Automatic assembling clamp for automobile door ring tailored blank laser welding steel plates and operation method

A technology of laser tailor welding and steel plate, which is applied in laser welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of increasing development and test costs, unable to meet the needs of flexible production, etc., and meet the needs of experimental or mass production , shorten the production cycle, reduce the effect of processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The specific embodiments of the present invention will be described below with reference to the accompanying drawings.

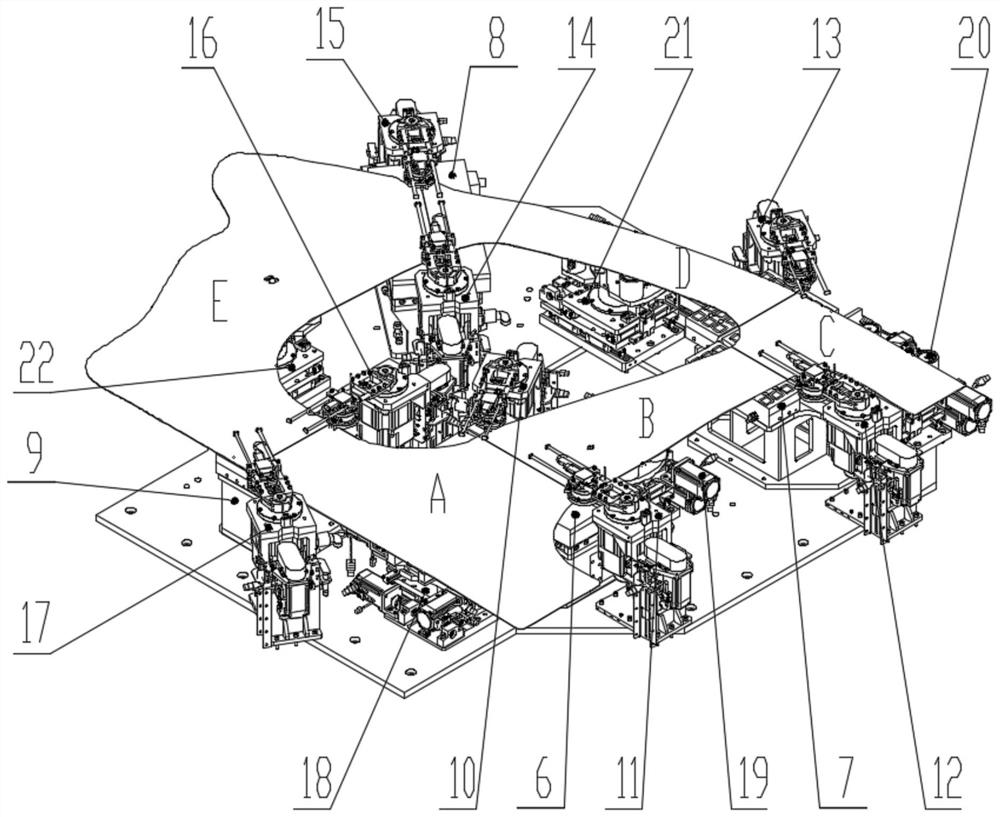

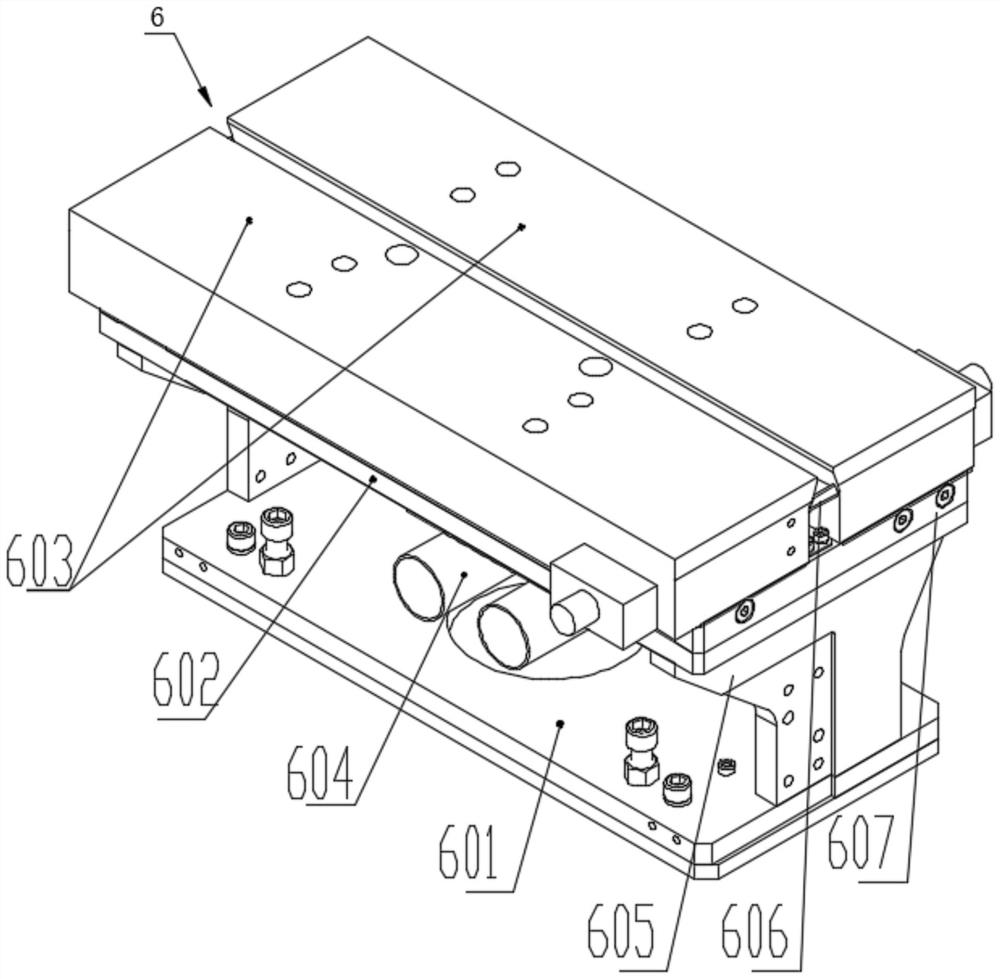

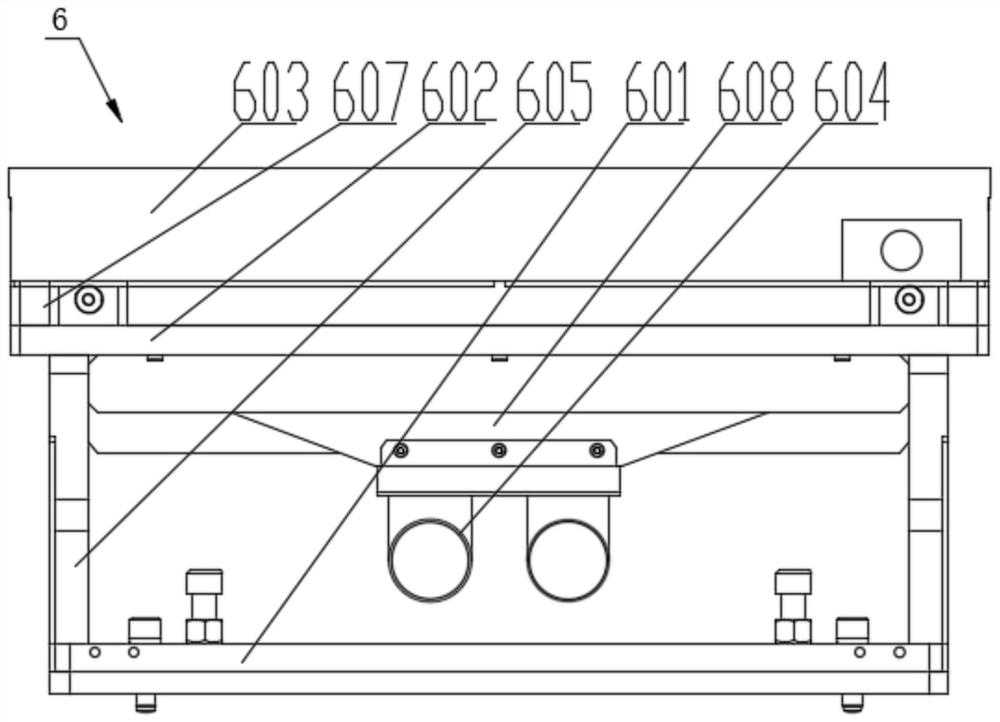

[0056] like Figure 1-Figure 9 As shown in the figure, the automatic assembling fixture for laser tailor-welded steel plates for automobile door ring in this embodiment includes a workbench, and the upper surface of the workbench is fixedly installed with multiple sets of electromagnet assembly components, multiple sets of visual camera mechanisms and multiple sets of welding drive mechanisms; the specific installation It is: including multiple sets of electric electromagnet assembly components fixed on the workbench at intervals, each set of electromagnet assembly components is installed with a welding drive mechanism on the workbench beside it, and both sides of each set of electromagnet assembly components are installed with vision The camera mechanism, the workpiece to be welded is placed on the top of the electromagnet assembly component, by comb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com