Method for calculating maximum rotation angle of pipeline under fault action

A calculation method and technology of large turning angle, applied in the field of concrete pipes, can solve the problem of low prediction accuracy of the maximum turning angle of segmented pipes, and achieve the effect of high prediction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

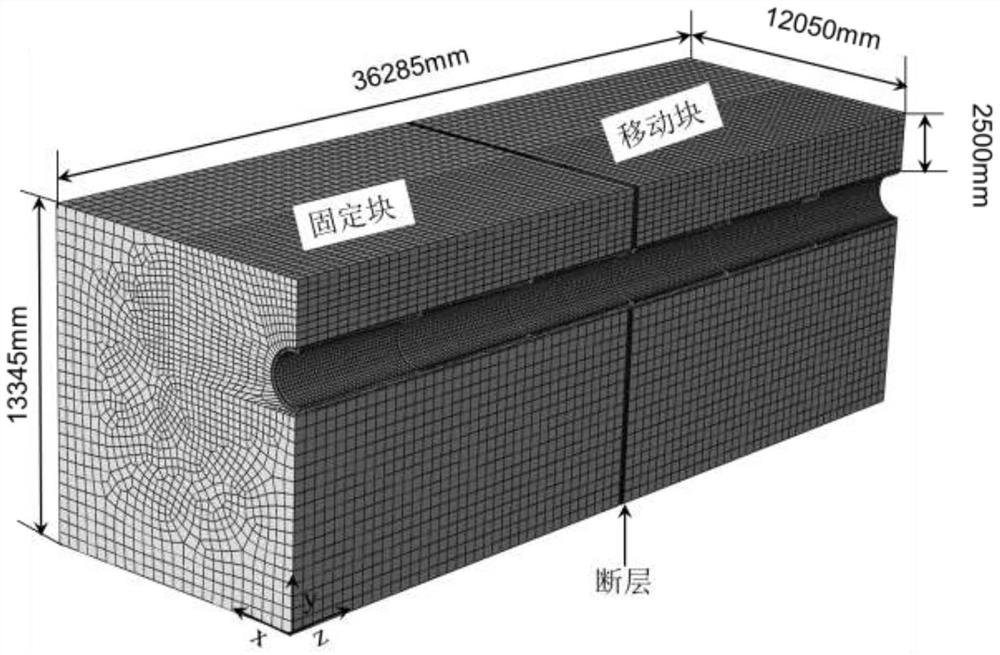

[0032] The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

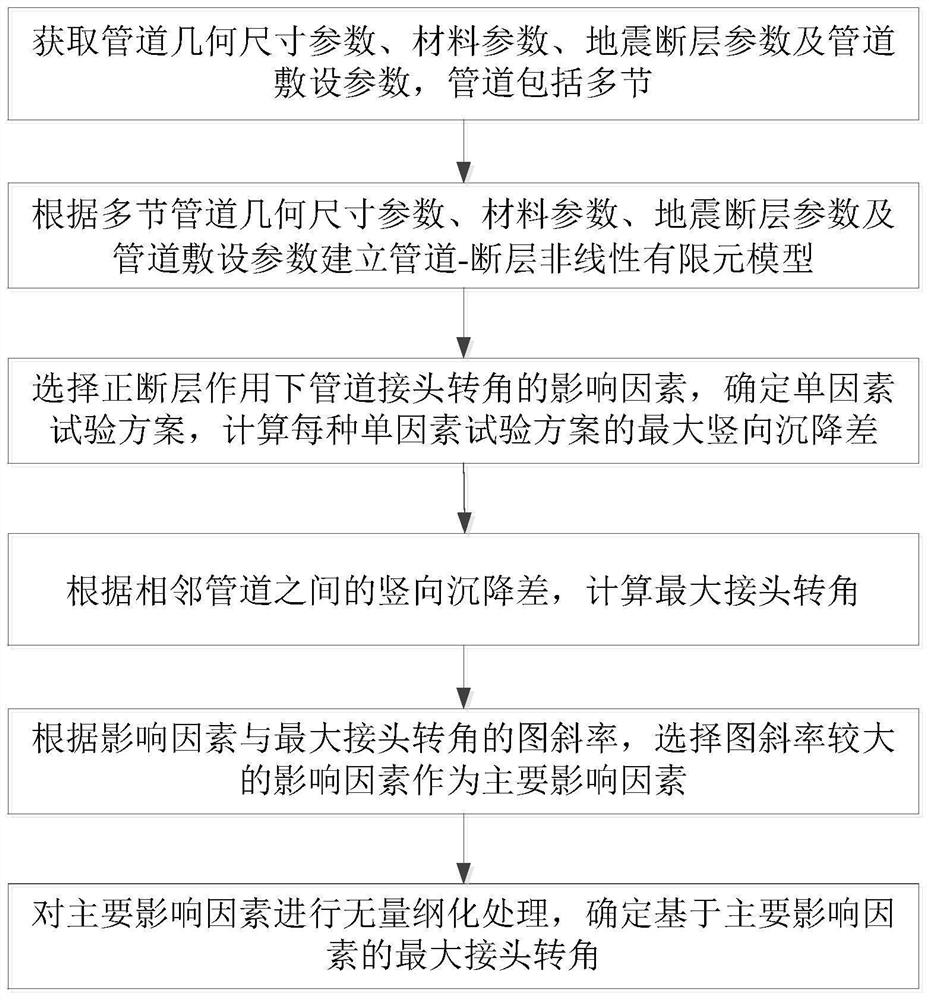

[0033] The calculation method of the maximum turning angle of the pipeline under the action of the fault, such as figure 1 shown, including the following steps:

