Large-area curtain wall keel structure and installation method thereof

A large-area, keel technology, applied to walls, building components, building structures, etc., can solve problems such as the deflection of the main keel’s circumferential fixed angle, installation error, and the influence of curtain wall units, so as to achieve enhanced integrity and stability. The effect of improving force performance and improving the degree of fit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

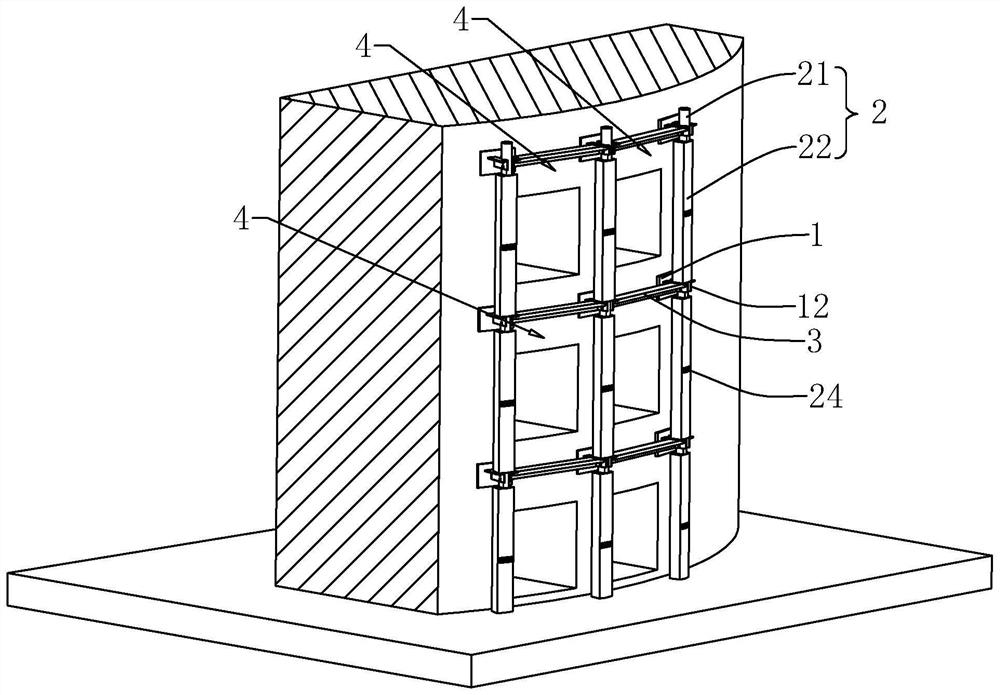

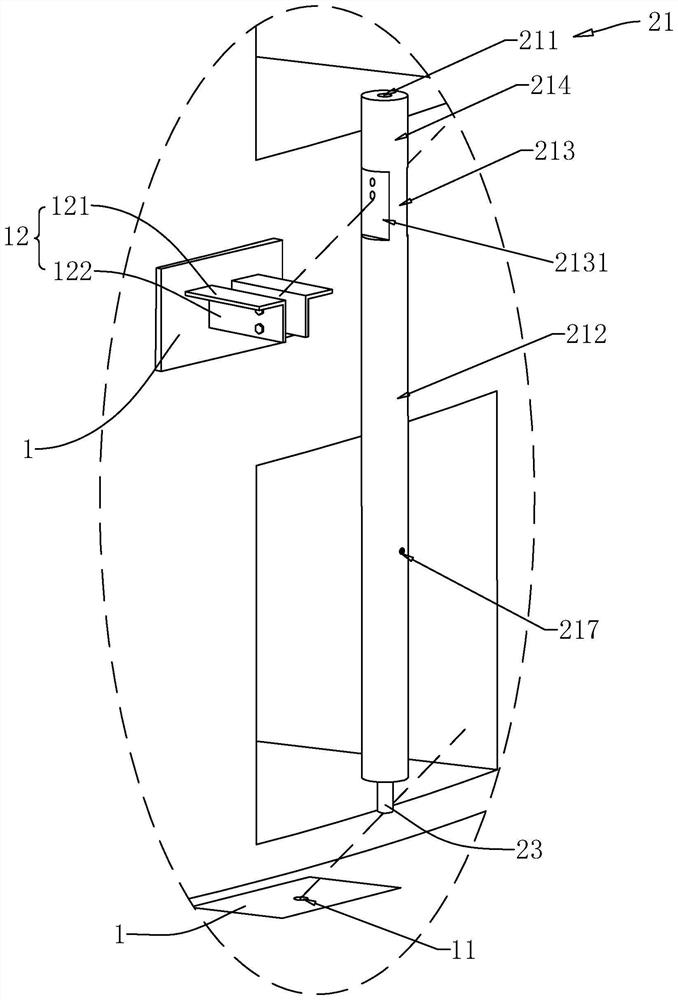

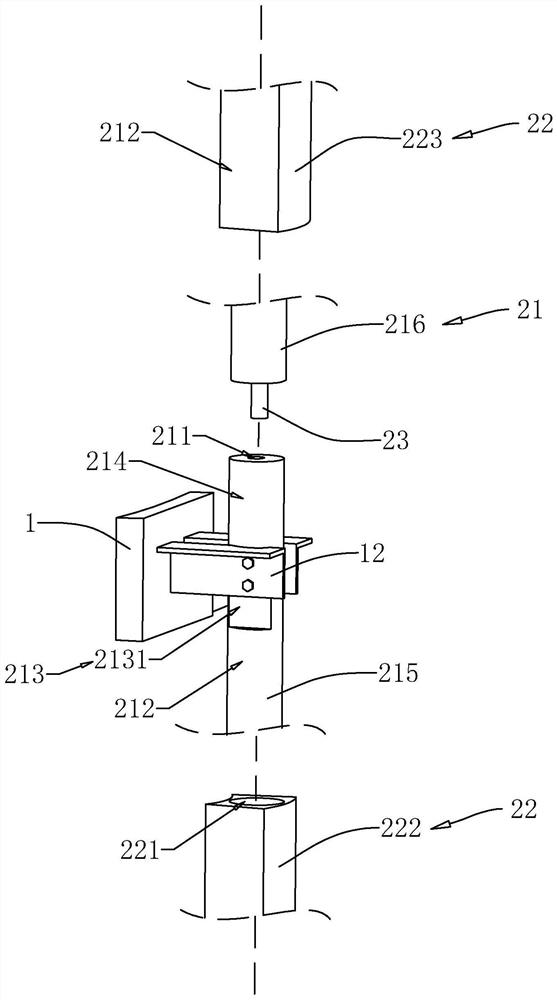

[0045] Attached to the following Figure 1-4 This application will be described in further detail.

[0046] In a first aspect, the embodiments of the present application disclose a large-area curtain wall keel structure. In addition, the specific construction situation in this embodiment is described with an arc-shaped curtain wall perpendicular to the building foundation. In the field situation, the outer side wall of the building is an arc-shaped surface perpendicular to the building foundation surface.

[0047] refer tofigure 1 The overall keel structure is a grid-like light steel structure laid on the outer wall of the building. It includes a plurality of metal embedded parts 1, a plurality of vertical main keels 2 and a plurality of horizontal secondary keels 3. Before pouring the building concrete, the metal embedded parts 1 are fixedly connected to the reinforcement cage in the building according to a predetermined fixed position. , and one side of the embedded part 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com