High-temperature rotor rotary sealing structure, mounting method and compensation pressure control method

A rotary sealing and rotor technology, applied in furnace control devices, furnace components, furnaces, etc., can solve problems such as leakage of flue gas and poor sealing effect, and achieve the effect of avoiding leakage, long service life and avoiding direct failure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

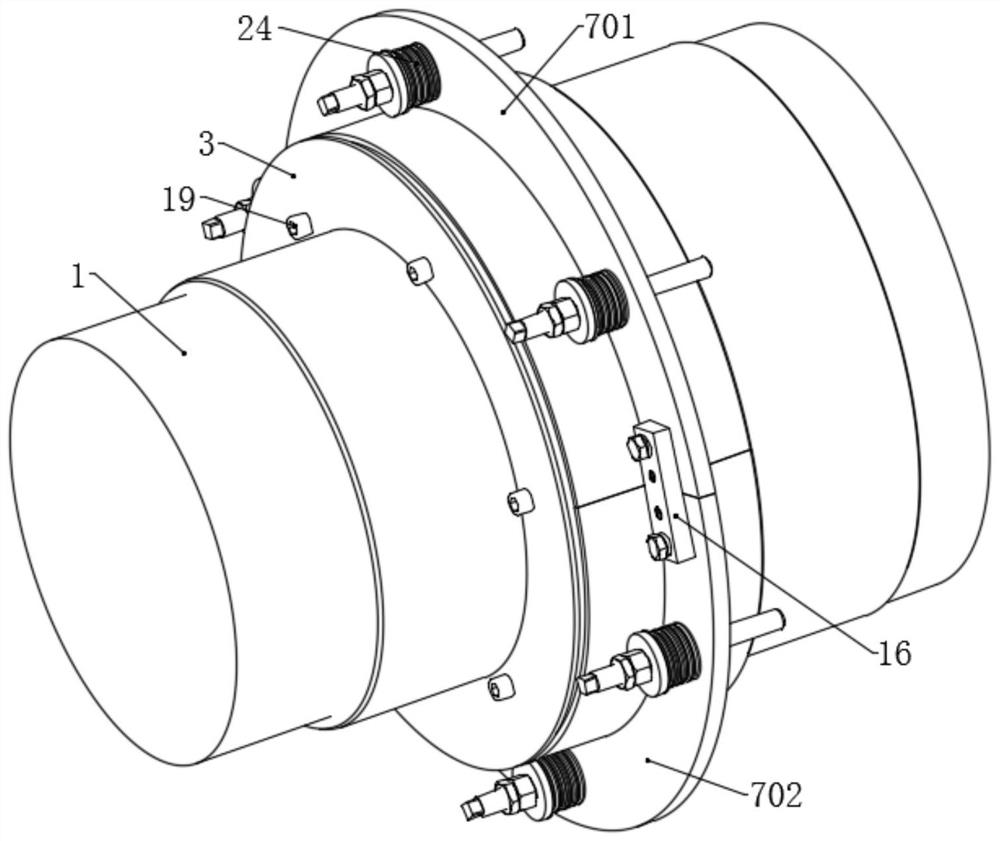

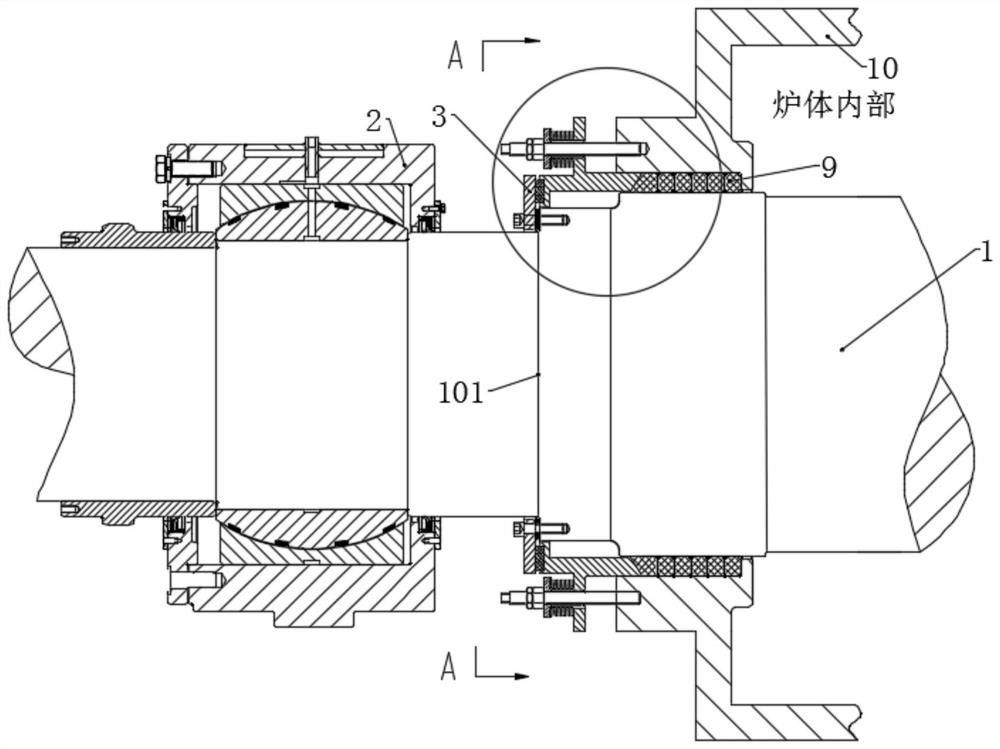

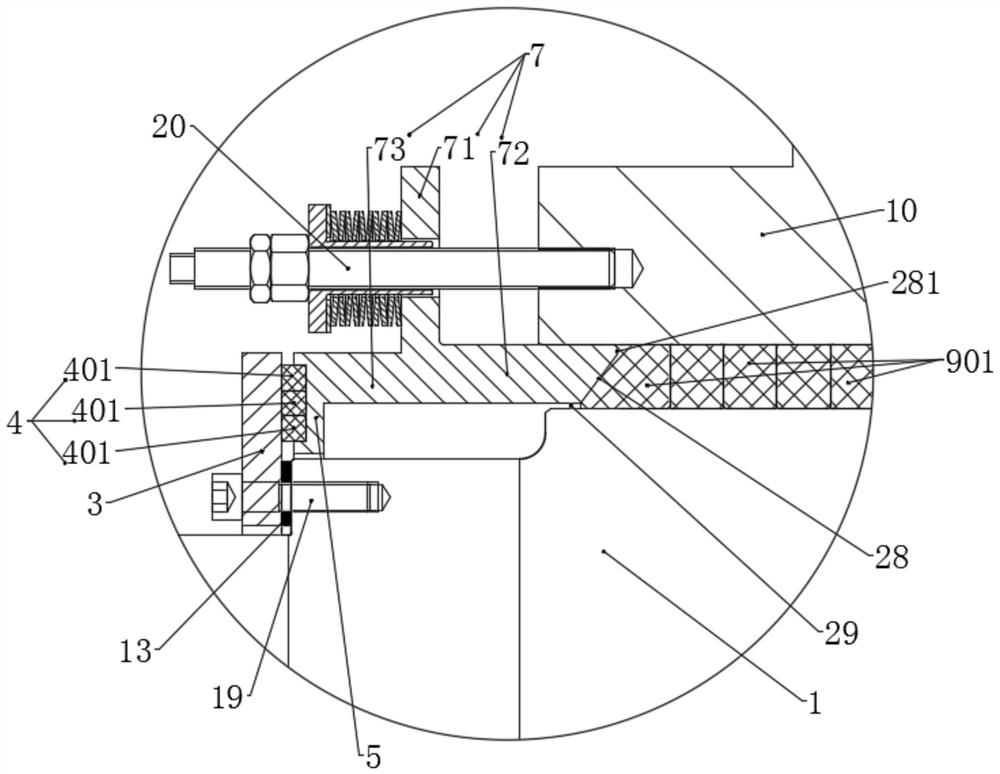

[0089] This embodiment provides a high-temperature rotor rotary sealing structure, which can be referred to Figure 1-4 , including an axial seal 9, a gland 7, an end cover 3, a first radial seal 4 and a second radial seal 13 that are coaxially arranged with the rotor 1 and sleeved on the outside of the rotor 1;

[0090] The axial seal 9 is used to be placed in the gap cavity enclosed between the furnace body 10 and the rotor 1 , and the gland 7 is arranged on the furnace body 10 along the axial direction of the rotor 1 . and the end cover 3, the pressure cover 7 is detachably connected to the furnace body 10 and can press the axial seal 9 along the axial direction of the rotor 1, and the pressure cover 7 is along its axial direction An end face pressing plate 5 is provided at one end away from the axial seal 9, the end face pressing plate 5 is arranged coaxially with the rotor 1, and the first radial seal 4 is arranged on the end face pressing plate 5 and the end face pressin...

Embodiment 2

