Self-adaptive clamping device of aircraft engine blade tip process table

A technology of clamping device and process table, which is applied in the direction of positioning device, clamping, manufacturing tools, etc., can solve the problems of clamping error and affecting the yield of blades, etc., and achieve the advantages of convenient use, high-efficiency mass production, and fast loading and unloading Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

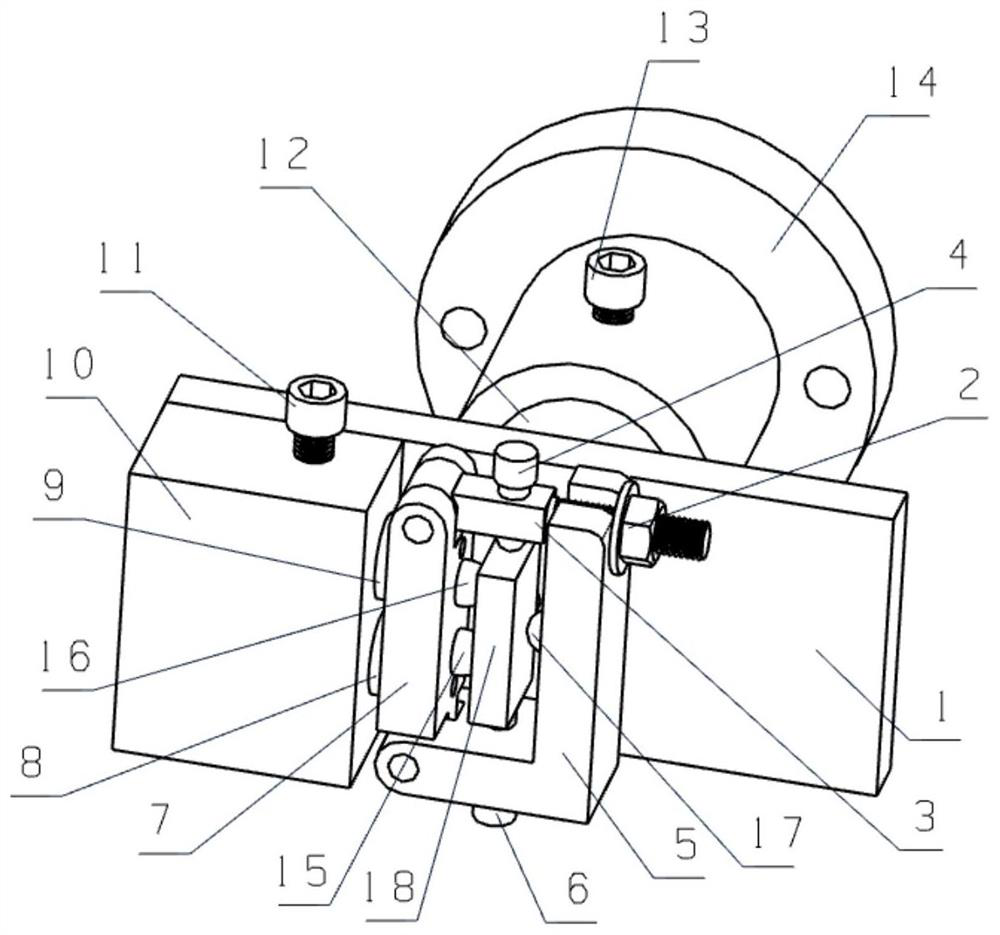

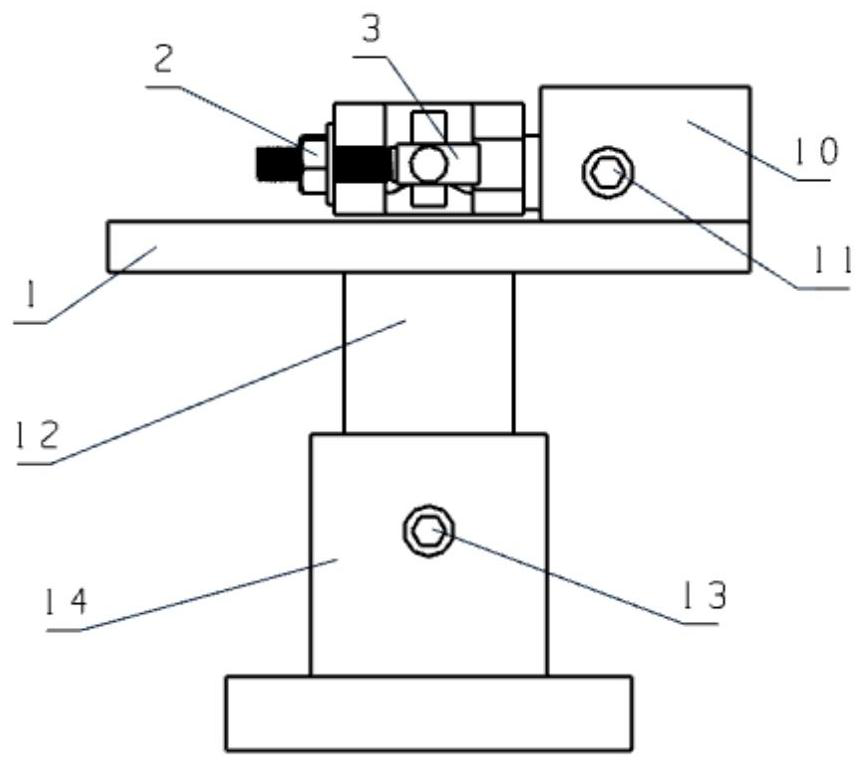

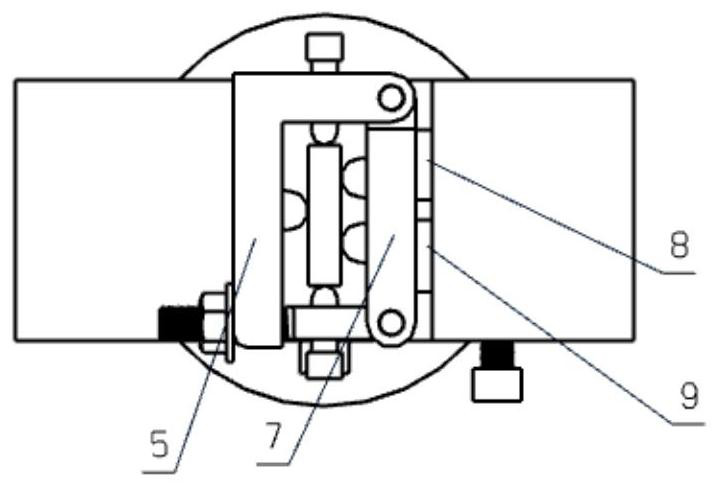

[0026] Example 1: as Figure 1 to Figure 4 As shown in the figure, an adaptive clamping device for a blade tip craft table of aero-engine blades, including a connecting plate 1, the connecting plate 1 is installed on a machine tool through a telescopic base, and the telescopic base includes a shaft sleeve 14 set on the machine tool, and is connected to One end of the shaft 12 is clearance fit, and is slidably arranged in the shaft sleeve 14. The connecting plate 1 is fixedly installed on the other end of the connecting shaft 12. The second top tightening screw 13 in the position;

[0027] An ejector box 10 is fixedly installed on the connecting plate 1 , and the first clamping block 7 is installed on one side of the ejector box 10 through a pair of ejector bars in the ejector box 10 . The top rods are the first top rod 8 and the second top rod 9, one end of the first top rod 8 and the second top rod 9 are respectively parallel, and are slidably arranged in the two sliding gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com