Novel popcorn processing equipment and processing method thereof

A kind of processing equipment and popcorn technology, applied in the new type of popcorn processing equipment and its processing field, can solve the problems of inconvenient processing, centralized accumulation, easy sticking, etc., to facilitate packaging and storage work, avoid local accumulation, and improve efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

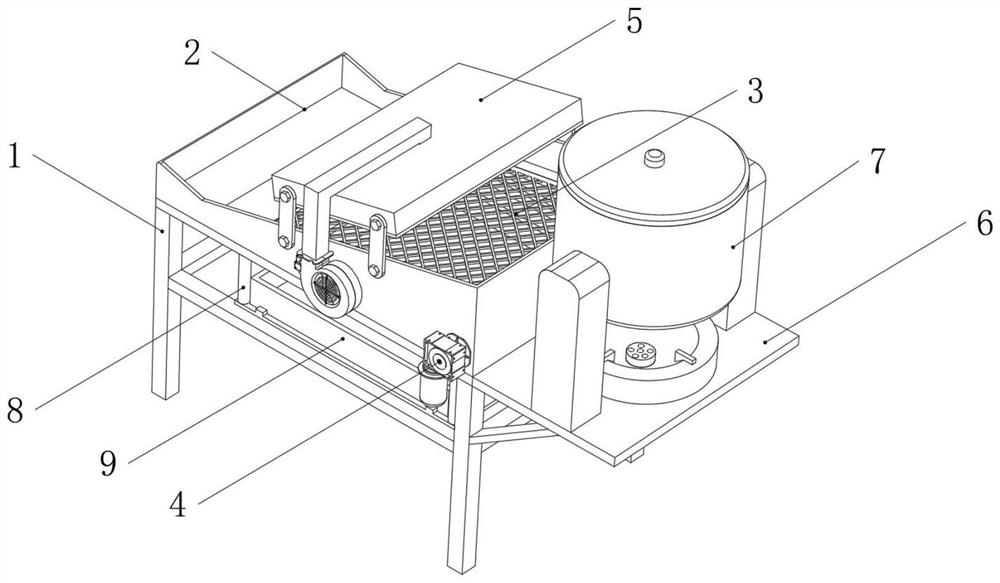

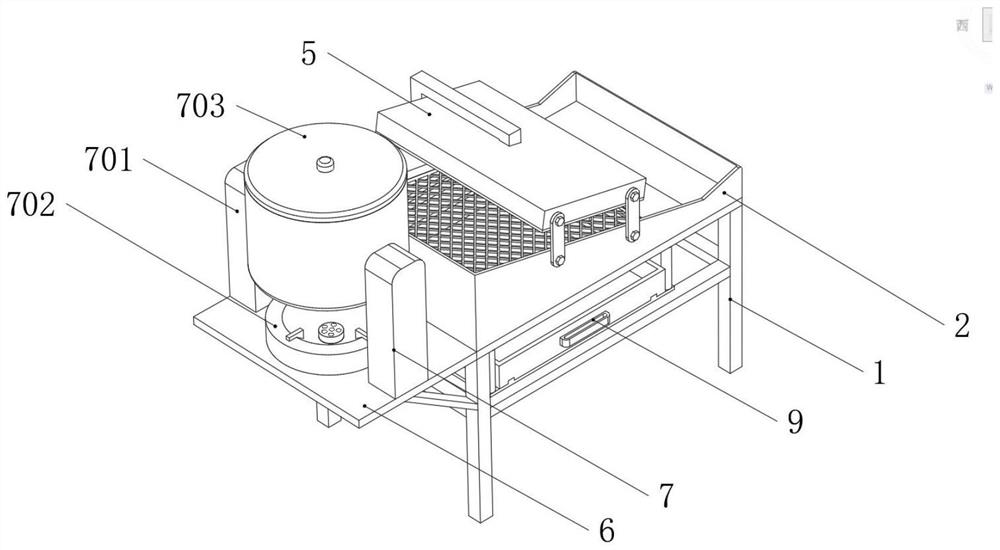

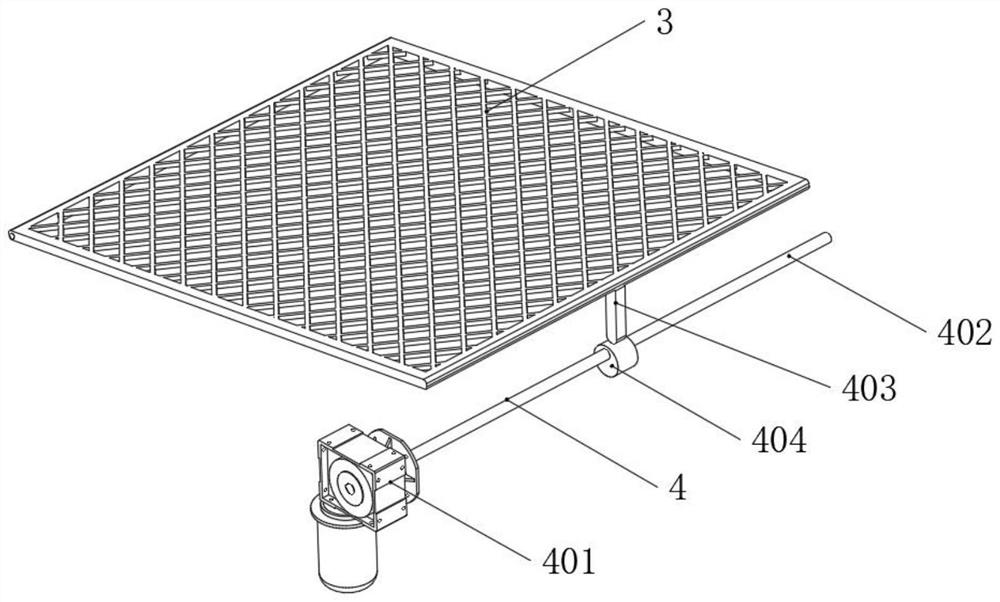

[0041] Example: as Figure 1-Figure 5 As shown, a new type of popcorn processing equipment of the present invention includes a processing table 1, the top of the processing table 1 is fixedly connected with a containing groove 2, and a screen 3 is arranged inside the containing groove 2, and between the screen 3 and the containing groove 2 A screening component 4 is provided, a cooling component 5 is provided above the container tank 2, an extension table 6 is fixedly connected to one end of the processing table 1, a production mechanism 7 is arranged on the top of the extension table 6, and a bracket is fixedly connected to the bottom of the processing table 1. The rack 8, the top of the bracket 8 is provided with a collection box 9.

[0042] Among them, the bottom of the holding tank 2 is provided with sieve holes, and the inner walls on both sides of the sieve holes are connected with one end of the screen mesh 3 through a pin shaft. The screen 3 can be used to screen out ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com