Efficient heat exchanger for medium-deep geothermal energy

A deep-seated, heat exchanger technology, applied in geothermal energy, geothermal energy power generation, geothermal collectors, etc., can solve the problems of high utilization cost of heat exchangers, low continuous heat extraction capacity, poor system stability, etc. The effect of enhancing the heat extraction capacity, prolonging the heat exchange time and improving the heat exchange capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

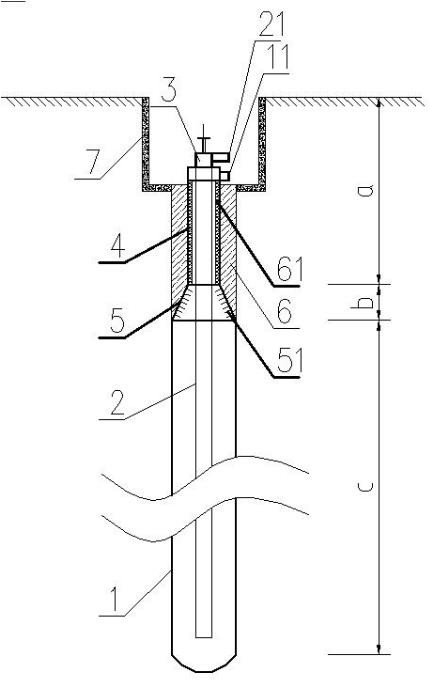

[0027] like Figure 1-3 As shown in the figure, a high-efficiency heat exchanger for middle and deep geothermal energy is set below the ground as a whole, with an inspection hole 7 at the top, and the inspection hole 7 is 2500cm~3000cm away from the ground, which is conducive to the installation of the heat exchanger and the connection of pipes, and does not affect the use of the ground. Function.

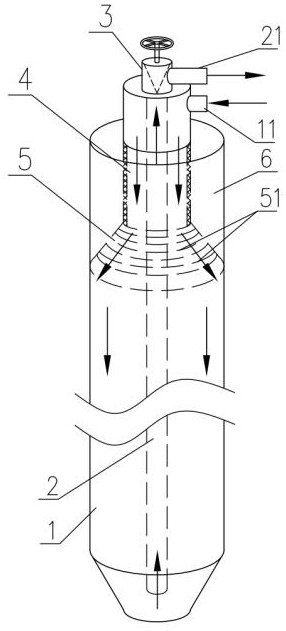

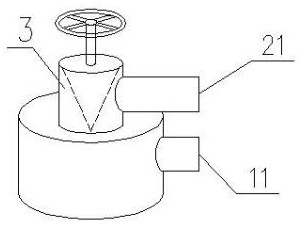

[0028] The high-efficiency heat exchanger includes an outer tube, a central tube 2, and a flow control liquid separator 3. The central tube 2 is coaxially arranged in the outer tube, and the flow control liquid separator 3 is arranged above the central tube 2. The flow control liquid separator 3 is the same as the The central pipe 2 and the heat preservation pipe 4 are connected; the outer pipe is divided into upper, middle and lower sections, which are the heat preservation pipe 4, the conversion pipe 5 and the heat exchange pipe 1 in order from top to bottom.

[0029] Specifical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com