Device and method for testing sealing performance of rubber O-shaped ring

A test device and ring sealing technology, which is applied in the direction of machine sealing ring testing, liquid tightness measurement using liquid/vacuum degree, etc., can solve the problems of inaccurate test results and systematic reduction of liquid volume, and achieve convenient operation and small size. The effect of small size and high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

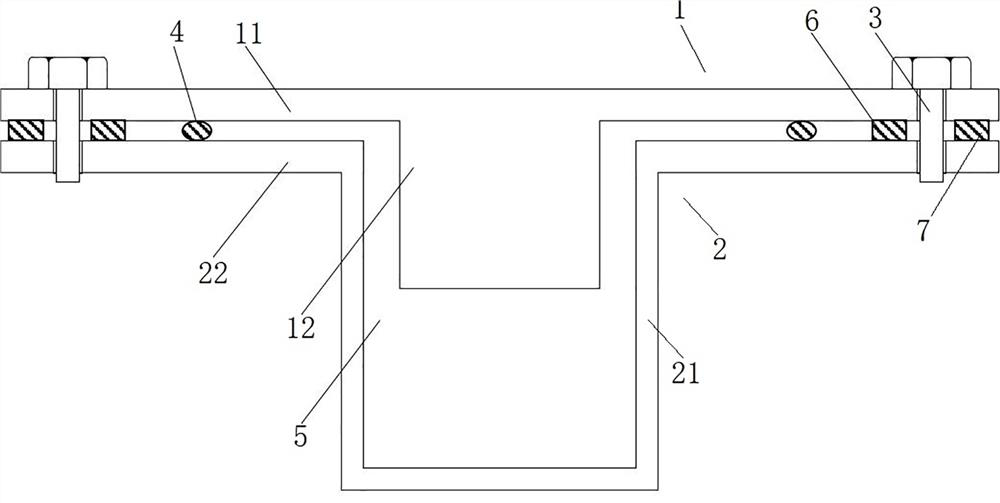

[0040] Embodiment 1. In this embodiment, as Figure 1 to Figure 3 As shown in the figure, a rubber O-ring sealing performance test device includes an upper pressure block 1 and a lower base 2 that are matched and installed. The upper pressure block 1 and the lower base 2 are fixed by fasteners 3. The said The rubber O-ring 4 is arranged between the upper pressing block 1 and the lower base 2 , and a compression cavity 5 is formed between the upper pressing block 1 , the lower base 2 and the rubber O-ring 4 .

