Low-flow-resistance under-pressure plugging fluid connector

A low flow resistance, connector technology, applied in couplings, mechanical equipment, etc., can solve problems such as product failure, leakage, and seal failure, and achieve the effects of reducing eddy current interference, increasing fluid flux, and reducing flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to more fully understand the technical content of the present invention, the technical solutions of the present invention are further introduced and described below with reference to specific embodiments, but are not limited thereto.

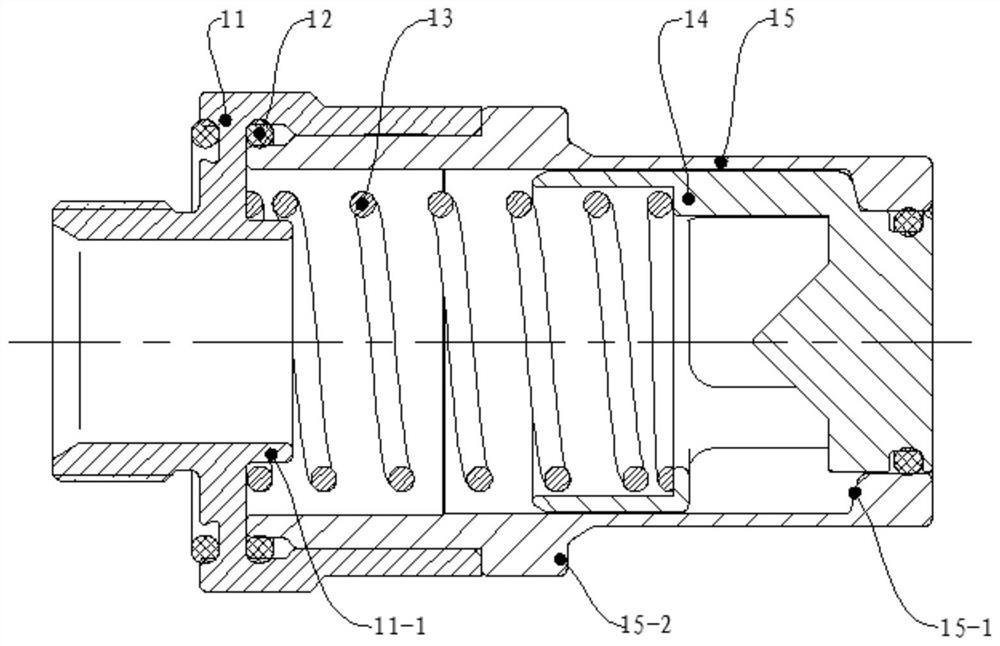

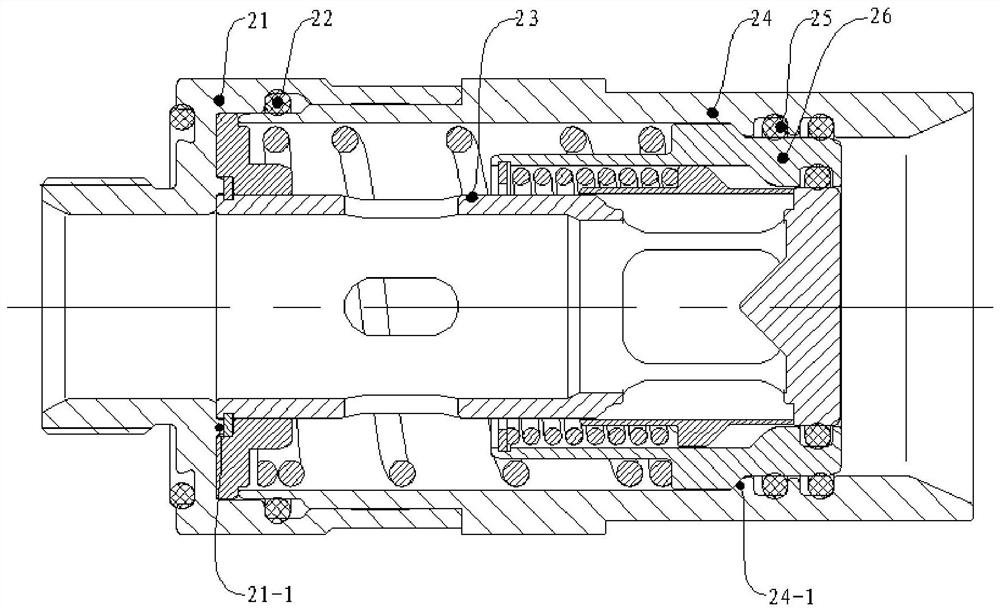

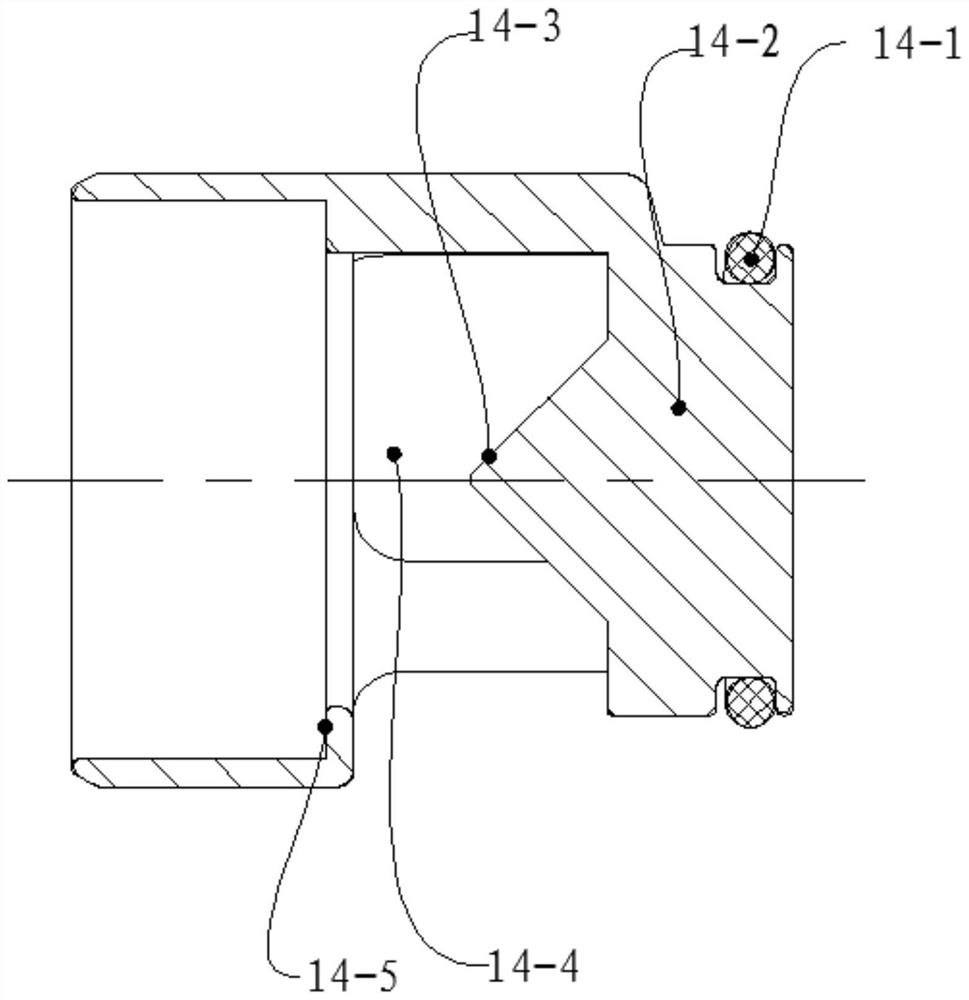

[0045] combine Figure 1 to Figure 5 Further describe a low flow resistance band pressure plug-in fluid connector provided by the present invention, including: a plug 1, a first installation shell 11, a first spring positioning portion 11-1, a first sealing ring 12, a first spring 13, The first axial sliding seal assembly 14, the second sealing ring 14-1, the sliding seal 14-2, the first diverting structure 14-3, the first flow hole 14-4, the first spring limiting part 14-5 , the plug-in housing 15, the first limit part 15-1, the insertion limit part 15-2, the socket 2, the second installation shell 21, the anti-drop structure 21-1, the fourth seal ring 22, the axial fixed seal Assembly 23, axial seal assembly fixing element 23-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com