Pipe end face burr removing device based on product quality engineering

A technology of product quality and engineering, applied in the direction of machine tools, grinding drive devices, grinding workpiece supports, etc. suitable for grinding workpiece edges, to achieve the effect of improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

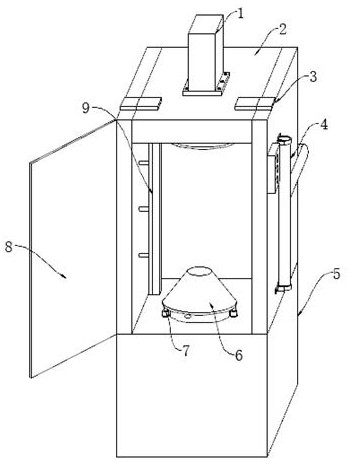

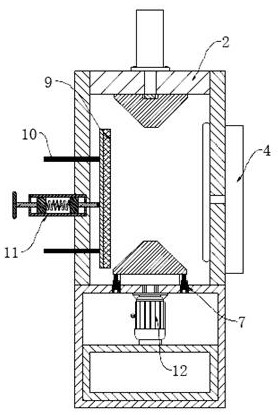

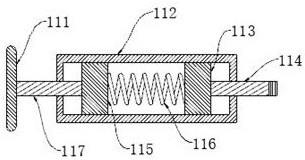

[0024] DETAILED DESCRIPTION: When in use, first place the pipe on the lower clamping seat 6, activate the hydraulic rod 1, and the hydraulic rod 1 drives the upper clamping seat to move downwards, so as to achieve a perfect balance between the upper clamping seat and the lower clamping seat. The pipe fittings between the holders 6 are fixed, wherein the upper clamping seat and the lower clamping seat 6 are designed in the shape of a truncated cone, which can meet the grinding needs of pipes with different diameters; the grinding strip 9 located on the side of the processing frame 2 It is in contact with the surface of the pipe fitting to clean the burrs on the surface of the pipe fitting, and the grinding strip 9 is fixed in position by the anti-tilt rod 10. This design can prevent the grinding strip 9 from tilting so that the force acting on the surface of the pipe fitting is uneven. The design greatly improves the uniformity of pipe grinding, which meets the needs of lean pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com