[0034] Step 1. Obtain the geometric size parameters, material parameters, seismic fault parameters and pipeline laying parameters of the PCCP pipeline, and the pipeline includes multiple sections;

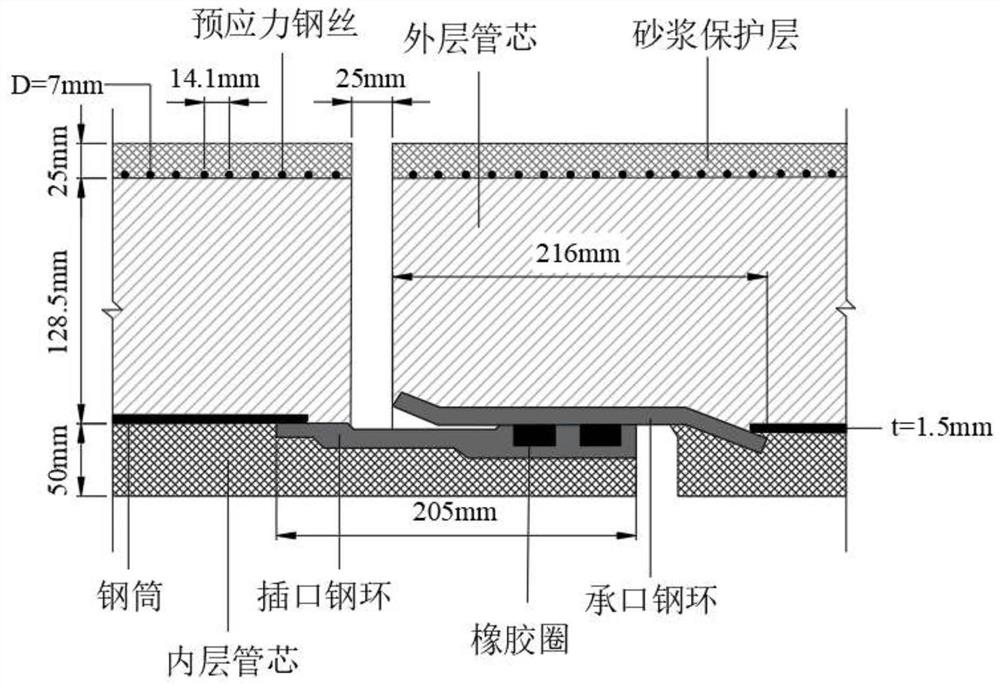

[0035] Specifically, the geometric parameters of the pipeline include the length of the PCCP single section, the inner diameter, the thickness of the inner core, the thickness of the steel cylinder, the thickness of the outer core, the thickness of the mortar, the diameter of the steel wire, the spacing between the windings, the width of the joint, the insertion length, the working pressure. The geometric size parameters used in this embodiment are shown in Table 1:

[0036] Table 1 Geo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com