Method for researching structure and function recovery rule of soil in open pit coal mine dumping site

A soil structure, open-pit coal mine technology, applied in the preparation of test samples, soil material testing, and material analysis by observing the impact on chemical indicators, etc. problem, to achieve the effect of natural recovery, simple and easy to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] For Shenbao Energy Group Opencast Mine Dump Site Opencast Coal Mine Dump Site:

[0044] The time of soil dumping on the west-facing slope was 2016, and the ecological restoration was carried out that year. The elevation of the platform at the top of the slope is 711m, and there are 9 steps in total. The spacing between adjacent steps is 5m. The length is 3.5km, and the bottom of the long slope at the lower edge of the bottom step is 4.3km long; the method includes the following steps:

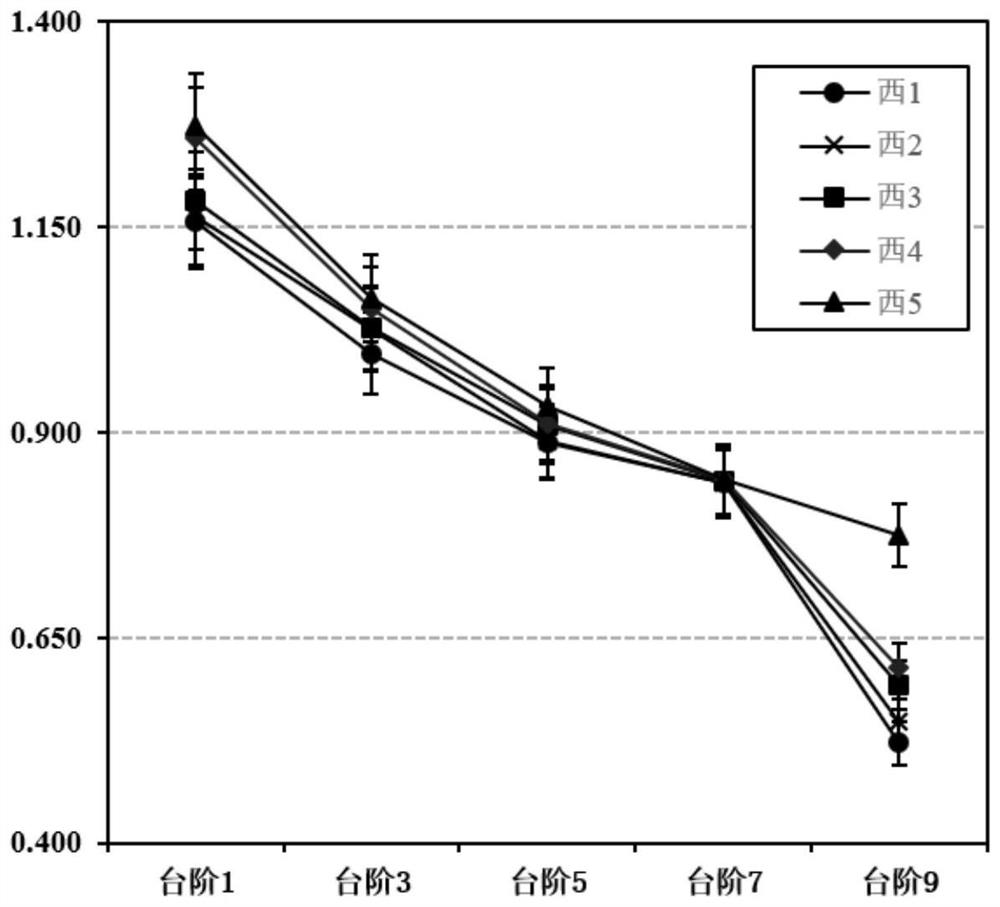

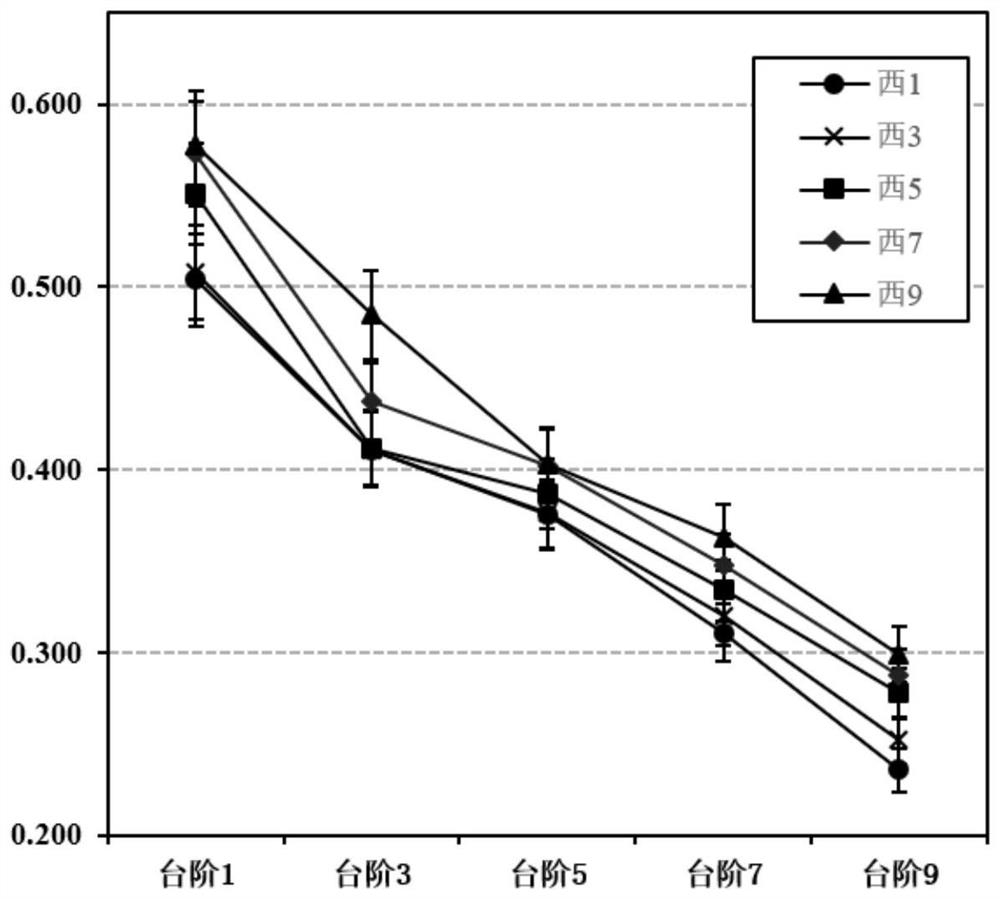

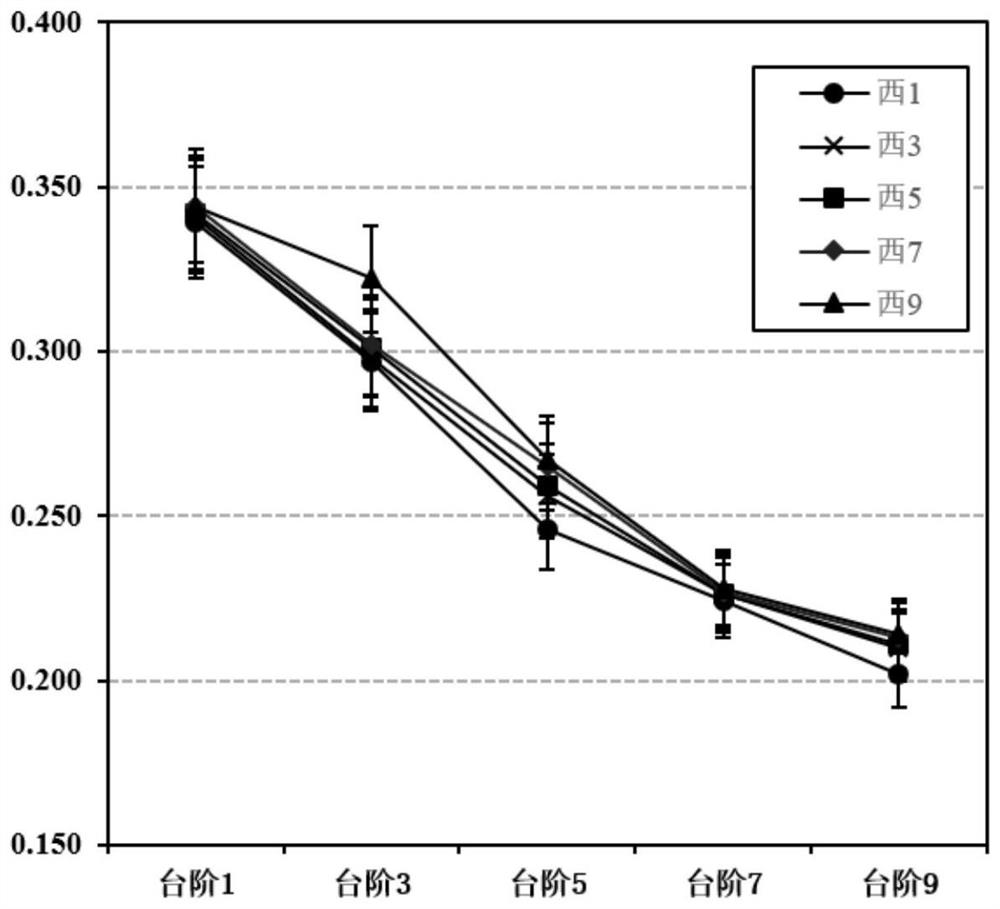

[0045] (1) Five transects are set at intervals along the lateral direction of the west-facing slope surface, and the five transects are respectively set along the slope direction of the west-facing slope surface, and the spacing between adjacent transects is 15m;

[0046](2) On each sample belt, sample points are respectively set on the slope where step 1, step 3, step 5, step 7 and step 9 are located;

[0047] (3) For each sample point, two soil quadrats are set up on the slope, in the...

Embodiment 2

[0064] It differs from Example 1 only in that:

[0065] For Shenbao Energy Group Opencast Mine Dump Site Opencast Coal Mine Dump Site:

[0066] The slope surface of the south-facing slope reached the boundary in 2013, and the ecological restoration was carried out that year. The elevation of the platform at the top of the slope is 693m, and there are 7 steps in total. The spacing between adjacent steps is 5m. The length of the bottom step is 1.6km, and the bottom of the long slope at the lower edge of the bottom step is 2.7km long;

[0067] In step (1), three transects are set at intervals along the lateral direction of the south-facing slope surface, and the three transects are respectively set along the slope direction of the south-facing slope surface, and the spacing between adjacent transects is 15m. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com