Industrial process minimum-maximum optimization fault-tolerant control method based on reinforcement learning

An industrial process and reinforcement learning technology, applied in electrical program control, comprehensive factory control, etc., can solve problems such as inability to achieve control goals, achieve good control effects, maintain life and property safety, and widen the effect of actuator fault range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

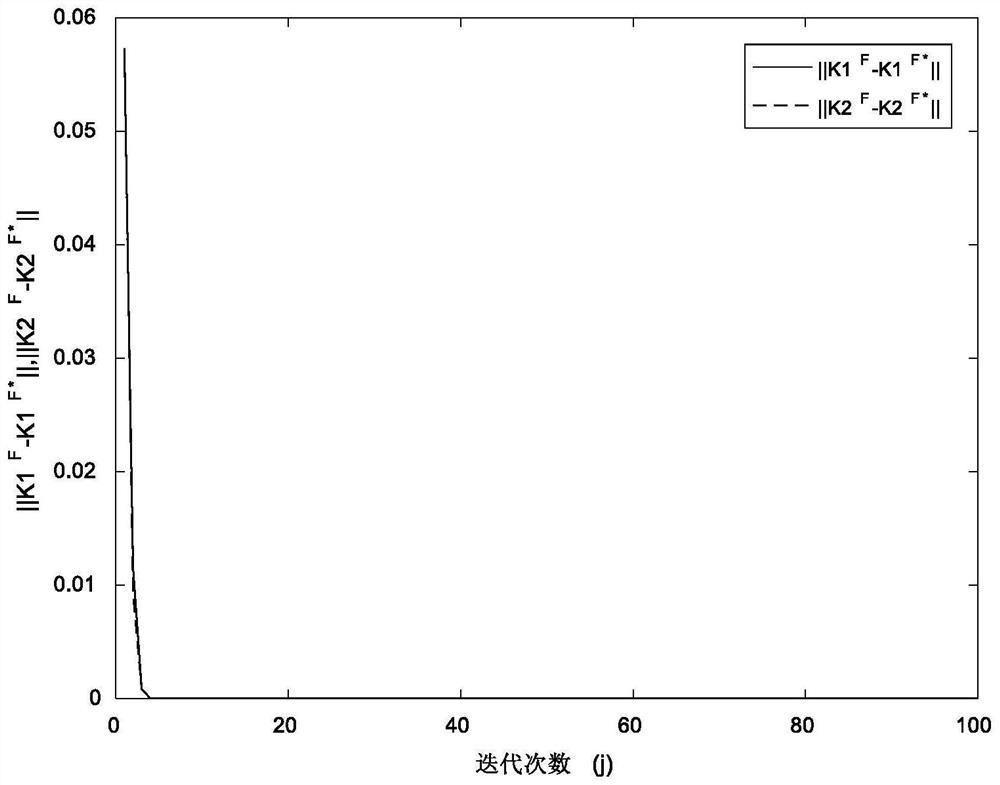

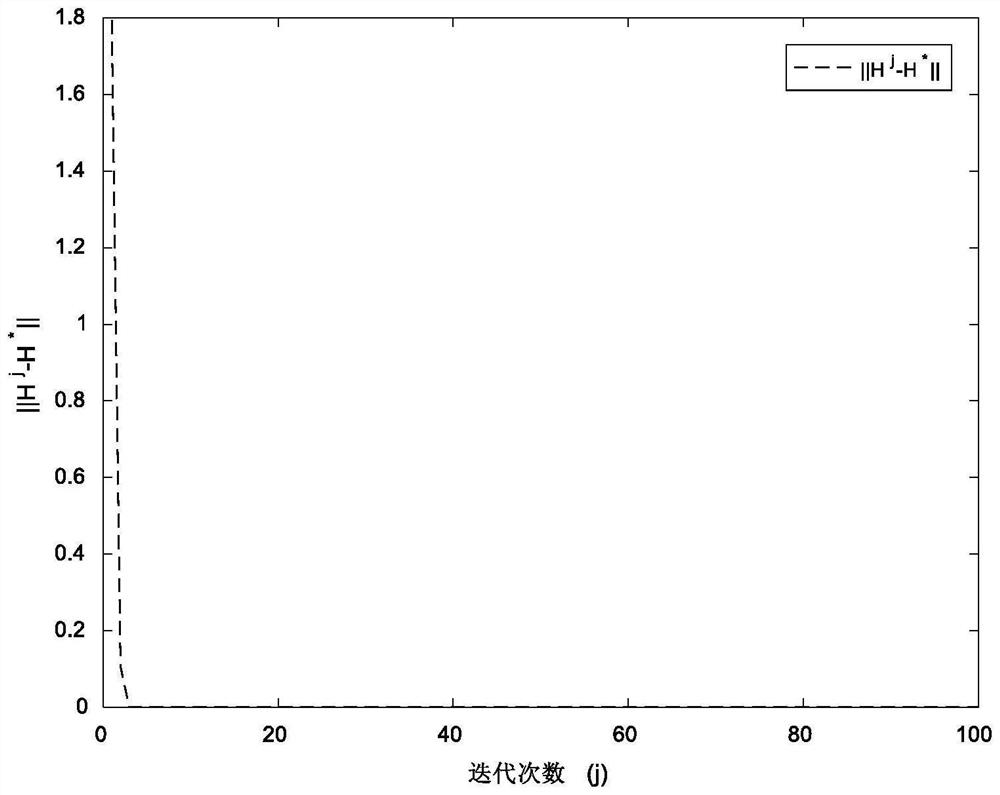

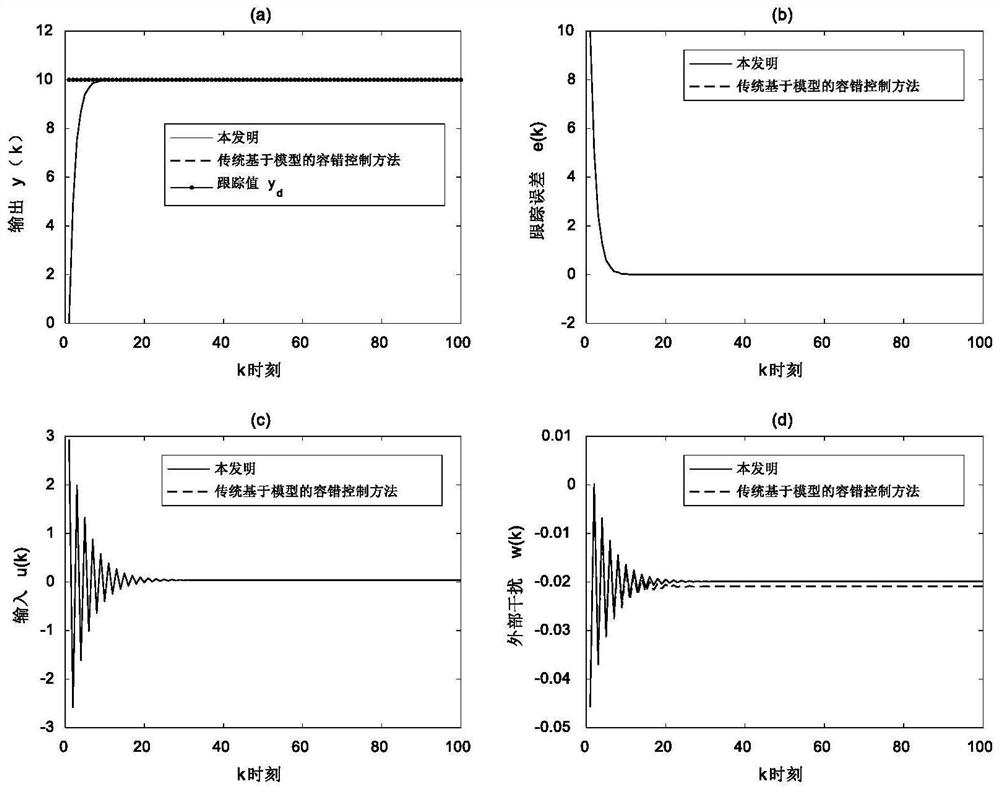

Examples

Embodiment 1

[0052] The present embodiment uses an injection molding process to specifically illustrate the method of the present invention. The injection molding process is the process of converting plastic pellets into various products, which mainly includes three stages: injection molding, pressure holding, and cooling molding. In order to ensure the quality of the products produced by the injection molding process and the production efficiency of the products, the relevant process variables should be required to change as much as possible according to the desired set values in each production stage. In the production process, since the injection speed has a great influence on the quality of the final product, it is necessary to control the injection speed with high precision in the injection molding stage, and the corresponding variables should be controlled to a given set value. The injection velocity response of the proportional valve can be identified as an autoregressive model: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com