High-temperature sodium heat pipe filling device and method

A filling device and high-temperature sodium technology, applied in the field of high-temperature sodium heat pipe filling devices, can solve the problems of inability to meet quantitative and cleanliness, poor cleanliness, limited heat transfer performance of sodium heat pipes, etc., and achieve the standard and feasible filling process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to better illustrate the present invention, the present invention is further described with reference to examples and accompanying drawings:

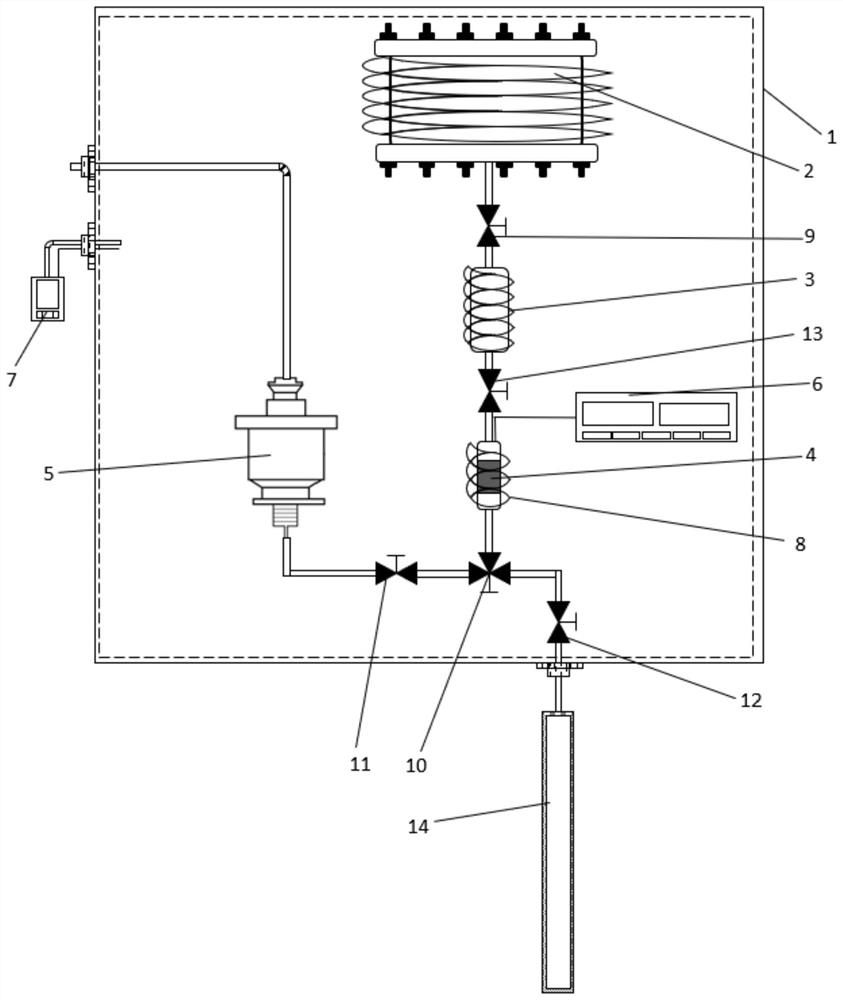

[0018] like figure 1 As shown in the figure, a high-temperature sodium heat pipe quantitative filling device of the present invention includes a transparent sealed box 1, a sodium storage tank 2, a filter tank 3, a known volume tank 4, a vacuum pump 5, a vacuum gauge 6, a humidity controller 7, an electric heating 8, the isolation valve 9 under the sodium storage tank, the isolation valve 10 under the known volume tank, the isolation valve 11 on the molecular pump, the isolation valve 12 for the heat pipe, the isolation valve 13 under the filter tank, and the shell 14 for the heat pipe; among them, the sodium storage tank 2 , filter tank 3, known volume tank 4, vacuum pump 5, vacuum gauge 6, electric heating wire 8, isolation valve under sodium storage tank 9, isolation valve under known volume tank 10, isolation valve o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com