Automatic discharging device for intelligent garbage cleaning trolley

An automatic unloading device and garbage technology, which is applied in cleaning methods, road cleaning, waste collection and transfer, etc., can solve the problems of inability to achieve effective separation and storage of garbage liquid, low unloading efficiency, and difficulty in effectively unloading, etc., to achieve garbage Convenient and effective, avoid cleaning work, avoid the effect of accelerated corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

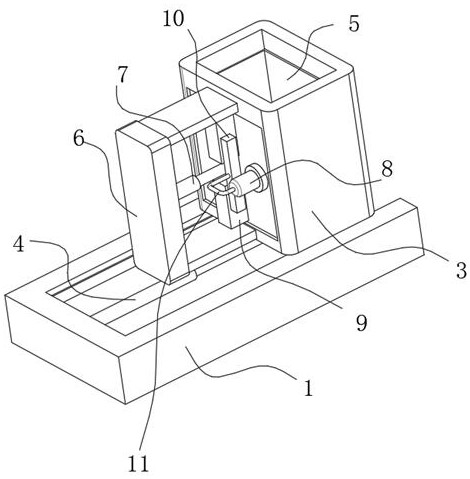

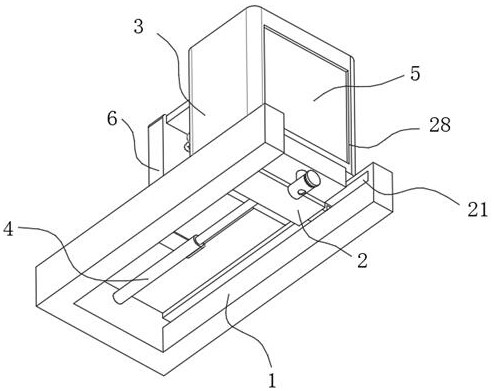

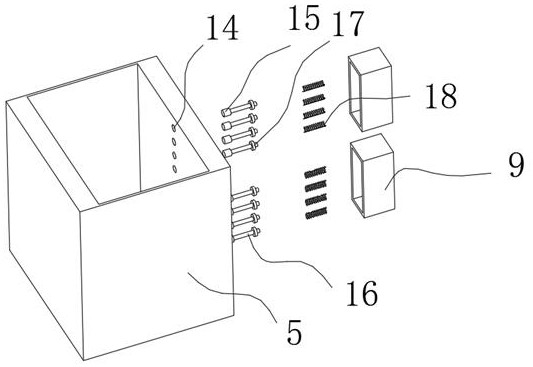

[0034] The first embodiment: as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Image 6 As shown, when unloading is required, the No. 1 telescopic rod 4 pushes the movable seat 2 to move, so that the side plate 19 on the side of the movable seat 2 slides along the chute 21, and at the same time makes the mounting frame 3 and the collecting frame 5 move to At the rear end of the fixed frame 1, the No. 2 telescopic rod pushes the collection frame 5 to move to the outside. As the collection frame 5 slides out from the side of the installation frame 3, a large amount of garbage falls directly from the lower end of the collection frame 5, and the air pump 8 is activated at the same time. The air pump 8 passes the air into the communication box 10 through the air pipe 11, and activates the heating pipe 13, so that the hot air enters the air box 9 through the communication hole 12, and pushes the sealing plug 15 on the end surface of the sleeve rod 16 to move out of ...

no. 2 example

[0044] Second embodiment: as figure 1 , figure 2 , Figure 7 and Figure 8 As shown, when the garbage is fed into the collection frame 5 through the suction pipe of the garbage cleaning trolley, the liquid in the accumulated garbage gradually flows down and enters the storage box 23 along with the water hole 22 on the top surface of the installation frame 3 In the storage box 23, a large amount of liquid waste waste water is gradually stored in the storage box 23. When the unloading of the waste in the collection frame 5 is completed, the sealing cover 26 is rotated laterally so that the liquid waste waste liquid in the storage box 23 passes through the liquid outlet hole on the bottom surface of the No. 2 pipe 25. 27 discharge.

[0045] First, by opening the water hole 22 on the bottom surface of the installation frame 3, and installing the storage box 23 on the bottom surface of the installation frame 3, the storage box 23 is communicated with the water hole 22. The liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com