Automatic insertion method and system based on visual guidance

A vision-guided and automatic technology, applied in the connection/disconnection direction of the connecting device, can solve the problems of socket extrusion damage of the BMU board, affecting the test results of the station, and the scrapping of the BMU board, so as to reduce the risk of extrusion damage, The effect of shortening the insertion time and avoiding indentation and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

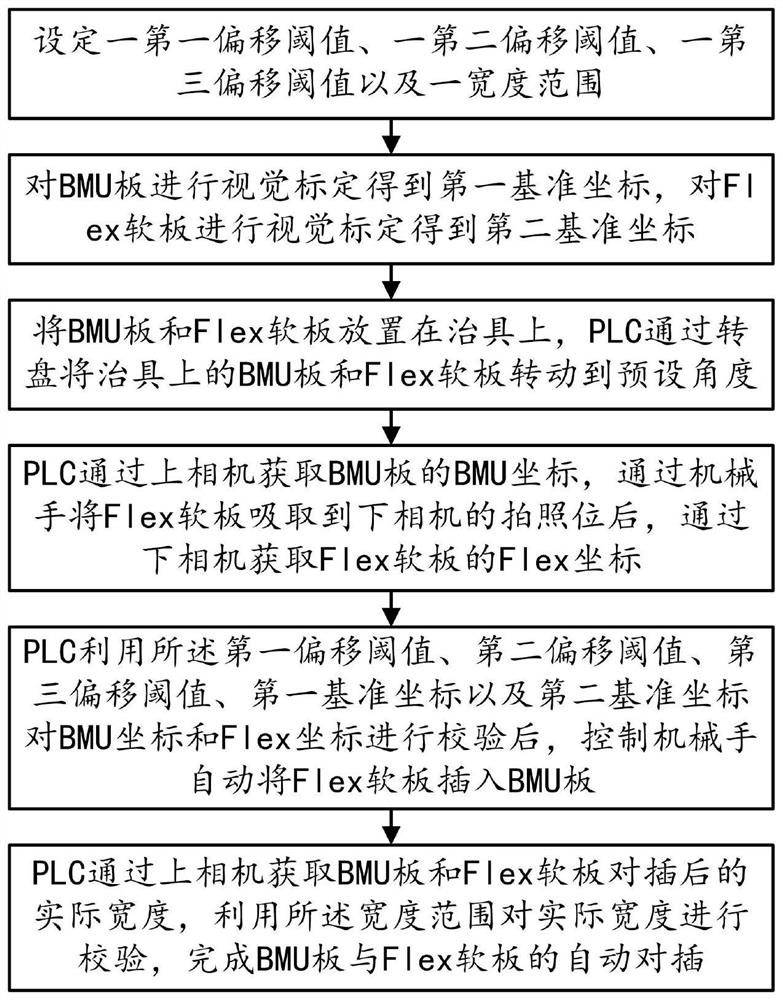

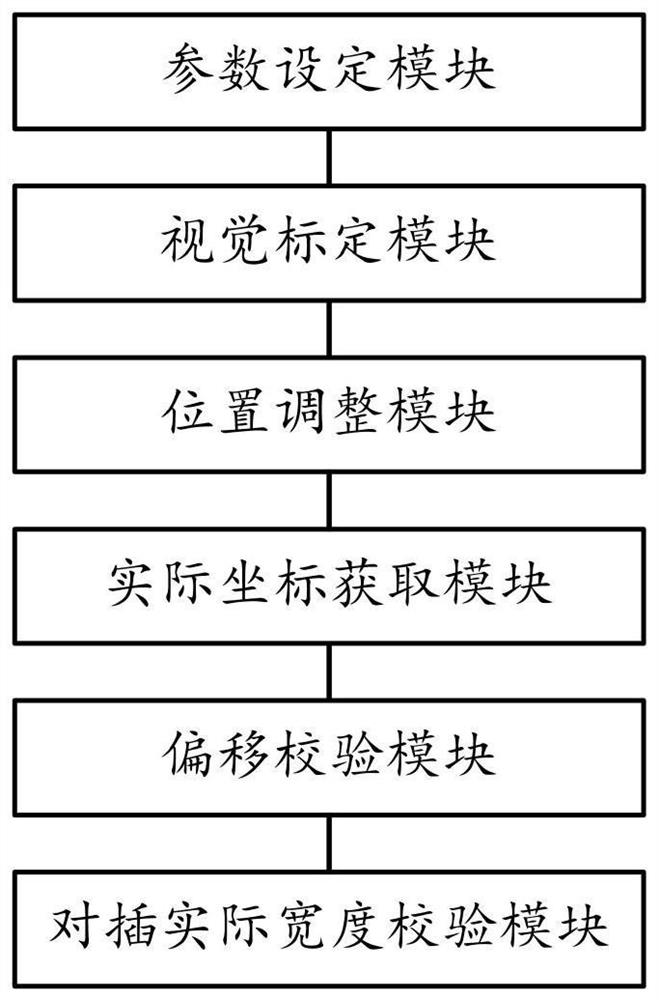

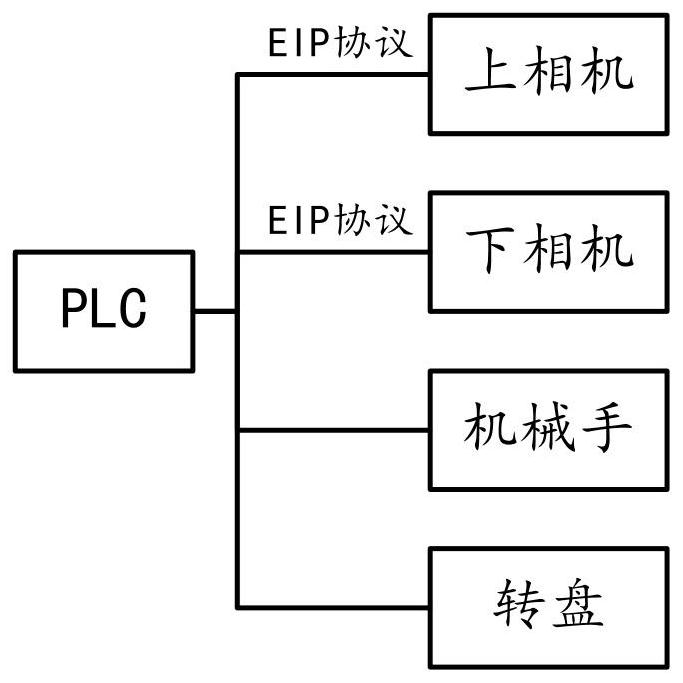

[0048] The general idea of the technical solutions in the embodiments of the present application is as follows: the risk of damage to the BMU board is reduced by the automatic insertion of the manipulator, and the insertion time is shortened; through the set first offset threshold, second offset threshold, third offset threshold Offset threshold and width range Check the offset and total offset of the BMU board and the Flex board, and check the actual width after the BMU board and the Flex board are plugged together to avoid excessive offset. As a result, the plugging fails, and the situation that the plugging is not in place or the plugging is too far is found in time, so as to improve the accuracy, efficiency and quality of the plugging of the BMU board and the Flex soft board.

[0049] Please refer to Figure 1 to Figure 3 As shown, a preferred embodiment of a visual guidance-based automatic plugging method of the present invention includes the following steps:

[0050] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com