PCB positioning and conveying device based on correction and fixation

A PCB circuit board and conveying device technology, which is applied in the direction of conveyor control devices, conveyors, conveyor objects, etc., can solve problems such as time-consuming, production line production rate decline, and PCB board position accuracy, so as to ensure stability degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to describe the technical solutions of the present invention more clearly and completely, the present invention is further described below with reference to the accompanying drawings.

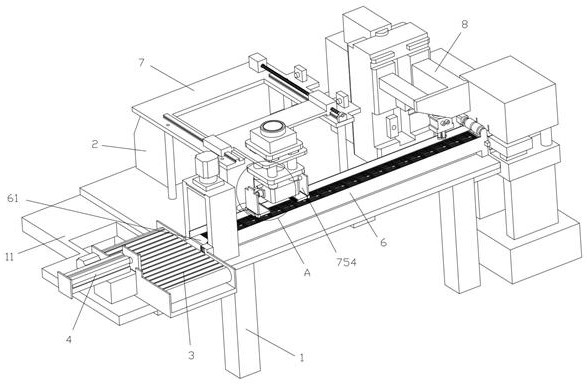

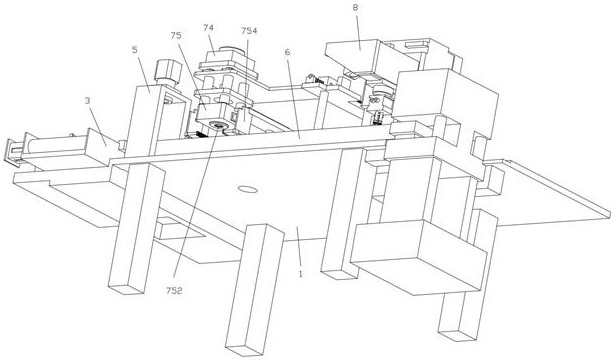

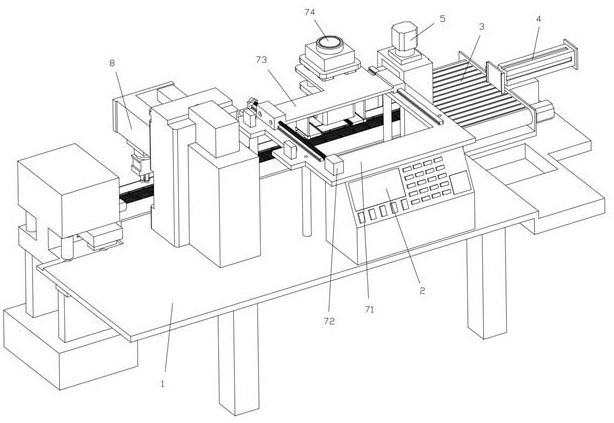

[0032] Please refer to Figure 1-Figure 8 , The present invention proposes a positioning and conveying device based on the correction and fixing of the PCB circuit board, including a support table 1, a control box 2, a feeding and conveying device 3, a pushing device 4, a first image acquisition device 5, a positioning and conveying device 6, a clamping pendulum Positive mechanism 7, patch device 8, a fixing plate 11 is provided on one side of the support table 1, the feeding conveying device 3 is fixedly placed on the fixing plate 11, and the pushing device 4 is fixedly connected to the side of the feeding conveying device 3 and is conveyed toward the positioning Device 6, the positioning and conveying device 6 is fixedly placed on the support table 1 and is set perpendicular t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com