Asphalt laying device for road

A technology for laying device and road asphalt, which is applied to household refrigeration devices, roads, roads, etc., can solve the problems of inability to adjust uneven pavement in time, and inability to carry out compaction work, and achieve the effect of stable temperature control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

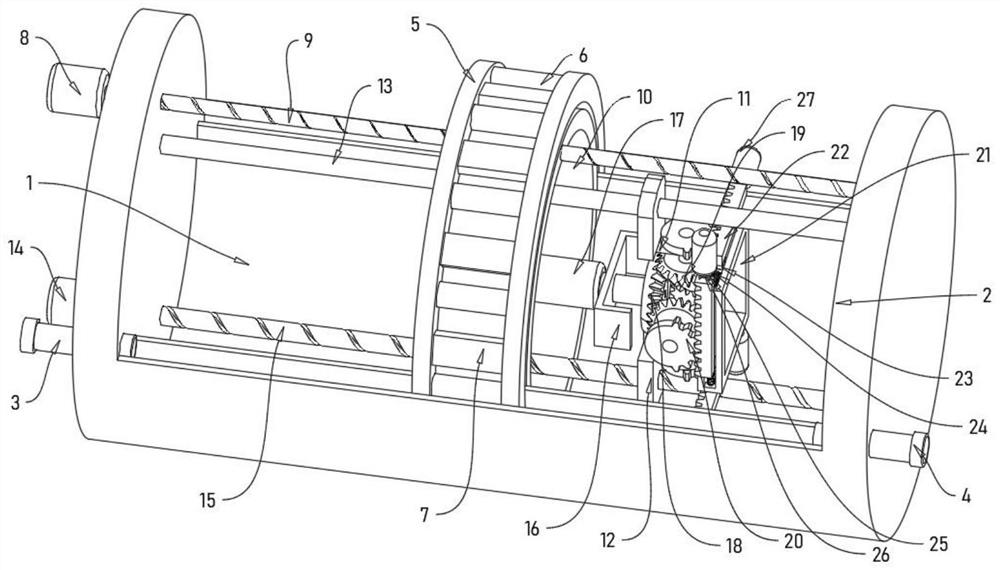

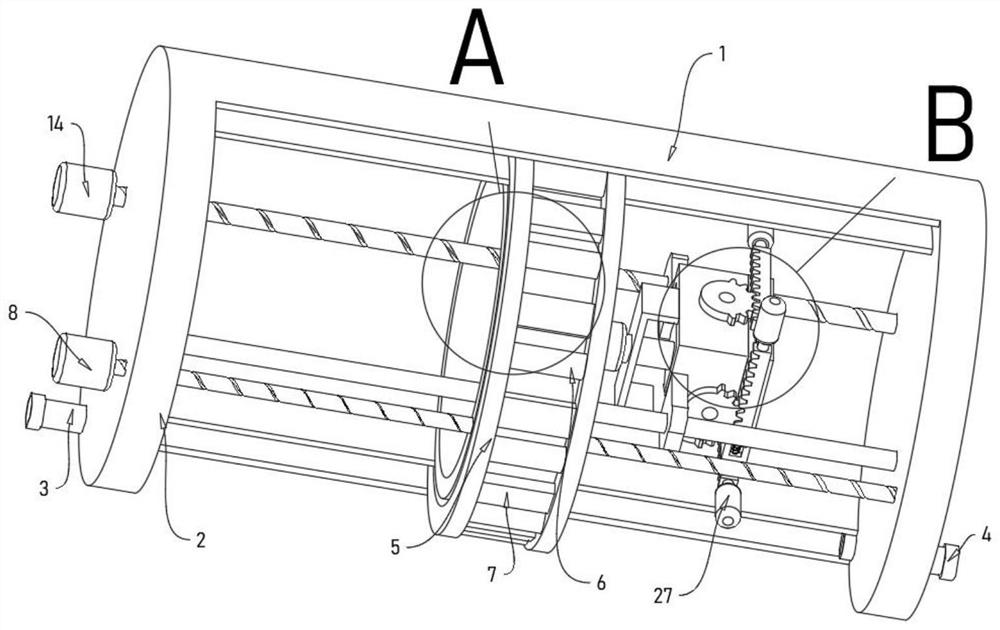

[0032] Example: please refer to Figure 1 to Figure 8 :

[0033] The present invention proposes a road asphalt paving device, comprising: a roller 1,

[0034] The main body of the drum 1 is a circular tubular structure, and the inner wall of the drum 1 is also provided with a two-way through cavity, and side plates 2 are fixedly connected to the left and right sides of the drum 1. The side plates 2 are circular structures, and two The side plate 2 is used to close the cavity opened inside the drum 1, and a supply pipe 3 is also installed on the outside of the two side plates 2. The supply pipe 3 communicates with the cavity opened inside the drum 1, and in the supply pipe 3 One end away from the side plate 2 is also provided with a swivel 4, one end of the frame 11 is fixedly connected with a mounting frame 16, one end of the mounting frame 16 is also mounted with a motor C17, one end of the motor C17 is also mounted with a helical gear A18, The outer side of the A18 is also...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com