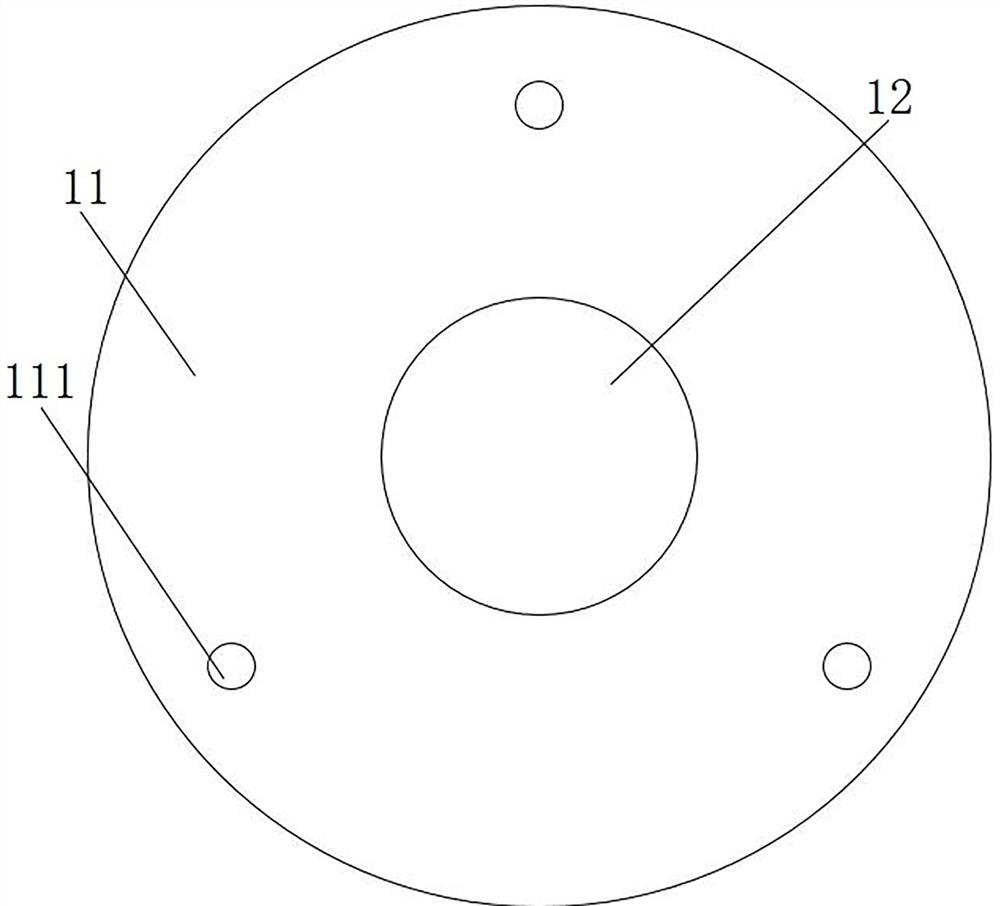

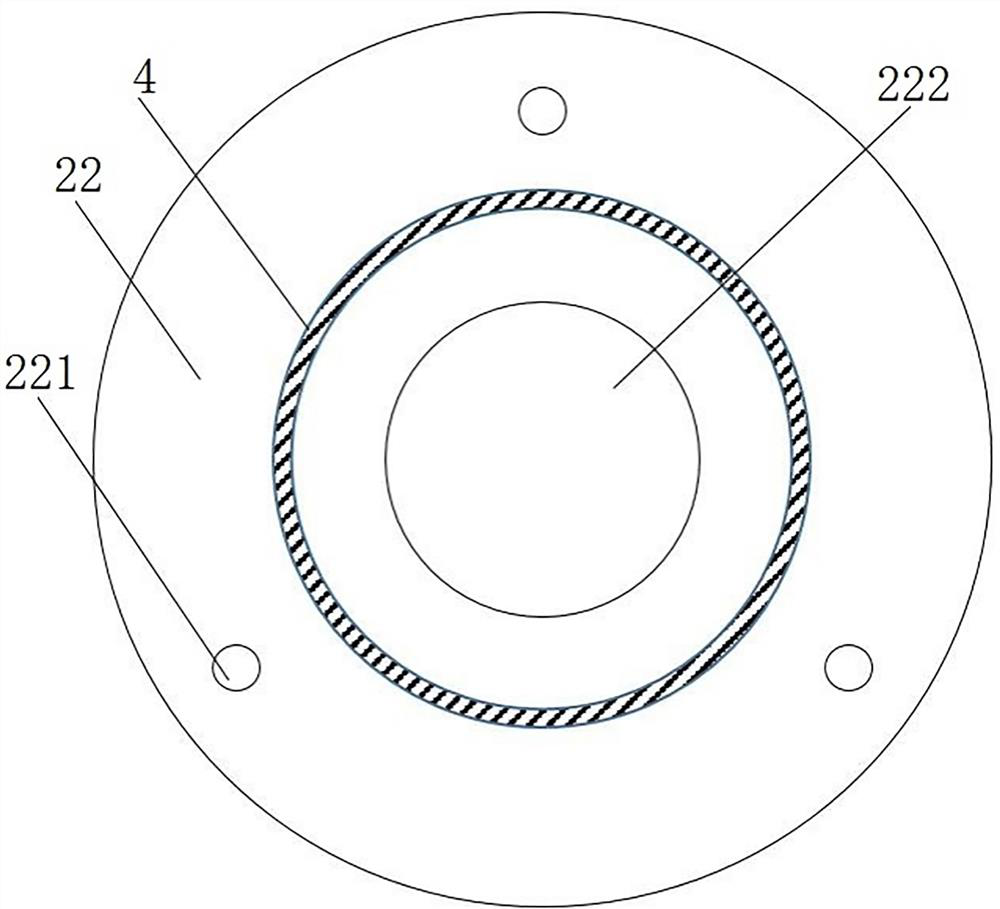

[0041] This embodiment is further configured as follows: the upper pressing block 1 and the lower base 2 are both made of an integral molding structure, and the upper pressing block 1 includes a pressing plate 11 and a protrusion 12 fixed at the center of the pressing plate; the lower base 2 It includes a main body 21 , and the outer side of the upper end of the main body 21 has a flange plate 22 extending outward; the rubber O-ring 4 is located on the flange plate 22 .

...

Embodiment 2

[0052] Embodiment 2. This embodiment provides a test method for a rubber O-ring sealing performance test device, which includes the following steps:

[0053] S1. Measure and calculate the volume V of the compression cavity 5 formed after the rubber O-ring 4 is installed between the upper pressing block 1 and the lower base 2;

[0054] S2. Turn the opening of the concave cavity 222 of the lower base 2 upward, add the test liquid for the specified test, and add a volume of V 液 ;

[0055] S3. Place the rubber O-ring 4 to be tested on the flange plate 22 of the lower base 2 to ensure that the opening of the concave cavity 222 is located inside the rubber O-ring 4, and the center of the rubber O-ring 4 The cylindrical central axis of the cavity 222 is concentric;

[0056] S4, place the first limit ring 6 and the second limit ring 7 at the three threaded holes 221 of the lower base 2 to ensure that the threaded holes 221 are located between the first limit ring 6 and the second li...

Embodiment 3

[0064] Embodiment 3. This embodiment further increases the setting of oil pressure parameters on the basis of Embodiment 2, including the following steps:

[0065] S1. Measure and calculate the volume V of the compression cavity 5 formed after the rubber O-ring 4 is installed between the upper pressing block 1 and the lower base 2;

[0066] S2. Move the opening of the concave cavity 222 of the lower base 2 upward, and add a fixed percentage X% of the test liquid on the basis of the concave cavity 222, and add a liquid volume of V 液 (1+X%);

[0067] S3. Place the rubber O-ring 4 to be tested on the flange plate 22 of the lower base 2 to ensure that the opening of the concave cavity 222 is located inside the rubber O-ring 4, and the center of the rubber O-ring 4 The cylindrical central axis of the cavity 222 is concentric;

[0068] S4, place the first limit ring 6 and the second limit ring 7 at the three threaded holes 221 of the lower base 2 to ensure that the threaded holes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com