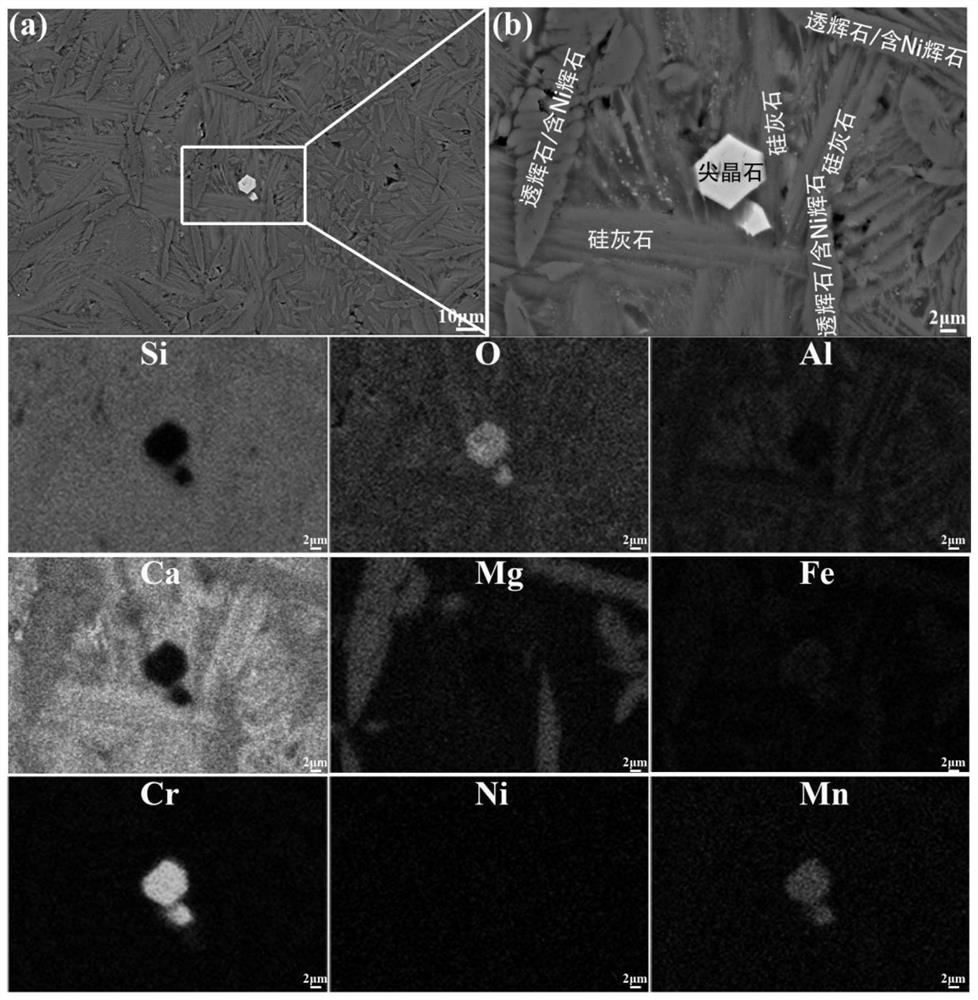

[0063] Depend on image 3 (a) It can be seen that the main crystal phases of t...

Embodiment 3

[0065] A method for synergistic solidification of heavy metals Cr-Ni-Mn in stainless steel slag, the specific steps are as follows:

[0066] (1) Preparation of mixture: Design the basic glass formula of diopside / pyxene phase, wherein the weight percentage of each component is composed of: SiO 2 47%, Al 2 O 3 6.3%, CaO 28.5%, MgO 4.2%, CaF 2 3.2%, Fe 2 O 3 3.6%, Na 2 O+K 2 O 2.6%, TO X (T=Cr, Ni, Mn) 2.1%, Rest (P 2 O 5 , TiO 2 , BaO and other impurity components) 2.5%. Using stainless steel slag as the main raw material (see Table 2 for its main chemical composition), and the addition amount of 70% (wt%), with an appropriate amount of auxiliary raw materials such as quartz sand and soda ash, calculate the raw material composition of glass ceramics (see Table 4 for raw material composition) ), weigh the raw materials according to the raw material composition of glass ceramics and mix them evenly;

[0067] Table 4 Raw material composition of glass ceramics (wt.%) ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap