Sealing device and sealing element

A technology for sealing devices and sealing components, which is applied to engine components, engine seals, mechanical equipment, etc., and can solve problems such as the loss of the sealing effect that cannot be detected

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

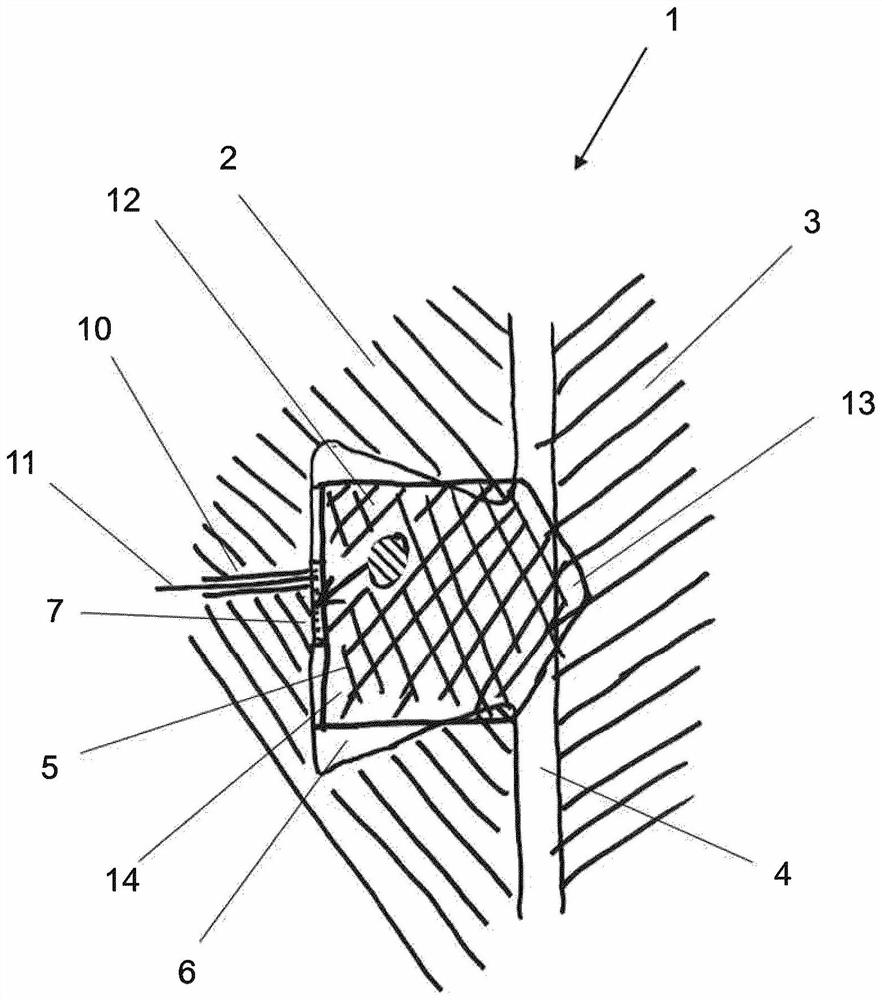

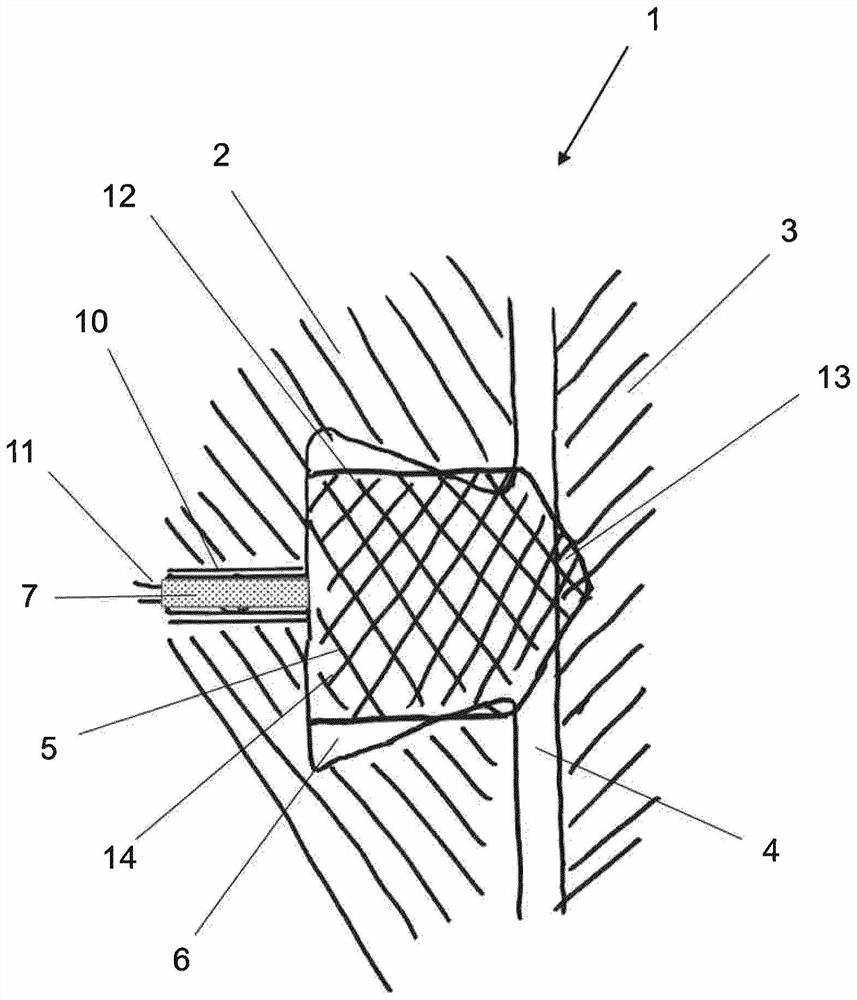

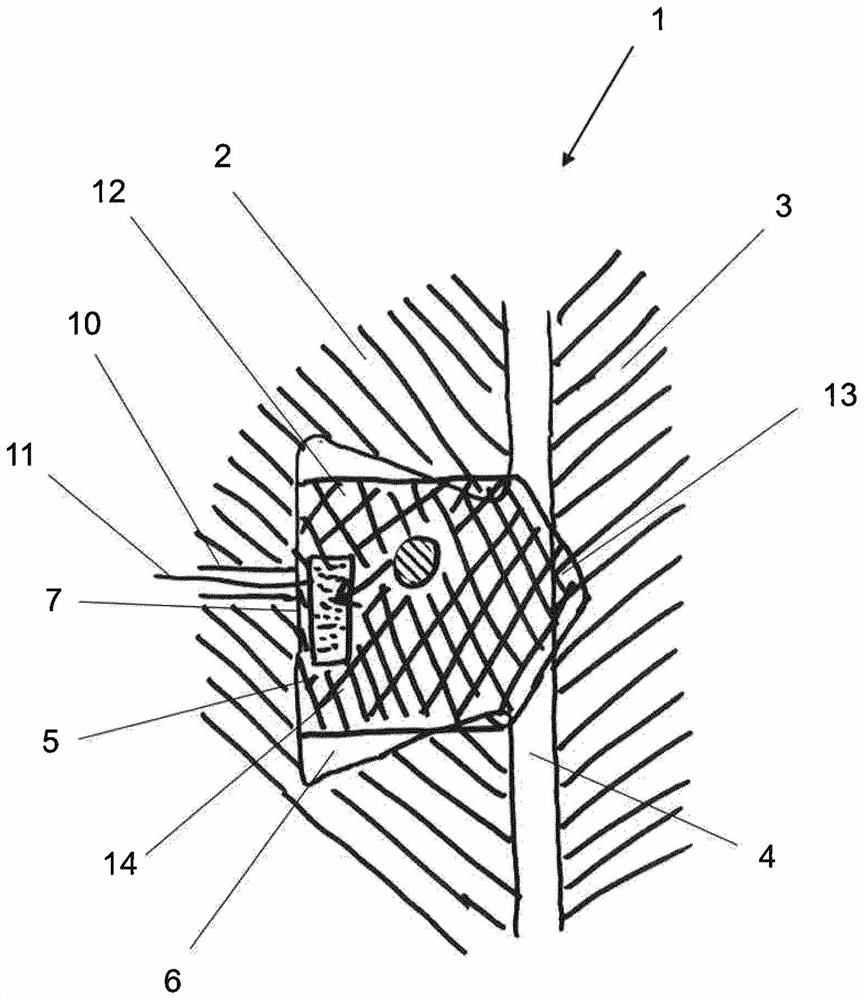

[0030] The figures show a sealing device 1 with a first machine element 2 and a second machine element 3 which define a gap 4 . In this design, the first machine element 2 is the housing, and the second machine element 3 is a rod that moves in translation relative to the first machine element 2 .

[0031] In an alternative design, the sealing device 1 is arranged in the valve seat screening section. Here, the first machine element 2 is the housing and the second machine element 3 is the valve stem.

[0032] A sealing element 5 is arranged in the gap 4 . Here, the sealing element 5 separates the space to be sealed from the surrounding environment. The medium to be sealed, eg lubricating oil, is present in the space to be sealed. In principle, other designs of the sealing device with alternative designs of the first machine element 2 , the second machine element 3 and the sealing element 5 are also conceivable.

[0033]In order to accommodate the sealing element 5 , an accom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com