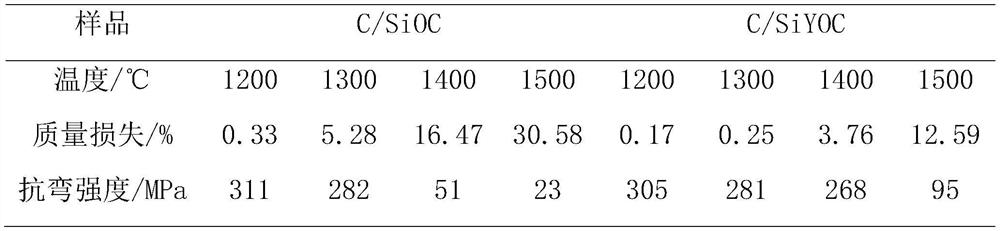

Carbon fiber reinforced SiYOC composite material and preparation method thereof

A composite material and carbon fiber technology, which is applied in the field of carbon fiber reinforced SiYOC composite material and its preparation, can solve the problems of limiting C/SiOC composite material's high temperature resistance, performance degradation, structural instability, etc., achieve the average bond length, improve the introduction The effect of improving the quantity and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A kind of preparation method of carbon fiber reinforced SiYOC composite material, comprises the following steps:

[0023] (1) Impregnation: Prepare a 2.5-dimensional braid and place it under a vacuum condition with a pressure of less than 500 Pa, and impregnate a modified precursor solution with a Y content of 10% of the mass of the silicone resin for 3 hours; the Y-modified silicone resin The precursor solution is a mixed sol of yttrium sol and silicone resin ethanol solution, wherein the yttrium sol is made of Y(NO 3 ) 2 ·6H 2 O is dissolved in ethanol, the mass ratio of silicone resin and ethanol in the silicone resin ethanol solution is 2:10, and the silicone resin is a small molecular weight methyl silicone resin (MK);

[0024] (2) Curing: place the impregnated carbon fiber preform at 60°C for 72h until it gels, and then cross-link and cure the gelled preform at 200°C for 6h;

[0025] (3) Pyrolysis: The cross-linked and solidified carbon fiber prefabricated part...

Embodiment 2

[0030] A kind of preparation method of carbon fiber reinforced SiYOC composite material, comprises the following steps:

[0031] (1) Impregnation: Prepare a three-dimensional five-directional braid and place it under a vacuum condition with a pressure less than 500 Pa, and impregnate it with a modified precursor solution whose Y content is 50% of the mass of the silicone resin for 2 hours; the Y-modified silicon The resin precursor solution is a mixed sol of yttrium sol and silicone resin ethanol solution, wherein the yttrium sol is made of Y(NO 3 ) 2 ·6H 2 O is dissolved in ethanol, the mass ratio of silicone resin and ethanol in the silicone resin ethanol solution is 5:10, and the silicone resin is a small molecular weight methyl silicone resin (MK);

[0032] (2) Curing: The impregnated carbon fiber is pre-preliminarily placed at 70°C for 36h until it gels, and then the gelled preform is cross-linked and cured at 150°C for 8h;

[0033] (3) Cracking: The cross-linked and s...

Embodiment 3

[0038] A kind of preparation method of carbon fiber reinforced SiYOC composite material, comprises the following steps:

[0039](1) Impregnation: Prepare a three-dimensional needle felt and place it under a vacuum condition with a pressure of less than 500Pa, and impregnate it with a modified precursor solution with a Y content of 15% of the mass of the silicone resin for 4 hours; the Y-modified silicone resin The precursor solution is a mixed sol of yttrium sol and silicone resin ethanol solution, wherein the yttrium sol is made of Y(NO 3 ) 2 ·6H 2 O is dissolved in ethanol, the mass ratio of silicone resin and ethanol in the silicone resin ethanol solution is 3:10, and the silicone resin is a small molecular weight methyl silicone resin (MK);

[0040] (2) Curing: The impregnated carbon fiber preform was left standing at 75°C for 30h until it gelled, and then the gelled preform was crosslinked and cured at 250°C for 4h;

[0041] (3) Cracking: The cross-linked and cured car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com