[0103] This embodiment provides a high-temperature rotor rotary sealing structure, see figure 1 and Figure 7-13 , compared with Embodiment 1, the difference is that the connecting part 71 of the gland is connected to the end face of the furnace body 10 through a plurality of the first compensation devices, and the first compensation devices are used as detachable connection furnaces The structure of the body and the gland 7 can also compensate for the pressing effect on the axial seal 9; Guide grooves 27, the telescopic guide grooves 27 are arranged along the circumferential direction of the rotor 1, and a second compensation device is arranged in the telescopic guide grooves 27.

[0104] see Figure 10-13 , the first compensation device includes a screw 20, a locking nut 14, a guide sleeve 22 and a disc spring group 24, the screw 20 is arranged along the axial direction of the rotor 1, the locking nut 14, the guide sleeve 22 and The disc spring groups 24 are all located o...

Embodiment 3

[0110] This embodiment provides a high-temperature rotor rotary sealing structure, see Figure 16-22, which is different from Embodiment 2 in that the structures and arrangements of the first compensation device and the second compensation device are different.

[0111] In this embodiment, as Figure 19-20 As shown, the first compensation device includes a gland hydraulic cylinder 8 and a lock nut 14, the body of the gland hydraulic cylinder 8 is connected to the outside of the furnace body 10, and the gland of the gland hydraulic cylinder 8 The hydraulic rod 81 passes through the connecting portion 71 and is locked by corresponding to the locking nut 14 , and the gland hydraulic rod 81 can drive the connecting portion 71 to move in the axial direction of the rotor 1 . When the gland 7 includes an upper gland 701 and a lower gland 702 , the upper gland 701 and the lower gland 702 are provided with the same number of connecting holes for gland hydraulic rods 81 .

[0112] Com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com