Method for testing critical characteristics of superconducting tape in multiple deformation modes

A technology of superconducting strips and critical characteristics, which is applied in the usage of superconducting elements, magnetic property measurement, measuring devices, etc. It can solve the problems of inability to adjust stress online and eliminate thermal stress disturbance errors, so as to improve accuracy and eliminate interference effect of factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

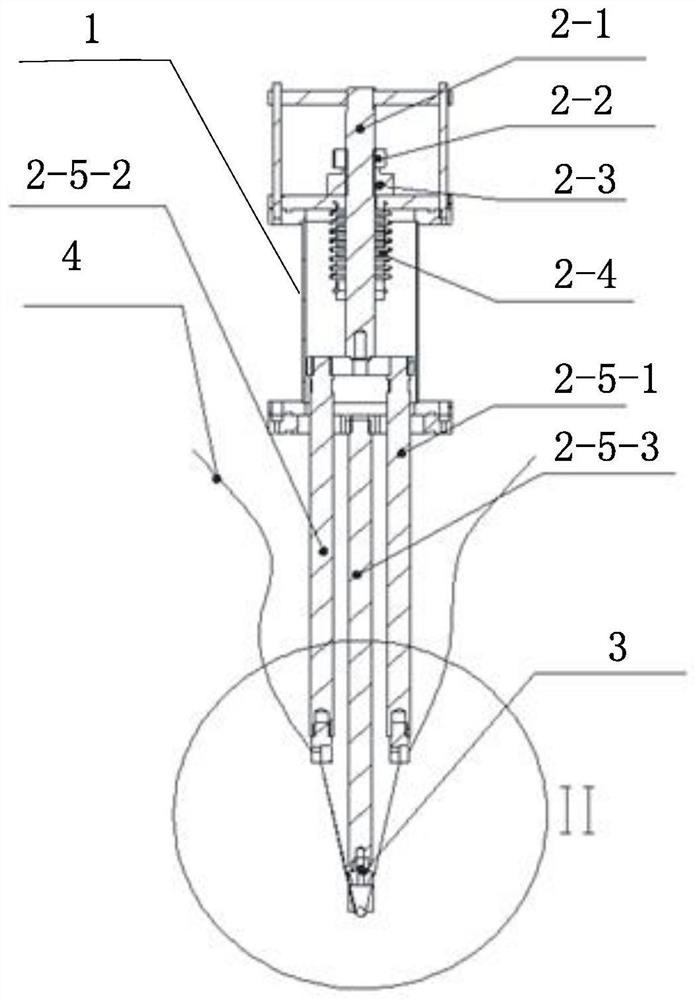

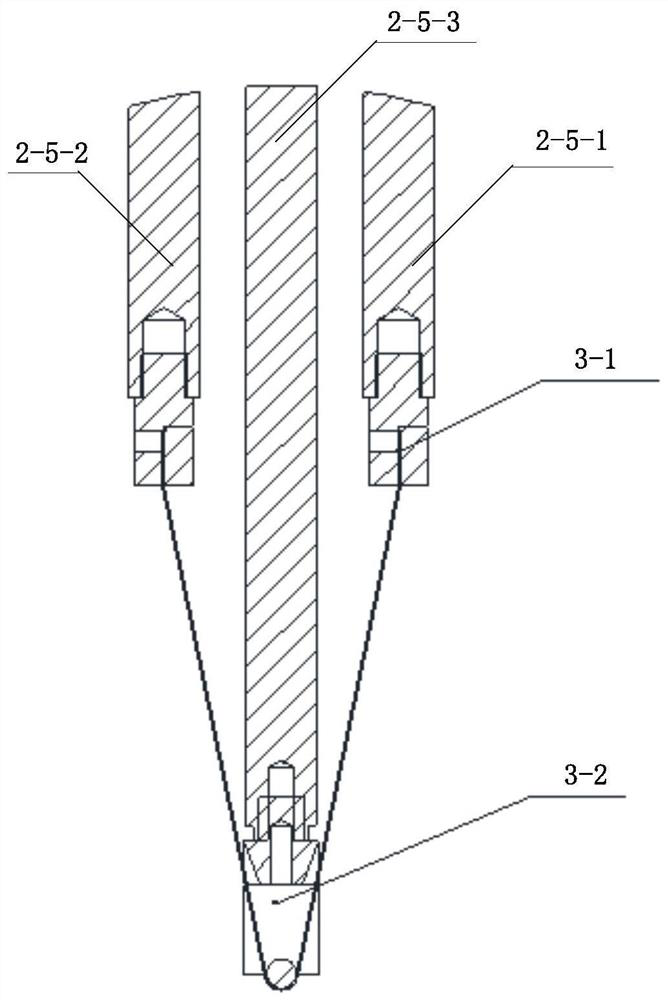

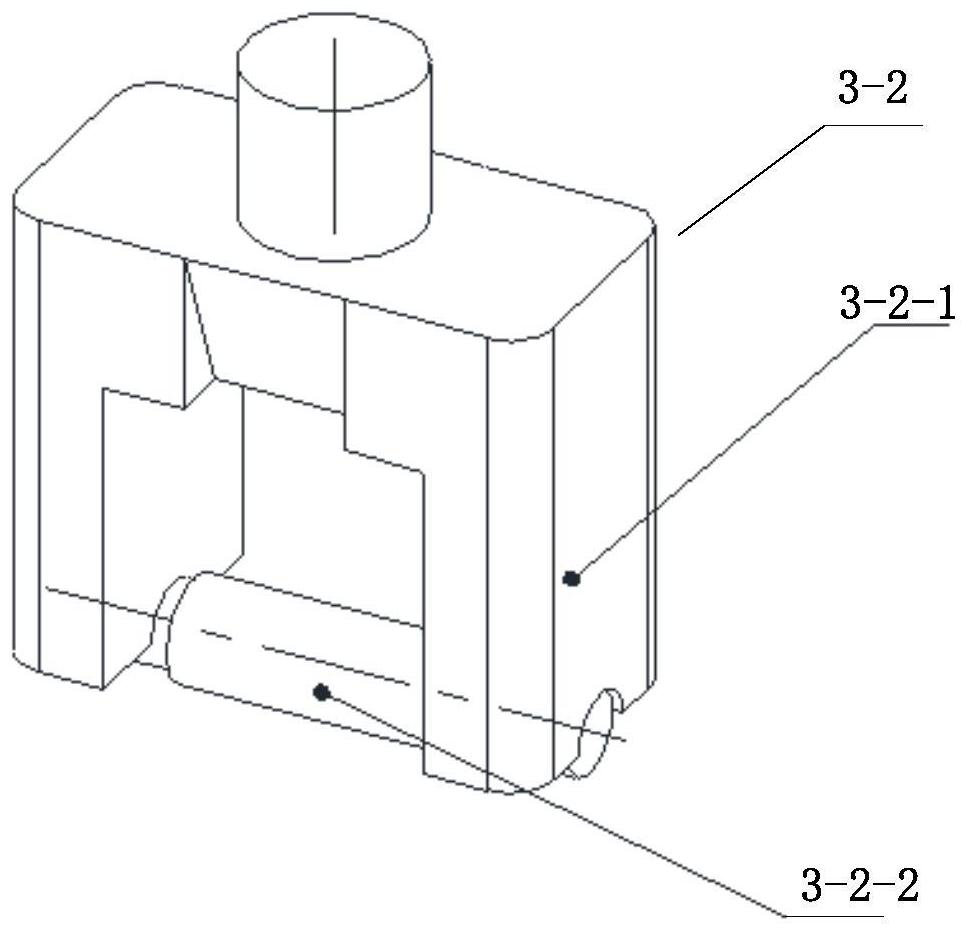

[0046] The present invention is further explained below in conjunction with accompanying drawing:

[0047] Design principle of the present invention

[0048] 1. The design principle of online adjustable stress. The key problem of adjusting stress online is to arrange the parts of the adjustable tension component 2 that operate at normal temperature and those that operate at ultra-low temperature respectively in different temperature environments, specifically: the adjustable screw 2-1, the adjustment nut 2- 2. The pressure sensors 2-3 are arranged in a normal temperature environment; the G10 tie rod 1, G10 tie rod 2, and G10 tie rod 3 are arranged in an ultra-low temperature environment; Part of the joint part, if the sealing is not done well, will produce hot gas leakage. In order to solve the problem of hot gas leakage in the joint part of the two parts, the adjustable tension component of the present invention is divided into three sections: upper, middle and lower section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com